Friction facing assembly – Nexen BSB07 965040 User Manual

Page 10

10

FORM NO. L-21225-F-0813

15. Position Friction Facing (Item 8) in the Air Chamber

(Item 6) so the angled surfaces match up with the wall

of the Air Chamber and the tapered disc of the Output

Shaft (Item 1).

16. Replace the Backing Plate (Item 15), Springs (Item 9)

and Input Flange (Item 10). Note: Only BSB 7 has

Spring Backing Plate and multiple Springs.

17. Apply a drop of Loctite® 242 (blue) to the threads of

the eight Socket Head Cap Screws (Item 11).

18. Reinstall and tighten the eight Socket Head Cap

Screws (Item 11), securing the Air Chamber (Item 6) to

the Input Flange (Item 10). Alternately tighten the eight

Cap Screws to keep the input flange parallel to the

Air Chamber. Refer to Table 5 for the recommended

assembly torque.

Figure 9 BSB 7

Item 14

Item 9

Item 10

Item 11

Item 7

Item 15

Item 8

FRICTION FACING ASSEMBLY

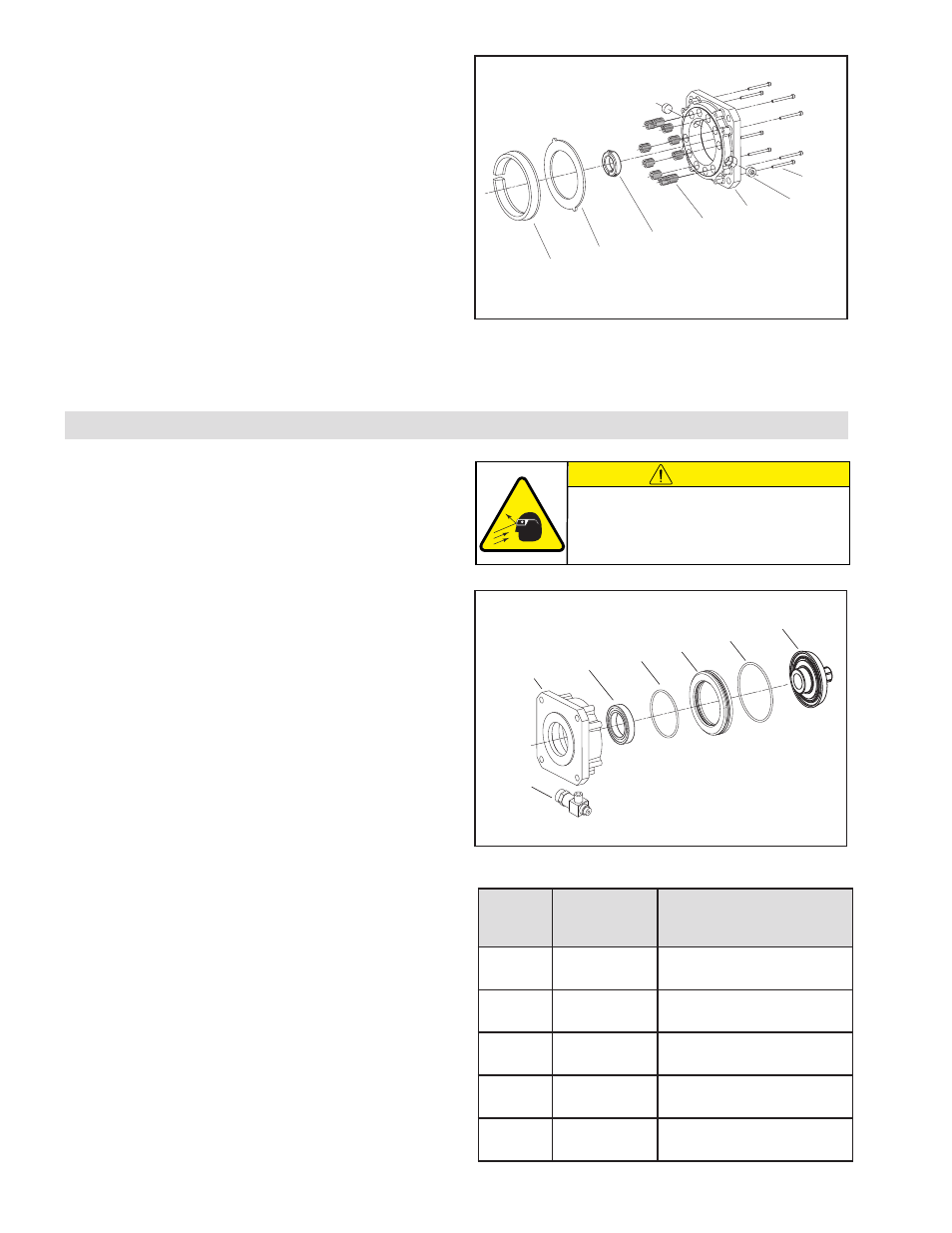

NOTE: Refer to Figure 10

1. Alternately and evenly, remove the eight Socket Head

Cap Screws (Item 11) and separate the Air Chamber

(Item 6) from the Input Flange (Item 10).

2. Remove the Input Flange (Item 10), Backing Plate

(Item 15) and ten Springs (Items 9). Note: Only BSB

7 has Spring Backing Plate and multiple Springs.

3. Remove and replace the Friction Facing (Item 8) in the

Air Chamber (Item 6). Make certain that the angled

sides mate with the wall of the Air Chamber and the

tapered disc of the Output Shaft (Item 1).

4. Replace the Backing Plate (Item 15), Springs (Item 9)

and Input Flange (Item 10). Note: Only BSB 7 has

Spring Backing Plate and multiple Springs.

5. Apply a drop of Loctite® 242 (blue) to the threads

of each of the eight Socket Head Cap Screws (Item

11).

6. Reinstall and tighten the eight Socket Head Cap

Screws (Item 11), securing the Air Chamber (Item 6)

to the Input Flange (Item 10). Alternately tighten the

eight Cap Screws so the Input Flange stays parallel

to the Air chamber Item 6) and does not pinch any

of the Springs (Item 9). Refer to Table 5 for the

recommended assembly torque.

Figure 10

Item 1

Item 2

Item 3

Item 4

Item 5

Item 6

Item 23

Table 5

Model

Socket Head

Cap Screw

(Item 11)

Recommended

Assembly Torque

BSB 2

M4

4.2 - 5.4 Nm

[37 -48 in-lbs]

BSB 3

M5

7.0 - 9.2 Nm

[62 -81 in-lbs]

BSB 4

M6

9.2 - 1.9 Nm

[81 - 105 in-lbs]

BSB 5

M8

26.2 - 34.0 Nm

[232 - 301 in-lbs]

BSB 7

M5

7.0 - 9.2 Nm

[62 -81 in-lbs]

CAUTION

Working with spring or tension loaded

fasteners and devices can cause injury.

Wear safety glasses and take the

appropriate safety precautions.