Nexen PRD1100 966902 User Manual

Page 10

10

FORM NO. L-21274-A-0113

APPLYING PRELOAD

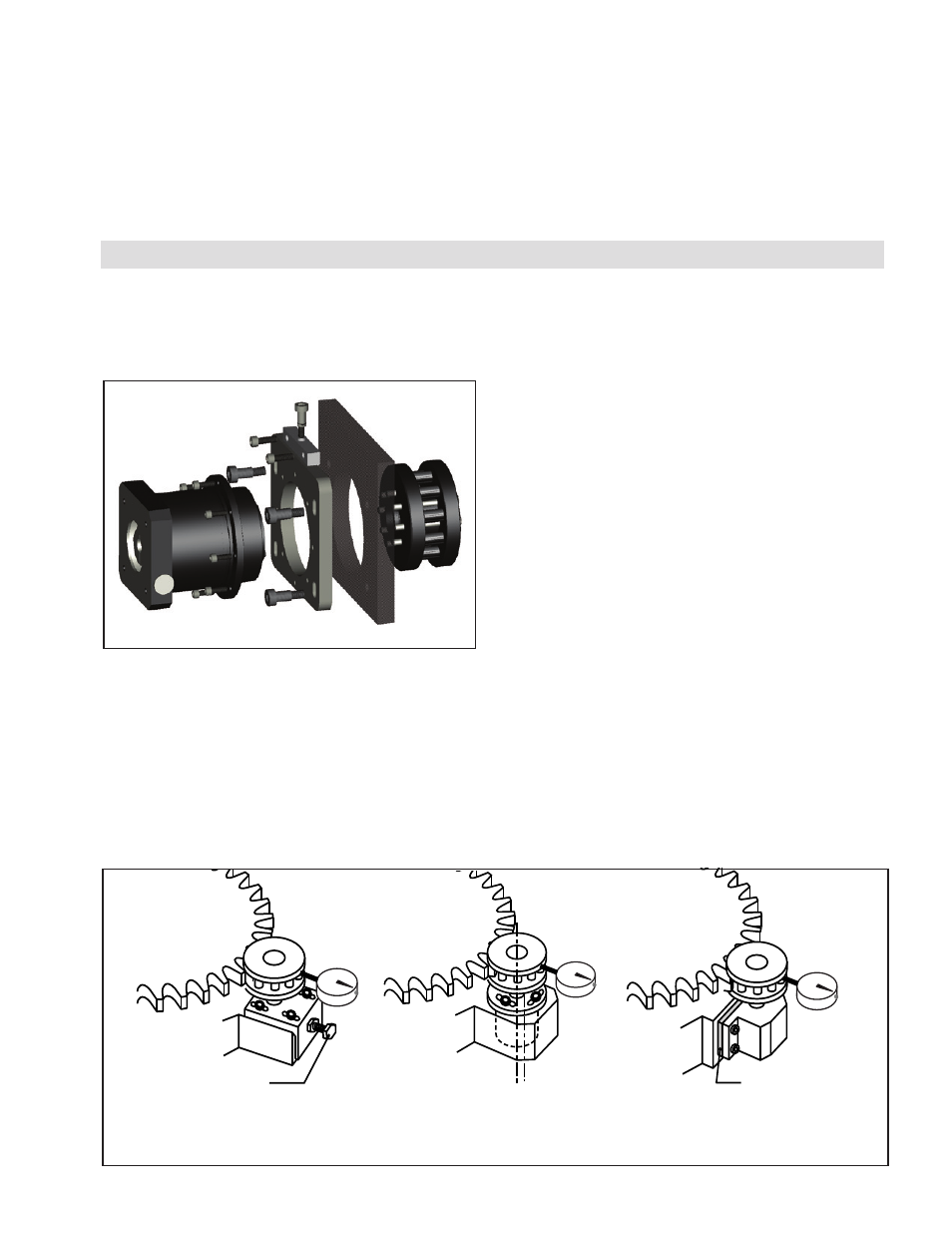

If you would prefer to not design your own pinion

preloading mechanism, Nexen offers a high precision push

bolt preloading system that bolts between the machine

frame and servo reducer to simplify machine design and

achieve optimal results. See figure 10.

Preloading Procedure

Note: Be careful engaging the pinion and servo

assembly to the gear to avoid damaging the gear

teeth or pinion rollers.

1. With a dial indicator mounted on the pinion frame,

measure off the tooth peaks. Move the axis taking

frequent measurements to locate the high spot in

the run. This is where the pinion preloading should

be done to prevent excessive preload from occurring

elsewhere in the run.

2. Apply serviceable thread locking compound to the

pinion preloader slider bolts and install the servo and

preload mechanism. Ensure the preload related bolts

are just loose enough to allow the pinion to be pulled

away from the gear teeth. For the Nexen Preloader

System, this is approximately 0.2 - 0.3 Nm [2 - 3 in-

lbs].

Nexen Precision Pinion Preloader product numbers and

more information can be found at www.nexengroup.com

on any of the RPG pinion pages under accessories in the

left hand column.

To ensure optimal meshing of the roller pins with the gear

teeth, the shaft must be preloaded to 0.010 - 0.015 mm

[0.0004 - 0.0006 in] beyond first contact with teeth.

Figure 10

NOTE: Do not apply excessive preload. Preloading

beyond 0.015 mm [0.0006 in] will decrease product

life, increase noise, and cause vibration. When the

RPG system is properly preloaded, there will be no

tangential play between the gear teeth and the pinion

rollers if the pinion is not allowed to turn and the

rotating assembly forced back and forth in the direction

of rotation.

Refer to Figure 11 for suggested preload methods.

17. Re-torque the mounting screws once more to the full-

specified torque value in Table 3 to ensure full torque

has been reached on all fasteners. Tighten in the same

order as above.

18. Repeat variance inspection Step 15 and verify the

variance listed is achieved after fully torquing the

pinion. If variance is out of specifications the pinion

should be removed inspecting for contaminates, burrs,

or surface defects that would interfere with full contact

between the adapter (if used) and gearhead flange.

Indexing the pinion relative to the adapter (if used) or

gearhead may help in some cases. Repeat the pinion

installation procedure starting with Step 13.

Push Bolt

Figure 11

Adjustment by Oblong Holes

(Preferred Method)

Adjustment by Eccentric Holes

(Option 1)

Adjustment by Shim

(Option 2)

Shim