Prepare the burner – Beckett NX User Manual

Page 8

8

Combustion chamber — Burner retrofi tting

Verify that the appliance combustion chamber

provides at least the minimum dimensions given in

Table 3.

○

Chamber Dimensions (inches)

Firing Rate

(GPH)

Round

I.D.

Rectangular

Height Floor to

nozzle

Width

Length

0.50

8

7

8

12.0

5-6

0.75

9

8

9

12.0

5-6

1.00

10

9

10

12.5

5-6

1.25

11

10

11

12.5

5-6

1.50

12

11

12

13.0

6-7

1.75

14

12

15

13.5

6-7

Table 3. Chamber Dimensions

Prepare the Burner

General

In most cases, the burner is ready to mount to the

appliance. There can be situations where the burner

needs to be reconfi gured to perform properly in the

appliance. Review the appliance manufacturer’s

specifi cations prior to installing to determine if any

modifi cation is required to properly confi gure the burner.

Instruction on how to perform the following burner

preparation tasks can be found in the Professional

Maintenance section.

Remove / install burner nozzle

Check head / air adjusting plate

Low Firing Rate Baffl e (If specifi ed)

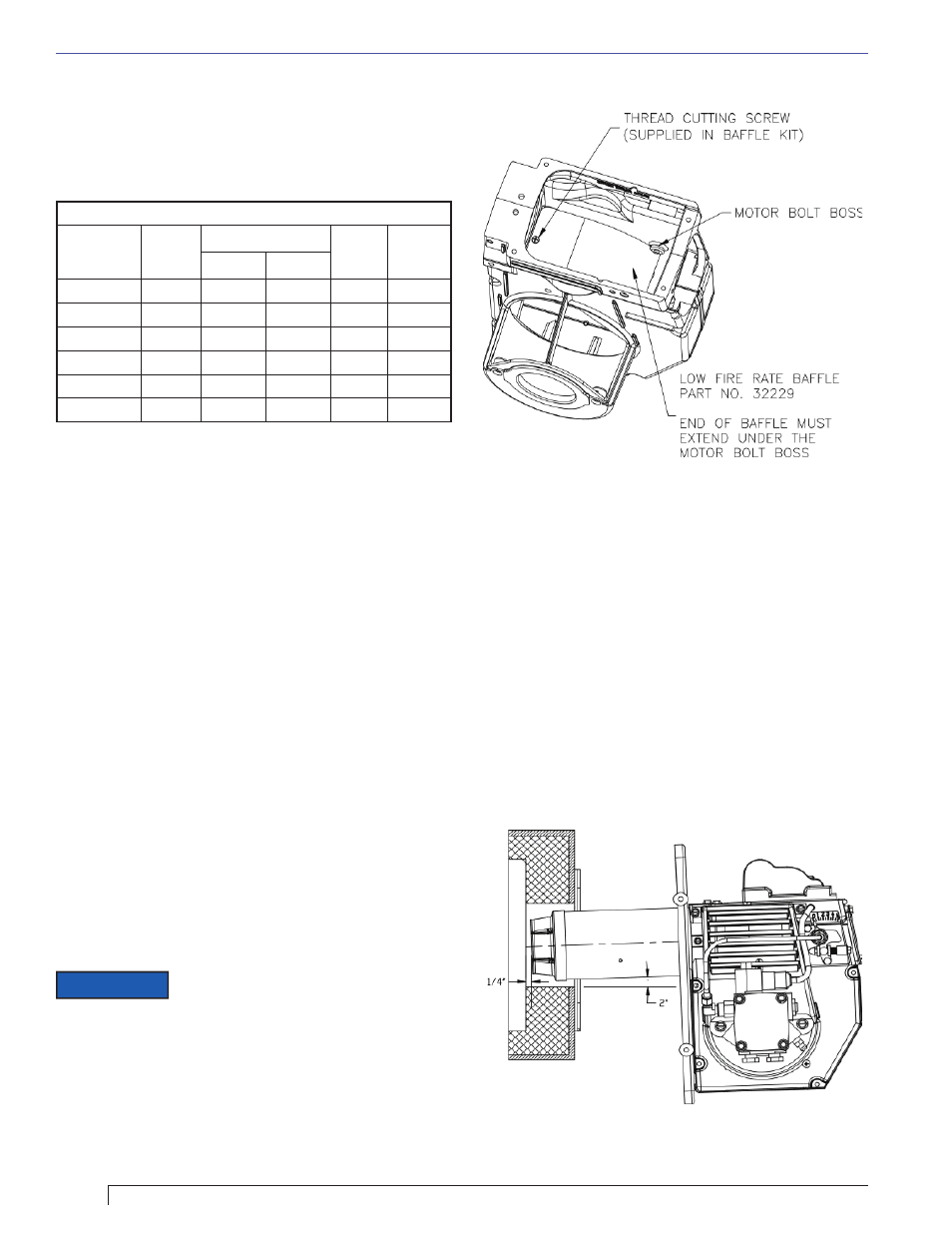

The NX Low Firing Rate Baffl e (LFRB), refer to Figure

3, reduces the burner airfl ow and pressure. Refer to the

appliance manufacturer’s instructions or the Beckett

OEM Specifi cation Guide part number 6711. To avoid

poor burner performance, do not omit the baffl e when

specifi ed or install the baffl e when not specifi ed.

○

○

Mount Burner on Appliance

Verify that the air tube installed on the burner provides

the correct insertion depth. Refer to Figure 4.

The end of the air tube should normally be 1/4” back

from the inside wall of the combustion chamber. Never

allow the leading edge of the retention ring to extend

into the chamber, unless otherwise specifi ed by the

appliance manufacturer.

Bolt the burner to the appliance using the fl ange that is

provided.

The Low Firing Rate Baffl e may

have been factory installed. If fi eld

installation is required, insert the Low Fire Rate Baffl e

into the housing, aligning the mounting screw hole with

the notched hole in the burner housing. Make note that

the curved end of the baffl e should be below the motor

bolt boss. Tighten the thread cutting screw to 12-24 in-lbs.

NOTICE

Figure 4. – Mounting Burner in Appliance

SK9668

Figure 3. – Mounting Low Fire Rate Baffl e in burner

housing.

SK9698

Section: Prepare the Burner