Vermont castings ewf30, Ceiling chimney hole/ possible obstructions, Cutting the hole – Vermont Casting EWF30 User Manual

Page 10: Framing the ceiling hole, Positioning, safety strips, securing the fireplace, Chimney hole size

10

Vermont Castings EWF30

20008662

Locate center point of the chimney on ceiling as though

a straight up chimney arrangement is to be used. Mea-

sure your offset dimension from straight up chimney

center point on ceiling.

Ceiling Chimney Hole/

Possible Obstructions

The size of the hole in ceiling will vary with the angle at

which the chimney passes through ceiling.

Drive a nail up through ceiling at marked chimney

center point. Go to floor above and see where hole

will be cut. Check to see where existing ceiling joists

and other possible obstructions are located...i.e. wiring,

plumbing etc... If necessary, re-position chimney and/or

fireplace to avoid obstructions.

Cutting the Hole

Cover fireplace collar opening and cut proper sized

chimney hole in chimney.

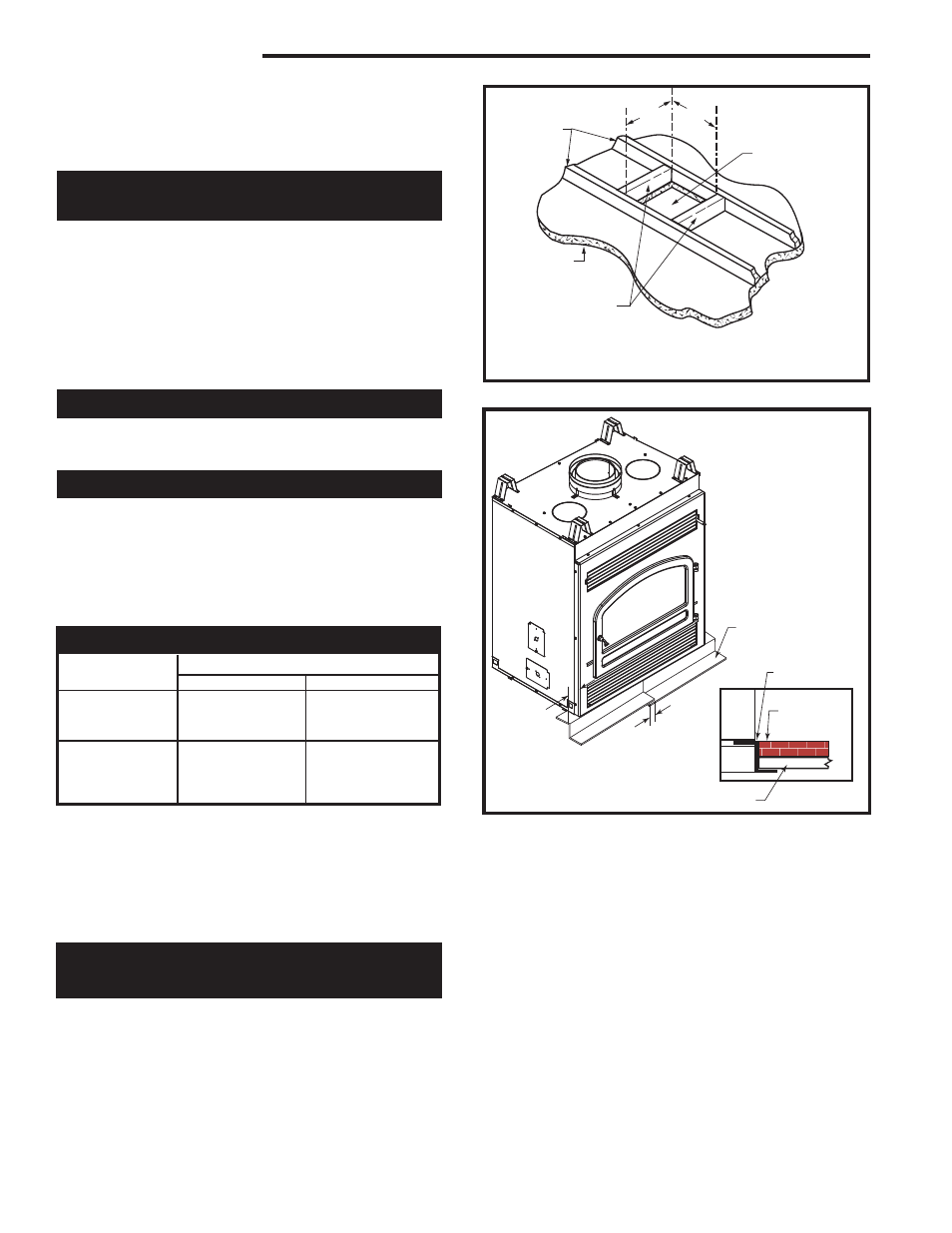

Framing the Ceiling Hole

Frame the ceiling chimney hole as shown in Figure

10. It is good practice to use framing lumber that is the

same size as the ceiling joists; this is a requirement at

attic level.

The following table gives firestop spacer model num-

bers:

FP551

BR/BC

9/29/97

AB

AB

A "SK" Series framing = 14���" X 14���" (368 x 368 mm)

B "S" Series framing = 17���" X 17���" (445 x 445 mm)

Existing

Ceiling

Joists

Chimney

Hole

Ceiling

New Framing

Members

FP551b

Fig. 10 Typical frame for ceiling chimney hole.

The inside dimension of the frame must be the same

as the hole size selected from Figure 9 in order to pro-

vide required the 1¹⁄₂” (38 mm) air space between the

outside diameter of the chimney and the edges of the

framed ceiling hole.

Positioning, Safety Strips,

Securing the Fireplace

Slide fireplace into position.

Safety strips are used to ensure that any combustible

materials in front of the fireplace are protected even

though a noncombustible hearth extension is required.

When the finished extended hearth is added, the top

of the finished hearth must be flush with the bottom of

the fireplace. “Z” shaped metal safety strips have been

supplied with the fireplace and are required for instal-

lation. The safety strips provided have a 1” offset. For

applications with a greater offset, “Z” shaped strips will

have to be fabricated of metal. Overlap safety strips at

least 1/2” to provide a positive joint. The safety strips

must also extend at least 1¹⁄₂” (38mm) beyond the sides

of the fireplace. (Fig. 11)

NOTE: Safety strips are not required over noncombus-

tible floors where all supports at the base of the fire-

place are noncombustible.

Four (4) nailing flanges are supplied with the fireplace

(found on the fireplace hearth). To level the box and

secure it firmly in place, remove the nailing flanges from

the hearth and install at the sides of the fireplace as

shown in Figure 12.

FP1564

Install metal

safety strips

3/05

“Z” Metal Safety

Strips (1 or 2 pcs.)

“Z” Safety Strip

Hearth Ext.

Fire-

place

Plat-

form

FP1564

1¹⁄₂”

(38mm)

1/2” Min.

Overlap

Fig. 11 Safety strip installation.

Decorative

Hearth

Face

Fig. 9 Ceiling chimney hole sizes necessary for installing

firestop spacer.

Chimney Hole Size

Size of Chimney

Vertical

30°

8" Flue

SKFS2A

SKFS6A

"SK" Series

14¹⁄₂" x 14¹⁄₂"

14¹⁄₂" x 25¹⁄₂"

(368mm x 368mm) (368mm x 648mm)

8" Flue

FS2A

FS6A

"S" Series 3-Wall

17¹⁄₂" x 17¹⁄₂"

17⁷⁄₈" x 29⁵⁄₈"

(445mm x 445mm) (454mm x 753mm)

Angle of Chimney at Ceiling