Start the burner and set combustion – Beckett NX User Manual

Page 15

15

NX Burner Manual

Pointer

Zero Setting

Locking Nut

Adjustment

Screw

Am52000

Section: Start the Burner and Set Combustion

Start the Burner and Set

Combustion

Start-up and Initial Settings

in the fl ue pipe between the appliance and the

barometric draft regulator. Seal this hole when

testing is complete. (See appliance manufacturer’s

instructions for location.)

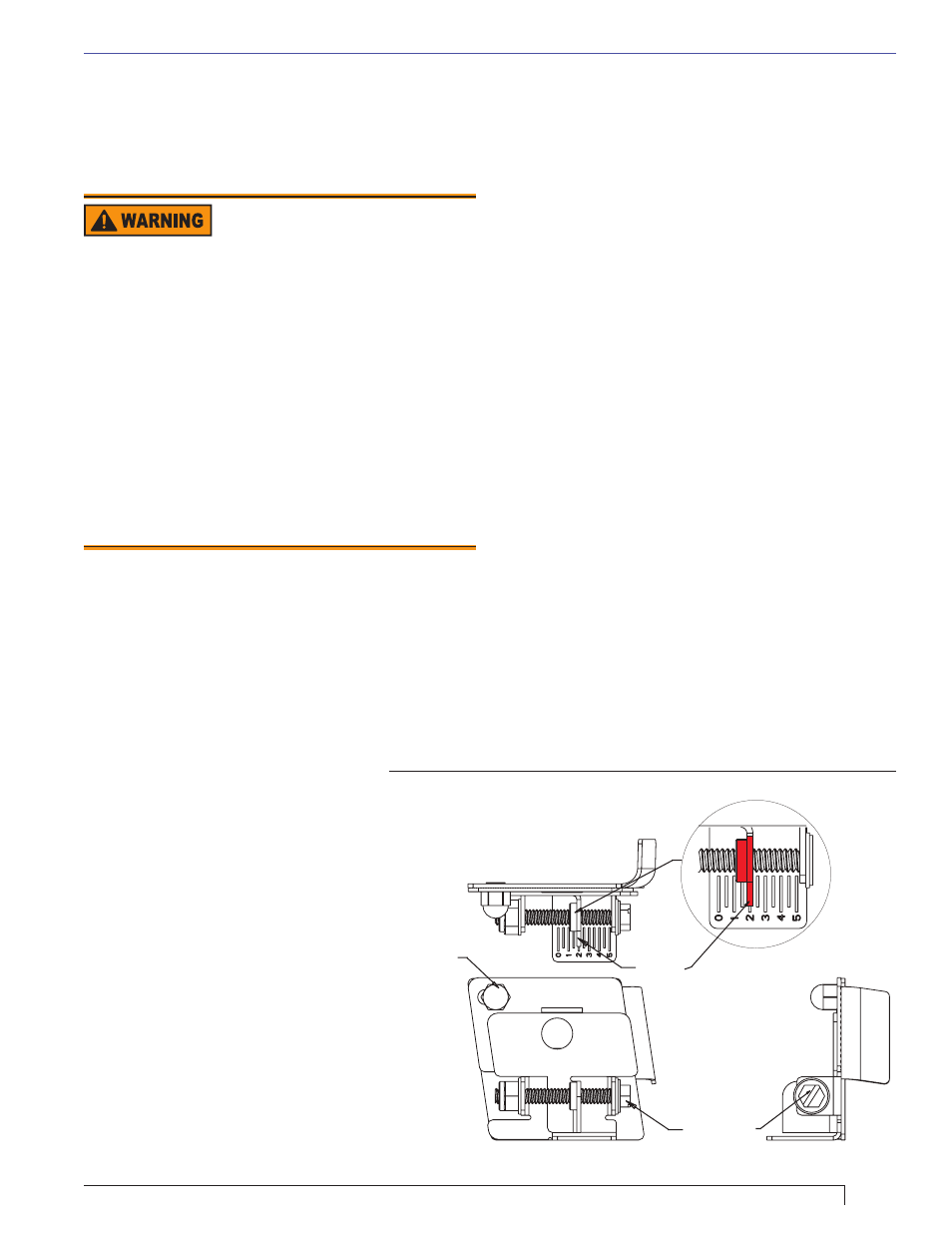

Check/Adjust Zero Calibration Head/Air

Adjustment Mechanism. Refer to Figure 10.

The rear service door must remain closed for

this proceedure.

Loosen the splined nut approximately one turn.

A 5/16” nut driver or fl at blade screwdriver can

be used to turn the adjustment screw for head/

air setting.

Slightly loosen the zero setting acorn nut.

Turn the screw until the reading is set to zero.

(Mid-point of pointer should line up with zero.

Turn the air adjustment screw counterclockwise

to adjust the plate with the pointer to the zero

position.

Slide the nozzle line assembly forward until the

retention head engages the fi xed stops in the

retention ring at the end of the air tube.

Tighten the zero setting acorn nut.

The adjustment screw may now be turned

clockwise to adjust the head/air setting.

Turn the adjusting screw to a setting 1/2 number

lower than the proper setpoint as indicated

in Tables 7a and 7b. Then turn the adjusting

screw counterclockwise to the proper setting.

Tighten the splined nut after the head/air setting

has been adjusted.

7.

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

Do not allow oil to spray into a hot combustion

chamber while bleeding air from the pump.

Install a gauge in the nozzle discharge port tubing

or fully open the pump bleed valve to prevent oil

spray from accumulating in the combustion chamber

during the air bleed procedure.

Ensure that all bubbles and froth are purged from

the oil supply system before tightening the pump

bleed valve.

Ensure that the appliance is free of oil and oil vapor

before starting or resetting the burner.

y

y

y

y

Failure to prime the pump properly could result in

unstable combustion, hot gas puff-back and heavy

smoke.

Hot Gas Puff-Back and

Heavy Smoke Hazard

Figure 10. – Head/air Adjustment Plate Assy.

Open the shutoff valves in the oil supply line to the

burner.

Referencing Figure 10, verify and/or set the

Head/Air Adjustment Pointer to the value specifi ed

by the Appliance Manufacturer. If the Appliance

Manufacturer’s values are not available, refer to

Table 7a or 7b. (This is an initial air setting for

the pump bleeding procedure only.) Calibrated

test instruments must be used for the fi nal head/air

adjustment.

Adjust the thermostat or

temperature controller to call for

heat. (Note: return controller(s)

to the original settings upon

completion of burner installation

or service.)

Close the line voltage switch to

start the burner. If the burner

does not start within the 3 to 10

second safety start check timing,

you may have to reset the safety

switch on the burner primary

control.

Bleed the air from the fuel pump

as soon as the burner motor

begins rotating.

Prepare for combustion tests

by drilling a 1/4” sampling hole

1.

2.

3.

4.

5.

6.