Nexen SBP09 965110 User Manual

Page 6

FORM NO. L-21059-E-0813

6

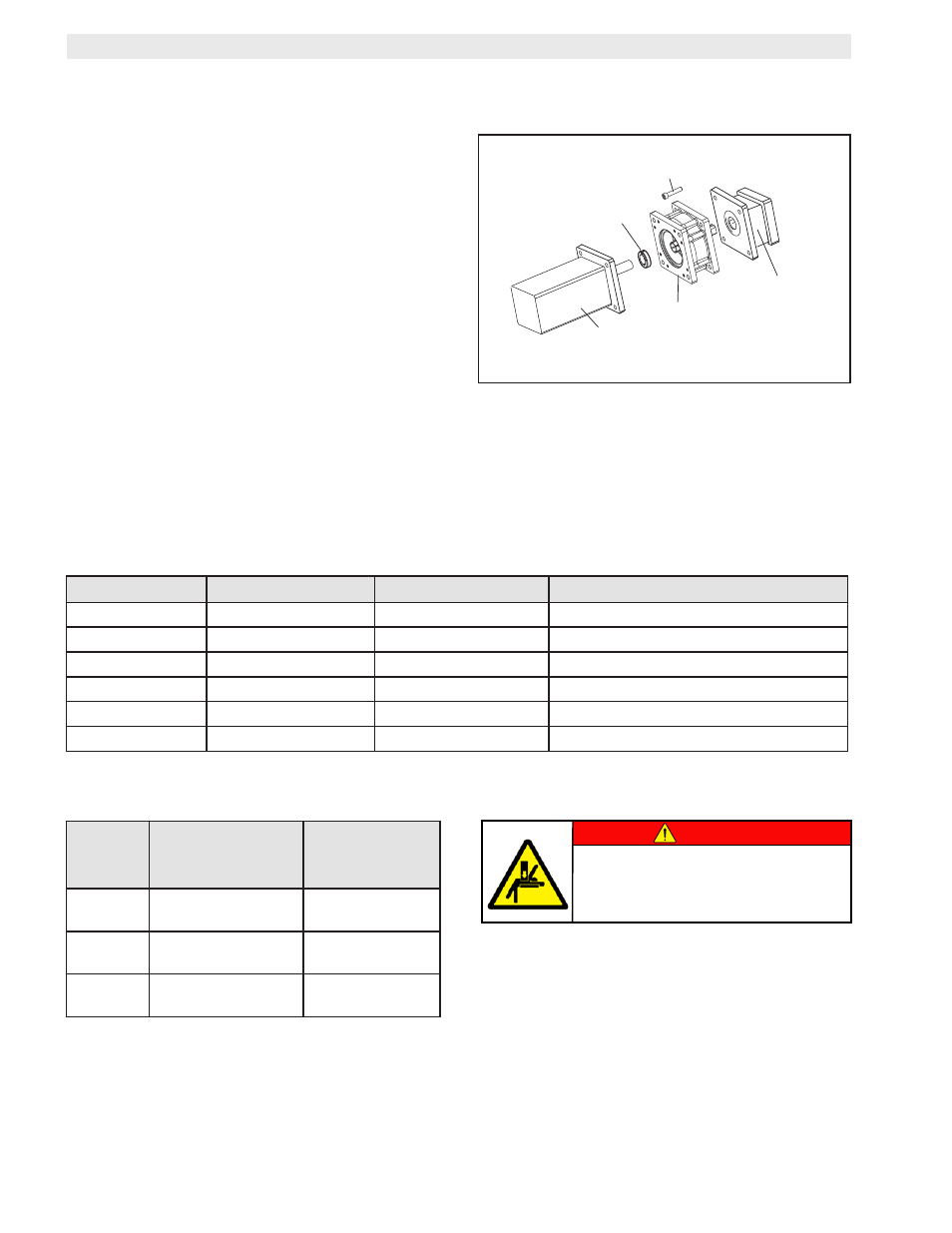

NOTE: Refer to Figure 4.

1. Mount the Servo Brake to the Motor Shaft by performing

steps 1-7 on page 5.

2. Insert the Output Shaft into the customer-supplied

gear reducer coupling. Use the supplied Rectangular

Key if required.

3. Bolt the flanges together using customer-supplied

M12 or M14 cap screws, washers and nuts. Before

assembly, apply a drop of Loctite® 242 (blue) to

the threads of each cap screw. Torque these cap

screws evenly (ie, those in opposite corners) to the

recommended torques listed in Table 2 (below).

4. Tighten the Coupling according to the instructions

supplied with the Gear Reducer.

5. Install any plugs or related items that are detailed in the

Gear Reducer instructions.

TABLE 1

INSTALLATION

TABLE 2

FIGURE 4

Clamping

Collar

(Item 7)

Input Flange

(Item 10)

Gear

Reducer

Customer-Supplied

Fastener

Square Motor with

Attached Flange

MOUNTED BETWEEN A MOTOR SHAFT AND A GEAR REDUCER

DANGER

Support the load before disengaging

the brake. Failure to support the load

could result in serious bodily injury.

Brake Model

Shaft Size

Cap Screw

Recommended Collar Screw Torque

Size 7

28mm-35mm

M6

16.00 Nm (142.0 in-lbs)

Size 7

35mm-48mm

M8 or 5/16-24

39.00 Nm (345.0 in-lbs)

Size 9

28mm-35mm

M6

16.00 Nm (142.0 in-lbs)

Size 9

35mm-48mm

M8 or 5/16-24

39.00 Nm (345.0 in-lbs)

Size 11

28mm-35mm

M6

16.00 Nm (142.0 in-lbs)

Size 11

35mm-48mm

M8 or 5/16-24

39.00 Nm (345.0 in-lbs)

Brake

Model

Socket Head

Cap Screw

(Customer Supplied)

Recommended

Fastening

Torque

Size 7

M12

158 Nm

(117 ft-lbs)

Size 9

M12

158 Nm

(117 ft-lbs)

Size 11

M14

180 Nm

(133 ft-lbs)