Installer’s final check out procedure, Peak control, Circuit board configuration – Steffes Transmitter User Manual

Page 6

I

NSTALLATION

C

ONTINUED

…

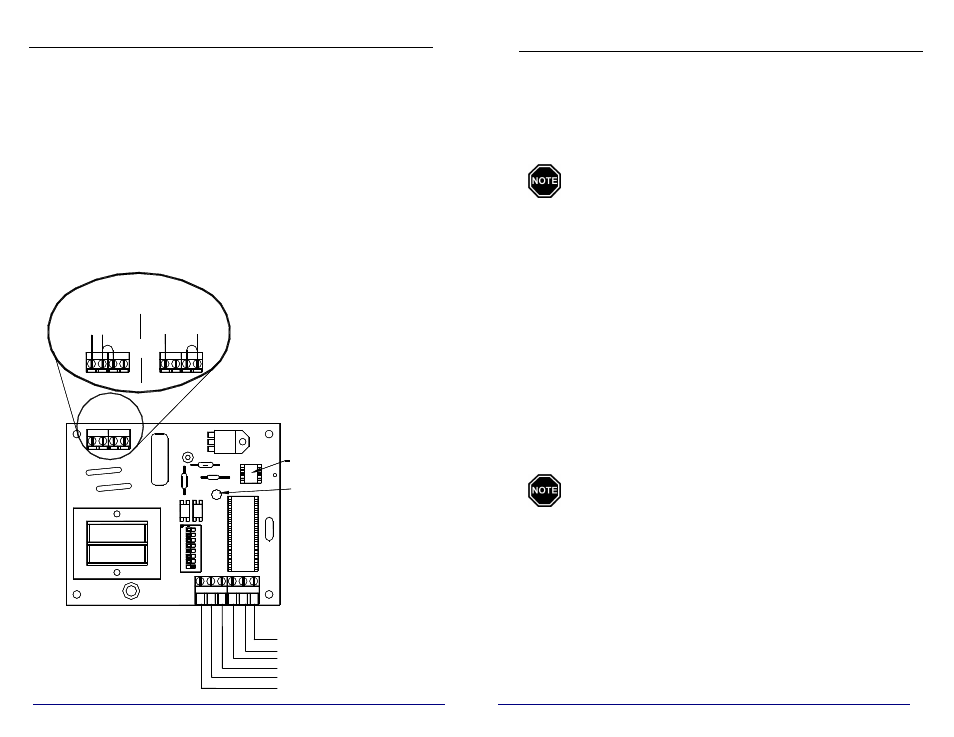

If the transmitter is to be connected to 120V, transformer tapping

MUST be changed. To change transformer tapping to 120V, move the

black wire jumper to positions P2 and 110 in the line voltage terminal

strip. Move the factory installed line voltage connections to the 110 and

L1 positions in the line voltage connections terminal strip. (See Circuit

Board Configuration below for reference to proper placement of the

jumper and wires.)

Peak Control

Connect the peak control signaling device to the "R" and "P" terminals

on the low voltage terminal strip.

Circuit Board Configuration

INSTALLER’S FINAL CHECK OUT PROCEDURE

____ 1.

Prior to energizing the electrical circuit feeding the transmitter,

inspect all field installed electrical connections to ensure they are

tight and all wires are routed correctly. All line voltage wiring

connections must be made within and routed through the line

voltage raceway of the factory-installed junction box. To ensure

proper communication, the transmitter must be grounded.

The transmitter is factory configured for 208V/240V field

connections. If using 120V input, transformer tapping must

be changed. (Refer to the Circuit Board Configuration

Diagram.)

____ 2. Make sure

the dip switch settings on the transmitter are in the

correct positions for the application. Remember, the desired PLC

channel MUST be selected for communication to occur.

____ 3.

Activate the utility peak control device and energize the

transmitter. Verify that the indicator light on the transmitter is

illuminated and corresponds with the utility peak signal (flashing

for off-peak or continuous illumination for on-peak).

____ 4.

Invert dip switch #1 on the transmitter. If the indicator light was

flashing in Step 3, it should now illuminate continuously. If the

light had been illuminated, it should now begin to flash. Return

dip switch #1 to the proper position for the application.

____ 5.

Use the guidelines which follow to verify the transmitter is

communicating with all receivers in the application

(microprocessor based heaters and Steffes mini receiver

configurations).

Communication between the transmitter and receiver

occurs on a continuous basis. Upon energizing a system,

there will be some delay in a receiver’s response to the

transmitter's signal. It takes approximately seven (7)

minutes to establish initial communication. Subsequent

communication will occur more rapidly.

INTERFACING THE TRANSMITTER WITH THE STEFFES MINI

RECEIVER (single, double or six pole configurations):

Once the mini receiver is receiving complete information from the

transmitter, the red indicator light on the mini receiver will illuminate

continuously. Refer to the Operation and Installation Guide for the Mini

Receiver to perform the checkout procedure for this device and ensure

correct installation and operation.

2

7

SO

FT

W

A

R

E

R

O

C

K

E

R

D

O

W

N

5

6

7

8

O

N

1

2

3

4

TRANSFORMER

M

IC

R

O

PR

O

C

E

SS

O

R

CHIP

MEMORY

L2

L1 L2

L1

OR

P2

22

0

11

0

L

1

LINE

VOLTAGE CONNECTIONS

120V

208V/240V

INDICATOR

LIGHT

OS - OUTDOOR SENSOR

A - ANTICIPATED PEAK

P - PEAK CONTROL

R - LOW VOLTAGE HOT

E - ROOM TEMP. SET BACK

OS - OUTDOOR SENSOR

Low Voltage

Terminal Strip Connections