Air connections (continued) – Nexen SBP09 965110 User Manual

Page 8

FORM NO. L-21059-E-0813

8

1. Standard Configuration:

Attach the Quick Exhaust Valve (Item 23) to the brake.

Use Teflon tape and/or pipe sealant on the threads.

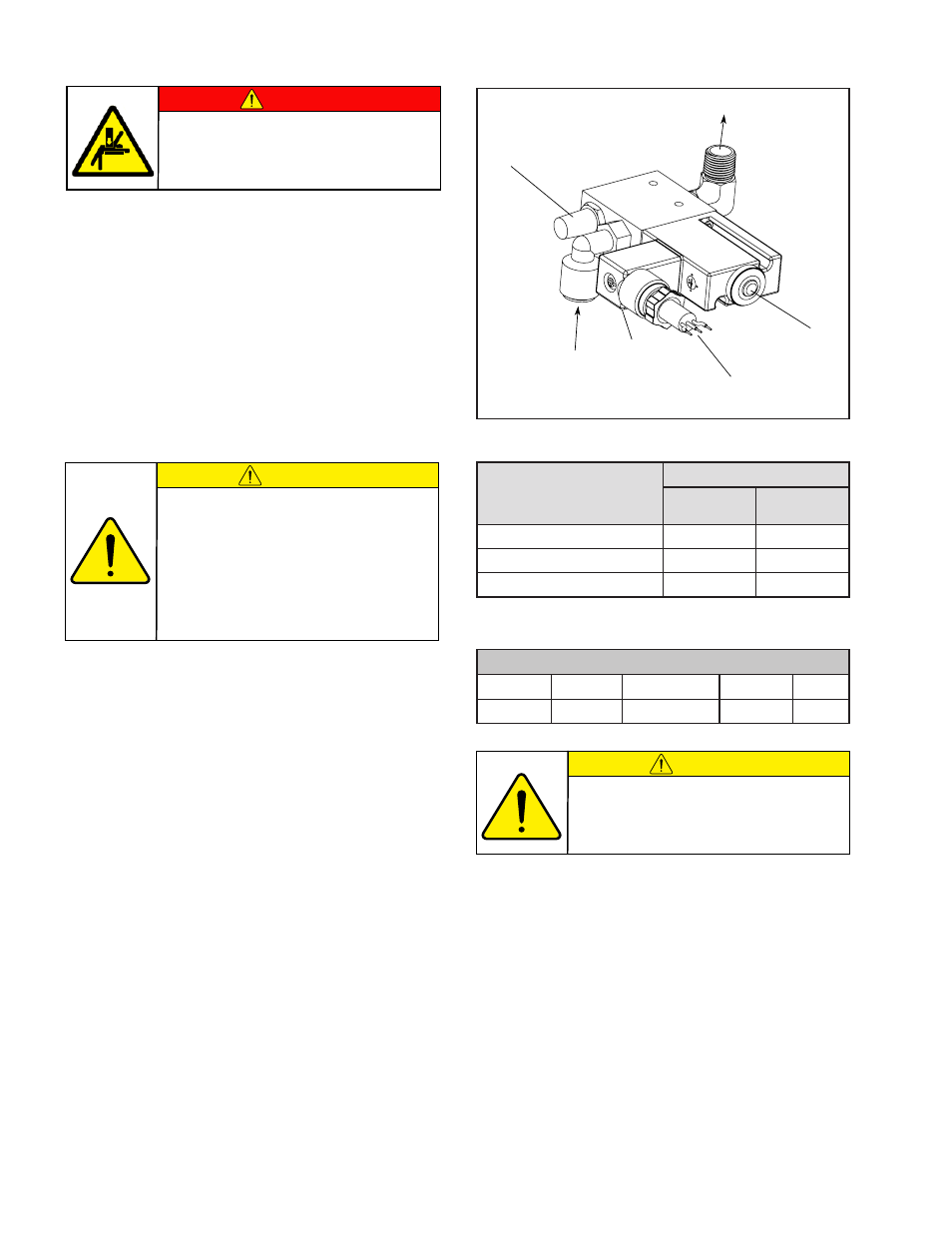

With Optional Solenoid:

If you are using the optional Solenoid Valve (Nexen Part

#964650), the Quick Exhaust Valve is unnecessary.

Assemble the optional Solenoid Valve directly to the

brake using the supplied fittings. Use Teflon tape and/

or pipe sealant on the threads. Refer to Figure 5.

DIN

Connector Cable Wire

Color

Valve

24 VDC

Valve Pin

Brown

+

1

White

-

2

Green

Ground

Ground

Table 3

Optional Solenoid Valve Specifications

Voltage

Power

Resistance

Current

Cv

24 VDC

4 W

145 ohms

.17 A

.25

DANGER

Support the load before disengaging the

brake. Failure to support the load could

result in serious bodily injury.

AIR CONNECTIONS (continued)

CAUTION

24 VDC valve connector has a

suppression diode installed across the

coil. Observe proper voltage polarity or

connector damage will result.

FIGURE 5 Optional Solenoid Valve Part #964650.

Exhaust

Silencer

To Brake

Air Supply

Tube Fitting

Manual

Override

DIN

Connector

Lead Wires

1/8 NPT

CAUTION

The brake will disengage if you

depress the domed button at the top

of the Solenoid Valve (if air pressure is

applied). The LED will illuminate when

the Solenoid Valve is actuated and the

brake is disengaged. Pressure needed

to disengage should NOT exceed 80

psi.

NOTE: Align the air inlet ports in the down position

to allow condensation to drain out of the air

chamber.

2. Attach the air supply line to the valve.

3. If using optional solenoid valve, attach DIN Connector

cable to valve by pressing DIN Connector onto valve

power pins and tightening DIN Connector fastener.

Then connect DIN Connector cable wires, using the

following chart, to the appropriate power supply, see

Table 3.