Nexen 5H20P-E 911317 User Manual

Page 5

2

FORM NO. L-20210-B-1209

INTRODUCTION

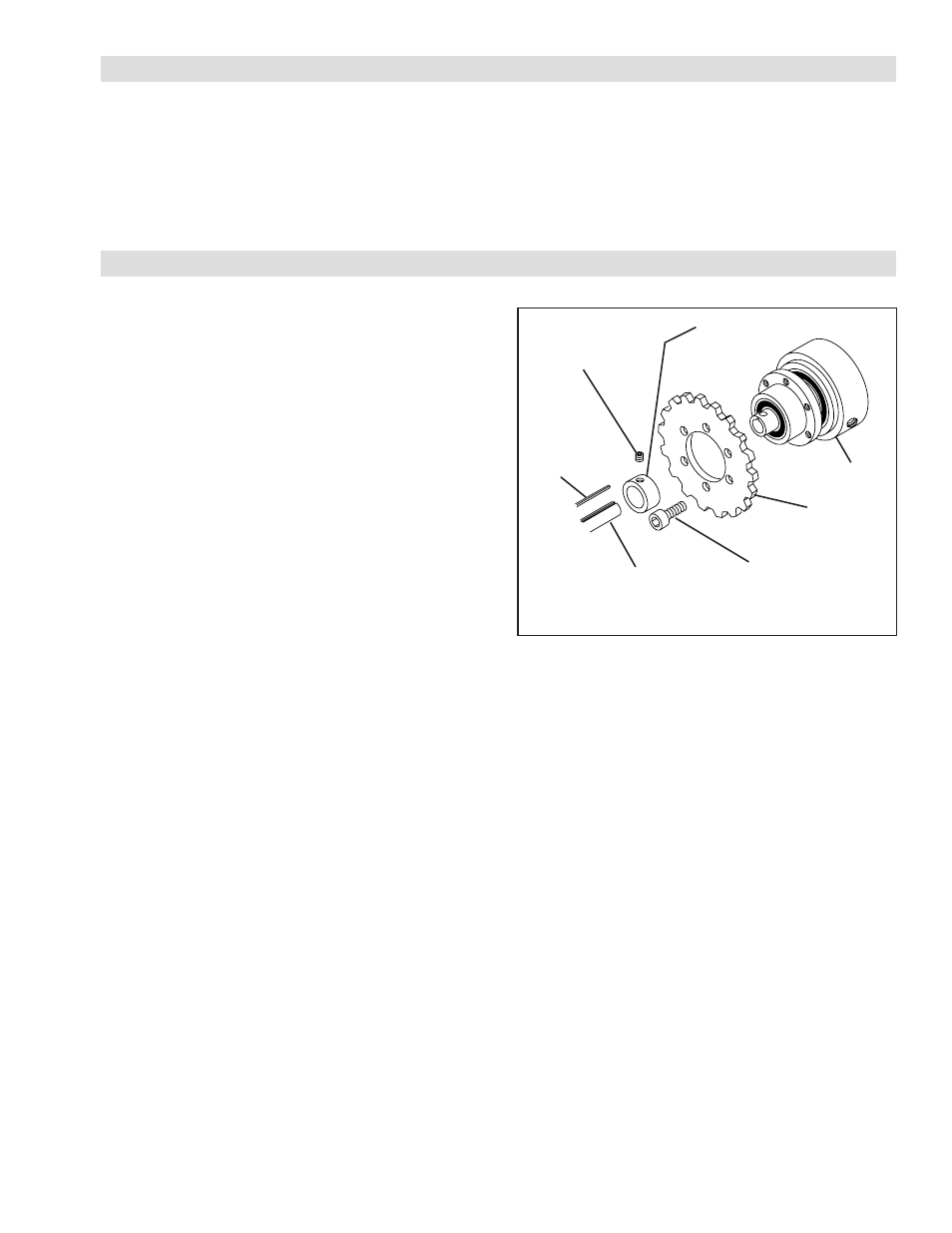

FIGURE 1

REFER TO FIGURE 1.

1. Using customer supplied 10-24 UNC 2B Socket

Head Cap Screws, secure sprocket or drive

component to Clutch.

2. Tighten the Socket Head Cap Screws to 23 ft-lbs

[31 Nm] torque.

3. Slide Hub Collar (Item 19) onto Hub of Clutch, and

align hole in Hub Collar with hole in Hub of Clutch.

4. Install customer supplied Key into shaft keyway.

5. Slide the Conveyor Clutch onto shaft.

6. Install and tighten Set Screw (Item 16) to 6 ft-lbs

[8.5 Nm] torque.

Key

(Customer

Supplied)

INSTALLATION

Nexen’s Model 5H20P Conveyor Clutches are built spe-

cifically to meet the needs of a wide range of conveyor

applications.

The Model 5H20P Conveyor Clutch operates on static

air pressure. Torque is adjusted by simply varying the air

pressure; while the Tooth Clutch design provides long life

without premature wear and slip as encountered with wrap

spring devices.

Hub Collar

(Item 19)

Machine

Shaft

Socket Head Cap Screw

(Customer Supplied)

Sprocket

5H20P

Set Screw

(Item 16)