Proper system alignment, Mounting surface details, Installation – Nexen PRD1100 966902 User Manual

Page 6

6

FORM NO. L-21274-A-0113

PROPER SYSTEM ALIGNMENT

Unlike traditional gear systems, the RPG System operates

with no mechanical clearance and requires a preload. For

optimal performance the preload must remain as constant

as possible as the ring gear travels past the pinion, or

conversely, the pinion orbits around the stationary ring gear.

To achieve this the ring gear and pinion concentricity and

axial variance and pinion axis concentricity and parallelism

to the axis of rotation must be well maintained. The

following guidelines will ensure this is achieved.

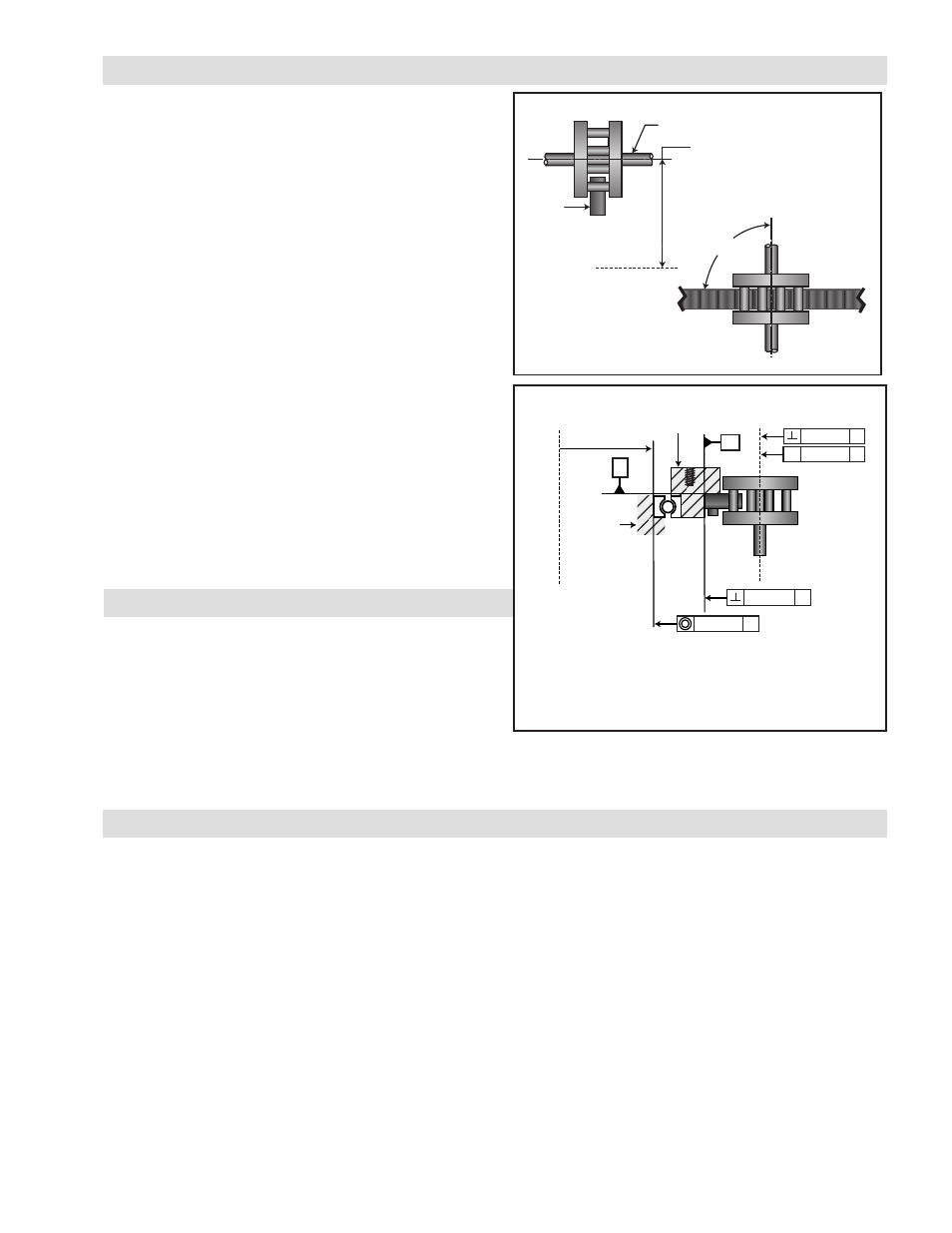

1. See Figures 1 and 2.

2. The Pinion axis of rotation must be concentric (±0.02

mm [± 0.0008 in]) to the axis of rotation of the ring

gear and the angle between the Pinion Shaft axis and

the plane the ring gear is in must be exactly 90° (Refer

to Figure 1).

3. The Pinion Shaft must be supported adequately to

ensure full contact of roller pins along the face of ring

gear teeth.

4. Once the RPG-B system is properly installed and

preloaded verify the meshing tooth pattern is correct

as outlined in the System Alignment Verification

section on Page 11.

Gear

90˚

Pinion

Shaft

Axis of

Rotation

This distance must remain

concentric within

0.02 mm [ 0.0008 in]

Figure 1

Pinion Alignment Requirements

Fixed Ring Gear

A

B

.02 mm B

.02 mm A

.02 mm B

.02 mm A

//

Rotating

Mounting

Ring

Axis of

Rotation

Support

Base

Figure 2

Possible Mounting Configurations

Tolerances Allowed In Roller Pinion Setup

Additional dimensional detail can be found in Nexen’s

product drawings.

MOUNTING SURFACE DETAILS

The surface used to mount the RPG-B should be machined

to a flatness of .050mm as shown to ensure proper

alignment. See Figure 1.

All provided provisions for fasteners should be utilized.

Make sure there is proper clearance around the gearbox

as seen in Figure 1.

INSTALLATION

S

yStem

m

ountinG

• Clean and check all mounting surfaces before

assembly. Contamination from dirt or machining burrs

can affect system performance.

• Position the system on the mounting surface. There

are threaded holes available in the bearing to use as

lift points, typically M12 x 1.75.

• To center the system, Nexen recommends using

the OD of the teeth as a reference dimension for

alignment.

• Once the system is in location, install the provided

mounting bolts. Tighten the bolts in a star pattern to

ensure even distribution of load.

D

ial

P

late

m

ountinG

(o

utPut

)

• The dial plate is designed to be piloted by a series of

dowel pins installed in the plate and that straddle the

male pilot on the ring drive. Drawings are available for

each specific size, which will aid in understanding the

method of piloting the dial plate.

• The dial plates should be mounted using all available

holes. Again, tighten in a star pattern to ensure even

load distribution. It is the responsibility of the customer

to ensure the bolt grade and quantity is sufficient for

the application.