Beckett NX User Manual

Page 20

20

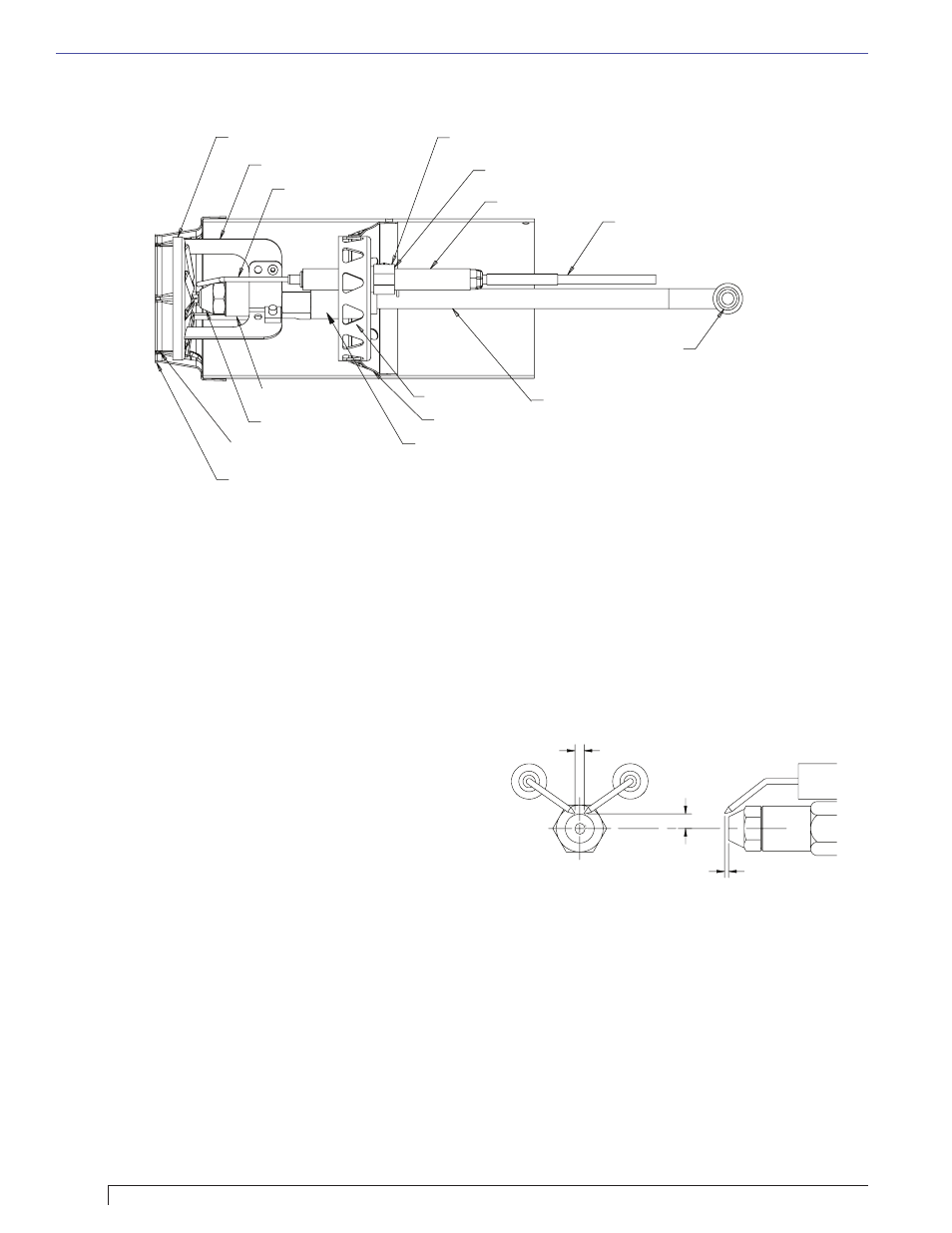

Figure 11. – Nozzle Line/Head/Air Tube Assembly (Low fi ring rate shown.)

Retention Head

Retention Head

Head Support Legs

Head Support Legs

Electrode Tips

Electrode Tips

Electrode Clamp

Electrode Clamp

Electrode Bracket

Electrode Bracket

Electrode Insulator

Electrode Insulator

Electrode Extension Rods

Electrode Extension Rods

Nozzle Adapter

Nozzle Adapter

Nozzle

Nozzle

Stops in Retention Ring

Stops in Retention Ring

Retention Ring

Retention Ring

Throttle Ring

Throttle Ring

Throttle Cup

Throttle Cup

Nozzle Line

Nozzle Line

Bulkhead Fitting

Bulkhead Fitting

SK9666A

SK9666A

Throttle Cup Hub

Throttle Cup Hub

Use a 5/8” open-end wrench to carefully remove the

existing nozzle.

Inspect the nozzle adapter before installing the

new nozzle. If it is grooved or scratched on the

sealing surface, replace the nozzle line assembly.

If the surface is damaged, oil could leak at the

nozzle to adapter joint, causing serious combustion

problems.

Protect the nozzle orifi ce and strainer when

installing. If the orifi ce gets dirt in it or is scratched,

the nozzle will not function properly.

To install a new nozzle, place a 3/4” open-end

wrench on the nozzle adapter. Insert the nozzle

into the adapter and secure fi nger tight. Finish

tightening with a 5/8” open-end wrench. Use care

to avoid bending the burner head support legs or

electrodes.

Do not over-torque the nozzle when installing. This

will cause deep grooves in the nozzle adapter,

preventing a seal when a new nozzle is installed.

Carefully check and realign the electrode tips after

replacing a nozzle, ensuring the electrode settings

comply with Figure 12.

If the head was removed when replacing the

nozzle, carefully reconnect the head to the nozzle

adapter. Make sure to align the key in the support

leg with the keyway in the nozzle adapter and

to butt the head support to the nozzle adapter

shoulder, see Figure 13.

4.

5.

6.

7.

8.

9.

10.

Check/Adjust Electrodes

Check the electrode tip settings, as shown in Figure

12. If necessary, adjust by loosening the electrode

clamp screw (Figure 11) and slide/rotate the

electrodes as necessary. When the adjustment is

complete, securely tighten the clamp screw.

Note that if the throttle cup is moved be sure to

reposition it with no gap between the nozzle adapter

and hub.

○

○

Section: Perform Regular Maintenance

Check Retention Head Alignment and Cad

Cell Sighting

(Refer to Figure 13.)

The cad cell sighting holes in the throttle cup and

the retention head must be aligned to allow the cad

cell to detect the fl ame. Make sure the stamped key

in the retention head collar lines up with the keyway

in the nozzle adapter when mounting the retention

head. Note that in specifi c applications, the retention

head may not have a sighting hole.

○

Figure 12 - Electrode tip gap and spacing

5/32 GAP

1/4 above

nozzle center

1/8 Nozzle-to-tip

Spacing

5/32” Gap

1/4” Above

nozzle center

3/32” Nozzle-to-tip

spacing