Beckett CG10 User Manual

Page 6

6

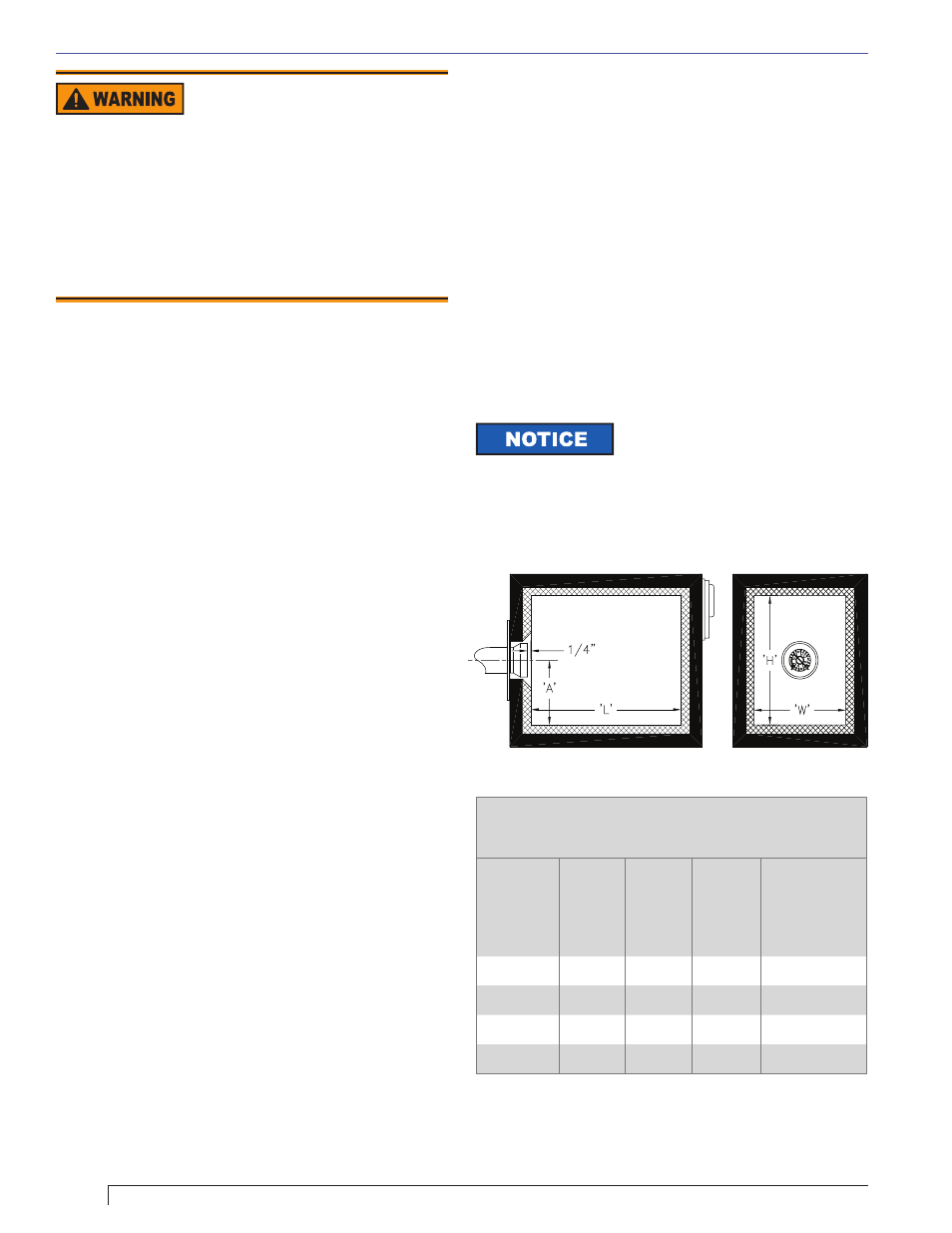

Flange mounting arrangement (Includes high-

temperature gasket and /or fi ber rope for pressure

fi ring).

Verify fi ring input range

Refer to appliance manufacturer’s instructions (if

available) for the fi ring input range. Otherwise the

maximum recommended fi ring range for the burner

depends on the length and width of the fi ring chamber

and the distance from the burner center to the chamber

fl oor. Verify that the chamber dimensions are at least as

large as the minimum values given in Figure 2. If the

appliance dimensions are smaller, reduce the fi ring rate

accordingly.

○

Minimum Combustion

Chamber Dimensions (inches)

Input

Firing

Rate in

MBH

Length

‘L’

Width

‘W’

Height

‘H’

Burner Head

Centerline to

fl oor ‘A’

300-400

18

12

12

6

400-600

22

14

14

7

600-900

26

16

16

8

900-1200

30

18

18

9

Figure 2. Minimum Combustion Chamber Dimensions

Clearances

With the burner installed in the appliance, there must

be adequate space in front of and on the sides of the

burner to allow access and operation. Verify that the

clearance dimensions comply with local codes and with

the appliance manufacturer’s recommendations.

Fuel gas supply

Verify that the gas supply piping complies with all

applicable local codes and the latest edition of the

National Fuel Gas Code ANSI Z223.1 (NFPA 54).

Insure that the supply gas pipe size is capable of

providing at least the minimum pressure required to the

burner gas train inlet at the burner’s full capacity rating.

Refer to Table 1.

Flue vent system

The fl ue gas vent system must be in good condition

and must comply with National Fuel Gas Code ANSI

Z223.1 (NFPA 54) and all other applicable codes having

jurisdiction for vent construction, capacity, and sizing.

Electrical supply

Check the nameplate on the burner to verify that the

power connections available are correct for the burner.

Refer to Figure 1. All power must be supplied through

fused disconnect switches and comply with the latest

edition of National Electric Code NFPA 70 (Canada CSA

C22.1) and all other local or applicable codes.

Verify burner components

Burner model can be checked from burner carton or

rating label on burner.

○

Test For Gas Pipe Leaks

Leaking gas could result in asphyxiation, explosion,

or fi re hazard.

The gas supply piping must be absolutely leak-free.

Pressure test the gas piping with air that is at least

three times greater than the gas pressure being

used.

Verify that there are no leaks before proceeding.

y

y

y

Section: Pre-installation Checklist

Dimensions shown are for cast

iron sectional boilers with uptakes

between sections. For minimum dimensions of other

furnace types consult R.W. Beckett Corporation.