3 operation, 1 typical operation, Chapter 3 operation – Dillon Quick-Check Wire Tension Meter (Old) User Manual

Page 11: Typical operation

Quick-Check User Instructions

11

3 Operation

Typical operation of the Quick-Check is covered below, followed by explanations of the

various display modes, how to change wire size, how to change the unit of measure,

etc.

3.1 Typical Operation

To perform a typical tension measurement, see the note below and follow these steps:

Take readings at three different places along the cable, moving the tension meter at

least four inches for each reading. Take the average of the readings. The built-in

average function is ideal for this task.

The handle quick release pin should be used when the Quick-Check is attached to a

cable that will be de-tensioned and re-tensioned. The pin prevents the handle from

opening once the tension falls to a small level. The pin should also be used if the

Quick-Check will be installed for a prolonged period.

1.

Turn the unit on by pressing the ON/OFF key…

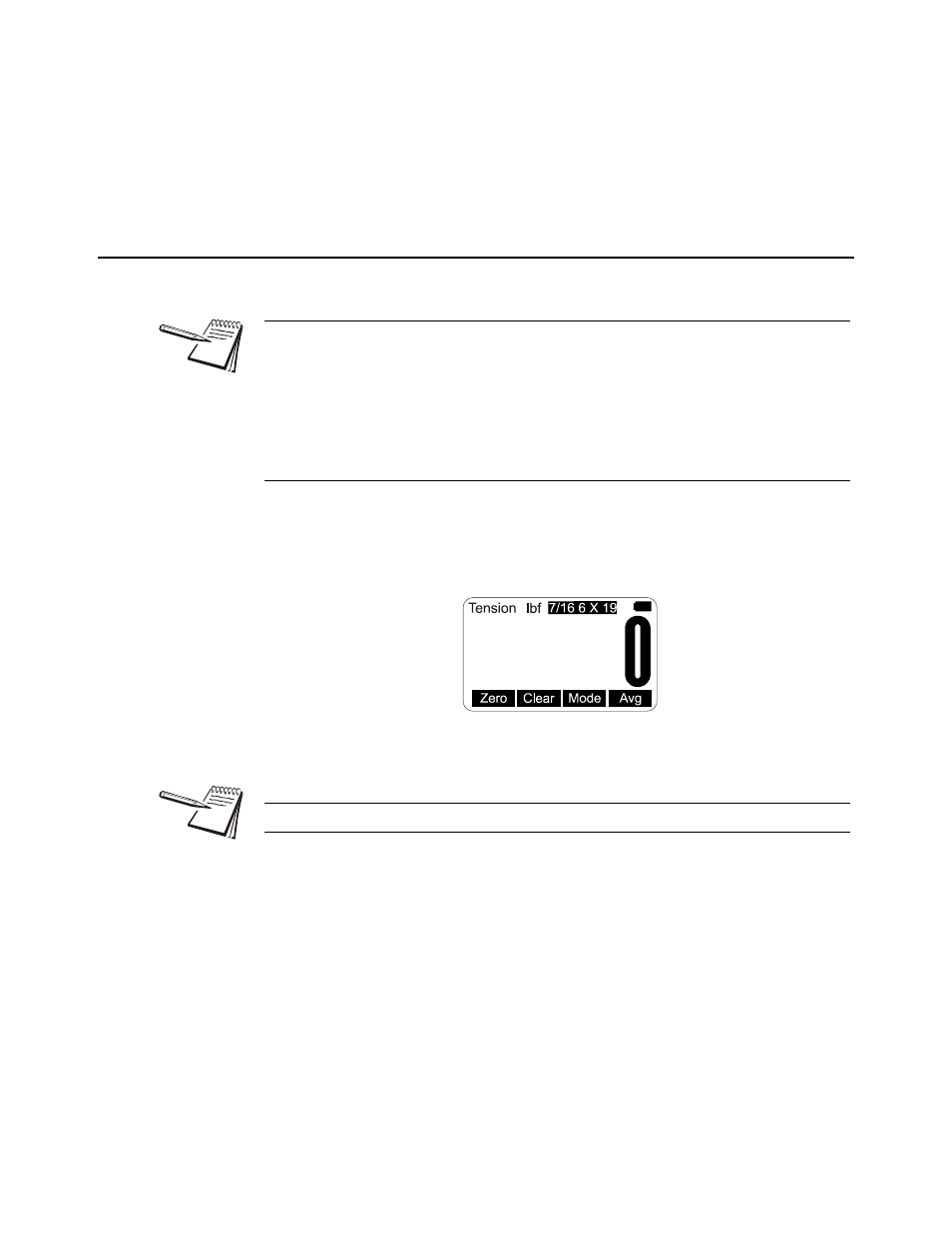

The display shows DILLON briefly, then, in this example, the screen

shows the following:

Figure 3.1 Sample display

Press the WIRE key to list the stored calibrations.

2.

This example shows the wire is a 7/16”, 6X19 stranded cable and the unit of

measure is lbf. Place the Quick-Check so the two outside sheaves hang on the

wire. Insure that the wire rope is riding in the groove of all three sheaves. See

Figure

. Press the Zero softkey to zero the display.

0 should be displayed.

3.

Raise the lever arm until it locks in the upright position to apply tension to the

wire. Read the line tension on the display.