Nexen PRD1100 966902 User Manual

Page 12

12

FORM NO. L-21274-A-0113

DISENGAGING THE ROLLER PINION

1. De-couple the load from the RPG system.

2. Disconnect the power source, ensuring that no torque

is applied to the roller pinion.

3. Remove pinion preload by loosening the preload

mechanism sliding bolts slightly and then turning the

preload application screw(s) to remove the pinion

preload. You should be able to slightly separate the

pinion from the gear teeth now.

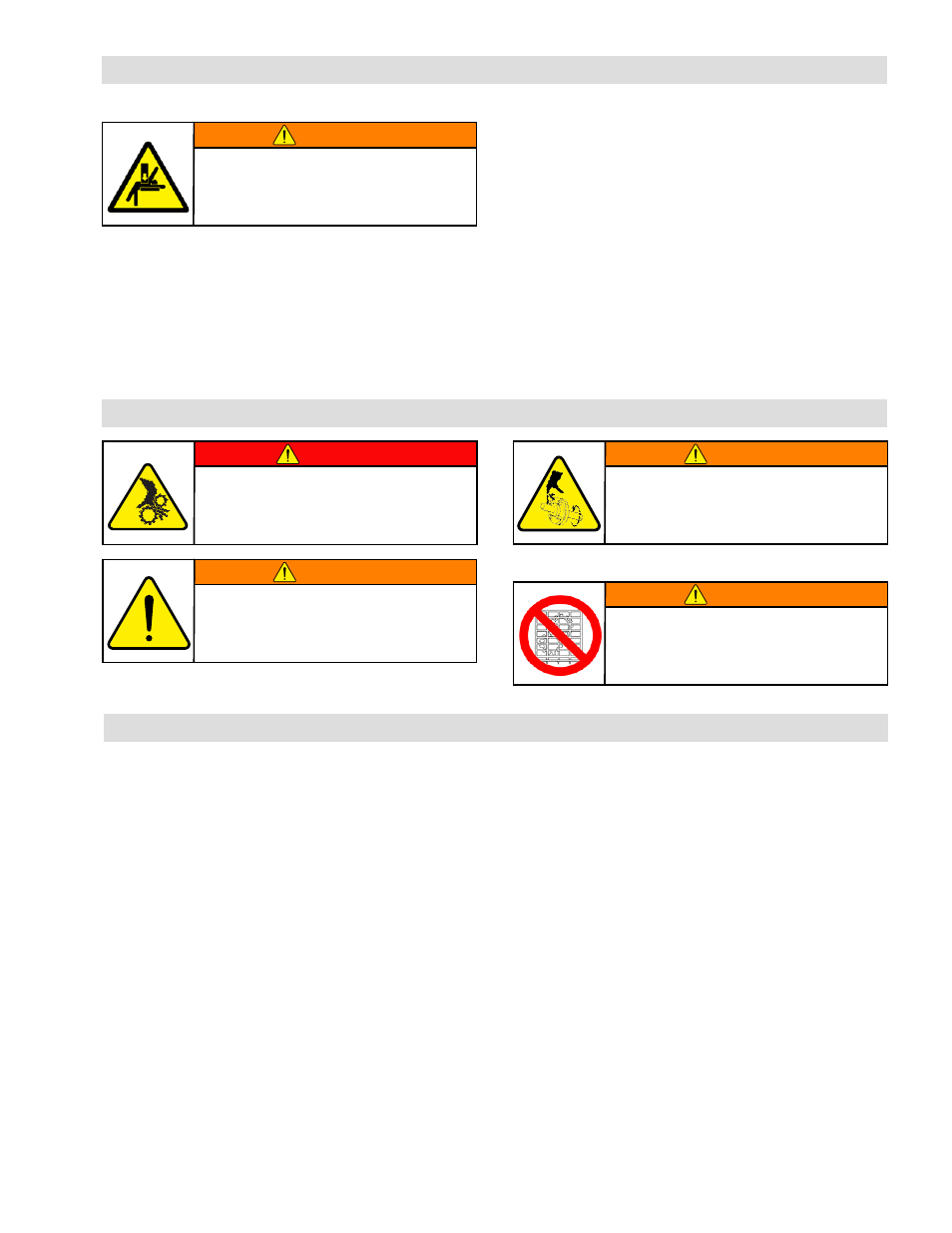

WARNING

Failure to properly support the load before

disengaging the RPG system could cause

serious harm to operators or equipment.

4. Progressively loosen non-adjacent bushing fasteners

in the same order they were tightened until all are

removed from the bushing (Refer to Figure 4).

5. Insert the bushing fasteners into the threaded holes

in the bushing flange and alternately tighten them as

illustrated in Figure 4 to release the locking action of

the bushing.

6 Lift the servo/reducer/preload mechanism assembly

from the gear or slide the servomotor/reducer out of

the pinion bore.

NOTE: Inspect all bushing fasteners and replace any that

show excessive wear. Contact Nexen for replacements.

OPERATION

DANGER

This product has moving parts that

can crush or cut appendages. Provide

adequate spacing or guarding from any

operating product.

WARNING

Never exceed maximum operating

speeds listed for your product.

WARNING

Ensure proper guarding of the product is used.

Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

WARNING

Use appropriate guarding for rotating

components. Failure to guard could

result in serious bodily injury.

•

Max speed of RPS25 Pinion = 1960 rpm.

LUBRICATION

The pinion needle bearings are sealed and lubricated for

life and cannot be serviced.

Nexen recommends lubricating the gear teeth every 2

million pinion revolutions or 6 months, but it may need to

be lubricated more frequently based on the application

conditions, and observable tooth or roller wear.

When lubricating the RPG system inspect the pinion

rollers and gear teeth for any abnormal wear patterns and

ensure the pinion rollers are not seized or have excessive

play. Wear on the edges of the gear teeth (not uniform

across the tooth face) or rings on the rollers indicate an

alignment problem which should be corrected to obtain

maximum system performance and life.

The rollers in new pinions, especially larger sizes, can

seem difficult to turn due to seal drag. This improves as

the pinion breaks in.

THK AFA grease is recommended for gear tooth

lubrication. Nexen offers this grease under product

number 853901. Greases for special applications such

as food grade, vacuum, or others are allowed if they use

a synthetic base, a polyurea thickener, and meet the

following Kinematic Viscosity Levels: CST@40C = 25;

CST@100C = 5. Contact Nexen for recommendations

on alternative greases.

The RPG system can be lubricated in two ways:

1. Apply grease to the pinion rollers and roll the pinion

back and forth 5 times over one meter circumference

of gear teeth, repeating the process until the entire

gear is lubricated.

2. Using a swab apply a very small dab of grease on the

middle of each tooth face and rotate the ring gear 5

times.

Wipe excess grease from the sides of the gear and pinion

body to prevent grease being thrown off during operation

and for general cleanliness.