Storage, Troubleshooting & replacement parts, Operator’s manual – ANKOM 200 Series User Manual

Page 30

Operator’s Manual

pg. 30

Rev C 1/14/15

Check the Bag Suspender

The Bag Suspender should be checked every three to six months or if fiber values are higher than normal or

inconsistent. To check the Bag Suspender, follow the procedure detailed below.

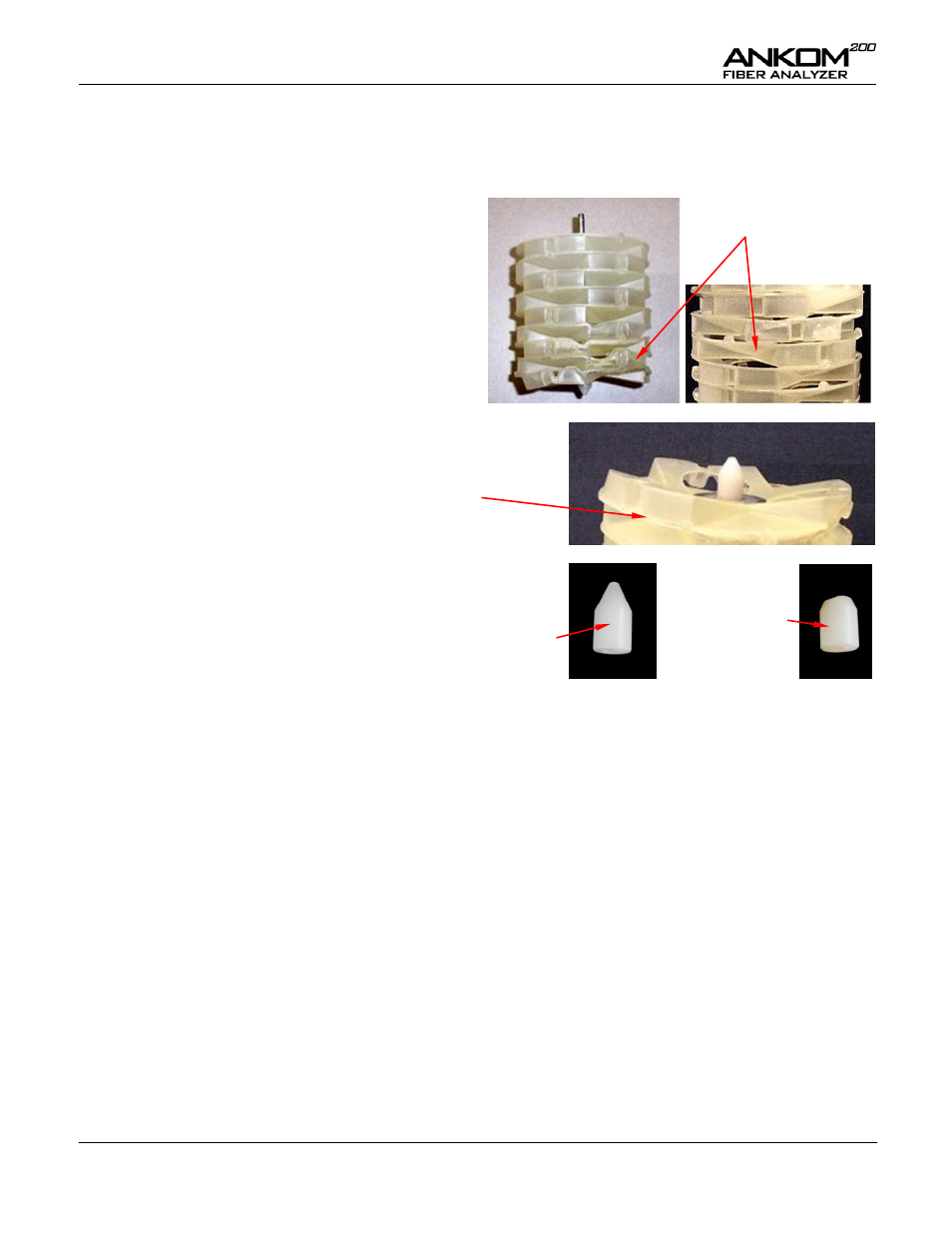

1. Check the trays for melting.

The pictures shown are examples of extreme

cases. However, for proper operation you

must replace trays that show signs of melting

or wear.

2. Check that the bottom tray is flat.

If the bottom tray is concave (see picture) the

bag suspender will catch in the vessel and

melt.

3. Check the tip for excessive wear.

Replace worn tips (see pictures).

Storage

Acid residue can corrode the instrument if left on or in the instrument. Before storing the instrument (or leaving the

instrument unused) for greater than one month, rinse the Vessel thoroughly with water using the following

procedure.

1.

Fill the Vessel with water

.

2.

Press the

A

A

G

G

I

I

T

T

A

A

T

T

E

E

button so that it is lit.

3.

After 10 minutes, press the

A

A

G

G

I

I

T

T

A

A

T

T

E

E

button so that it is NOT lit. This will turn the agitation off.

4.

Open the Exhaust Valve and exhaust the hot water.

5.

After the water has been exhausted, close the Exhaust Valve.

Troubleshooting & Replacement Parts

The ANKOM technology web site has the most current troubleshooting and replacement parts information.

Therefore, if you have any questions about the operation of your ANKOM

200

Fiber Analyzer, or if you need

replacement parts, please visit our web site at

www.ankom.com.

Melted trays

Good

Tip

Worn

Tip