Nexen BSB07 965040 User Manual

Page 5

5

FORM NO. L-21225-F-0813

INSTALLATION

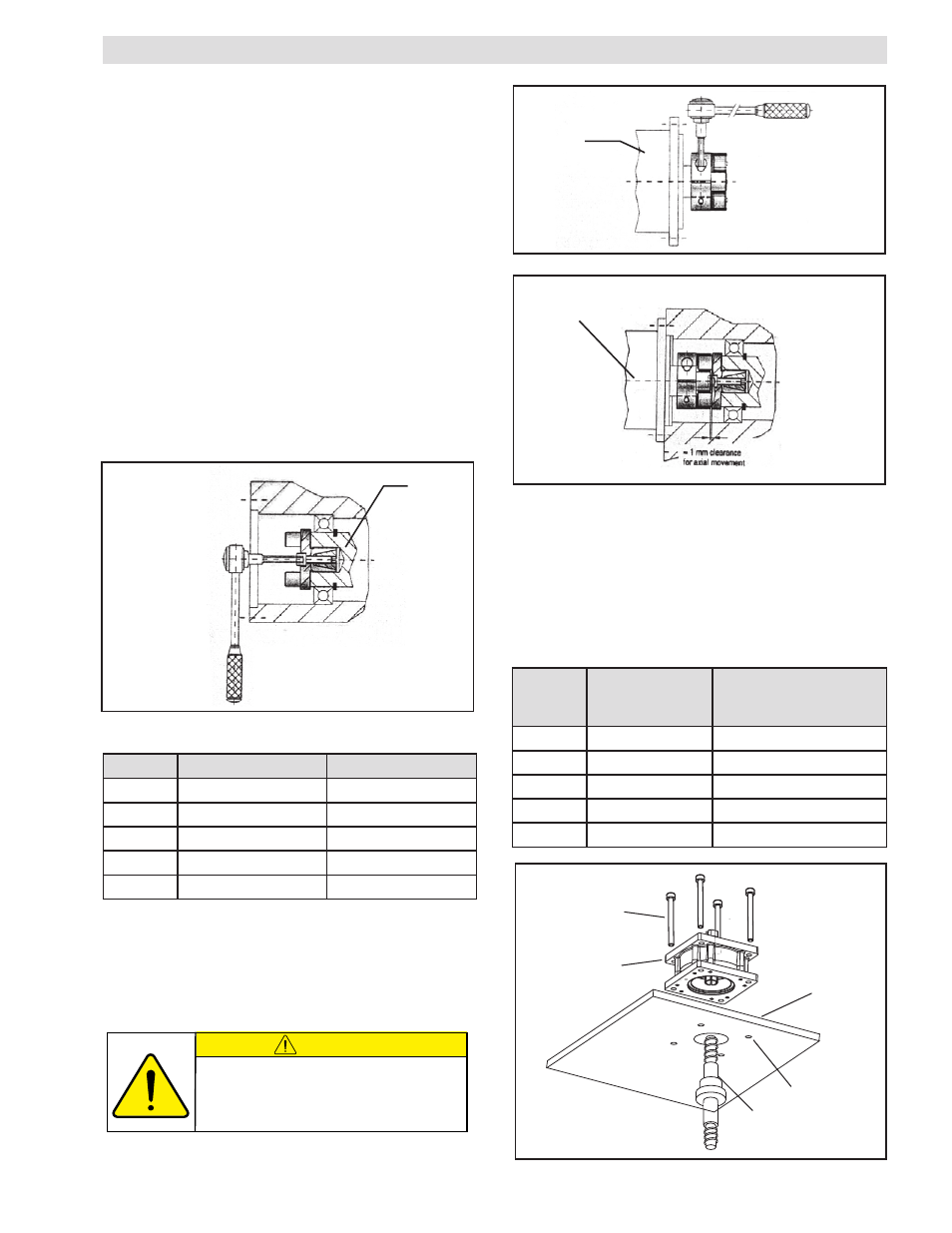

INSTALLATION ONTO A BALL SCREW

NOTE: The Ball screw Brake coupling consists of a

clamping hub and an expanding shaft side connected

together with an elastomer insert. Refer to Figures 1,

2, 3, and 4.

The two coupling hubs are concentrically machined

to accept an elastomer insert for axial misalignment.

One hub has a bore to accept the machined end of

a ball screw and a clamping hub with a radial screw.

The other side has an expanding shaft and tapered

clamping element that expands into the brake bore

when a cap screw is tightened.

1. Separate the coupling into two halves. Mount the

expansion shaft. Push the coupling shaft into the

brake bore and tighten the cap screw to the torque

specification in Table 1.

Table 1

Model

Clamp Collar

Expanding Shaft

BSB 2

2 Nm [18 in-lbs]

2.3 Nm [20 in-lbs]

BSB 3

4 Nm [36 in-lbs]

9 Nm [80 in-lbs]

BSB 4

15 Nm [133 in-lbs]

22 Nm [200 in-lbs]

BSB 5

15 Nm [133 in-lbs]

32 Nm [283 in-lbs]

BSB 7

35 Nm [310 in-lbs]

60 Nm [530 in-lbs]

2. Mount the clamping hub. Slide this coupling half onto

the machined end of the ball screw.

3. At the correct axial position, tighten the mounting

screw to the torque specification in Table 1.

Figure 3

Model

Socket Head

Cap Screw

(Customer Supplied)

Recommended

Fastening Torque

BSB 2

M5

7 Nm [63 in-lbs]

BSB 3

M6

12 Nm [107 in-lbs]

BSB 4

M8

29 Nm [260 in-lbs]

BSB 5

M10

58 Nm [520 in-lbs]

BSB 7

M12

158 Nm [1,400 in-lbs]

Ball Screw Brake

Customer Supplied

Fasteners

Base Plate

Tapped Holes

Ball Screw

Figure 4

Ball Screw

Figure 1

Brake

Shaft

Ball

Screw

Figure 2

4. Use customer-supplied screws, washer and nuts to

bolt the flanges together.

5. Apply Loctite

®

242 to the threads of the screws.

6. Torque the screws to the recommended values.

Refer to Table 2.

Table 2

CAUTION

The elastomer insert must be able to

move axially in order to compensate for

axial misalignment.