Air controls and programming, Cylinder mounting, Stand-alone mounting – Nexen Rod Locks 966195 User Manual

Page 8: Caution

8

FORM NO. L-21222-E-1211

AIR CONTROLS AND PROGRAMMING

Minimum release pressure = 4 bar [60 psi]

Maximum pressure = 8 bar [120 psi]

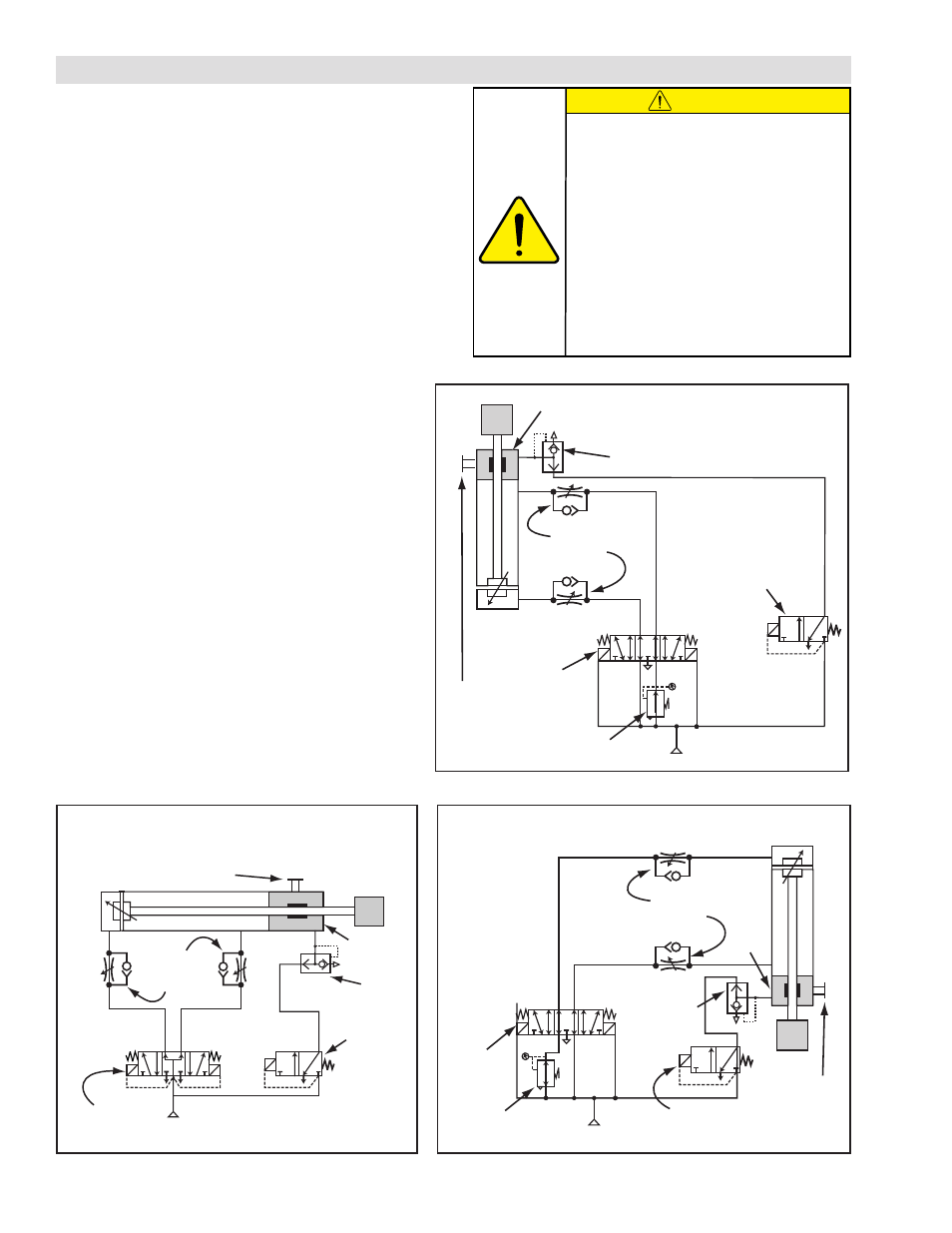

CYLINDER MOUNTING

Cylinder functioning is regulated by a 5/3 valve (use

cylinder manufacturer’s recommend Cv valves), center

open on the central port and supplied by exhaust

ports.

NOTE: Do not use a valve with a closed center.

This will cause unbalance in the piston if any of the

circuits leak.

One-directional flow reducers can be used to control

the speed of the cylinder rod. To ensure fast braking

of the rod, a quick exhaust valve can be installed on or

near the rod lock.

The normally closed (NC) solenoid valve directs the air

supply to the rod lock, keeping it disengaged until the

electrical signal is interrupted.

Vertical Mounting: The force on the piston must not

exceed its locking capacity when it is combined with

the force of the load.

Use of a 5/3 valve provides a braking effect and

maintains accurate rod positioning. Stopping precision

is determined by the rate of speed of the rod and loads

in motion.

Horizontal Mounting: Pressure is maintained on

both sides of the cylinder piston, keeping it balance,

preventing displacement of the rod upon release. Use

exhaust ports 3 and 5 (see below).

STAND-ALONE MOUNTING

Specifications match those of cylinder models listed

above.

Figure 3

W

Lowering

Control

Raising

Control

5

3

4

2

12

1

1

3

2

Rod Lock

Flow Control

Valves

3-Way Valve

Regulator

5/3 Valve

Quick Exhaust Valve

Manual Override,

Defaults to Lock

(If Equipped)

System Shown: Vertical mounting

with the load on top of the cylinder

Figure 5

System Shown: Cylinder control using a 5/3

valve with the center open on the central port.

Figure 4

System Shown: Cylinder control using a 5/3

valve with the center open on the central port.

W

1

3

5

3

4

2

2

12

Inward

Control

Outward

Control

Flow

Control

Valves

Rod Lock

3-Way

Valve

5/3 Valve

Quick

Exhaust

Valve

Manual Override, Defaults to Lock

(If Equipped)

Lowering

Control

Raising

Control

W

1

3

2

5

3

4

2

12

1

Rod

Lock

Flow Control

Valves

Regulator

5/3 Valve

3-Way

Valve

Quick

Exhaust

Valve

Manual Override,

Defaults to Lock

(If Equipped)

CAUTION

When programming the Nexen Rod

Lock in motion control systems, it is

critical to avoid repeated overlapping

conditions (i.e.: forced motion during the

engagement or disengagement of the Rod

Lock). Shaft damage will result. Design

the control system to use the Rod Lock in

static conditions.

Nexen’s Rod Lock must mount to a shaft

hardened to a minimum of HRC60 or hard-

chrome plated to a minimum thickness of

20 microns [0.0008 in] or damage to the

shaft may result.

- Rod Locks 966190 RLSSB 125-032-S-N 966074 RLSSB 100-025-S-N 966073 RLSSB 080-025-S-N 966072 RLSSB 063-020-S-N 966071 RLSSB 050-020-S-N 966070 RLSSB 040-016-S-N-MR 966028 RLSSB 040-016-S-N 966069 RLSSB 032-012-S-N 966068 RLSSB 125-032-S-A 966094 RLSSB 100-025-S-A 966093 RLSSB 080-025-S-A-MR 966025 RLSSB 080-025-S-A 966092 RLSSB 063-020-S-A 966091 RLSSB 050-020-S-A 966090 RLSSB 040-016-S-A 966089 RLSSB 032-012-S-A 966088 RLSSB 125-032-C-N-MR 966044 RLSSB 125-032-C-N 966034 RLSSB 080-025-C-N-MR 966042 RLSSB 080-025-C-N 966032 RLSSB 100-025-C-N-MR 966043 RLSSB 100-025-C-N 966033 RLSSB 063-020-C-N-MR 966041 RLSSB 063-020-C-N 966031 RLSSB 050-020-C-N-MR 966040 RLSSB 050-020-C-N 966030 RLSSB 040-016-C-N-MR 966039 RLSSB 040-016-C-N 966029 RLSSB 032-012-C-N-MR 966038 RLSSB 032-012-C-N 966036 RLSSB 125-032-C-A-MR 966024 RLSSB 125-032-C-A 966054 RLSSB 080-025-C-A-MR 966022 RLSSB 080-025-C-A 966052 RLSSB 100-025-C-A-MR 966023 RLSSB 100-025-C-A 966053 RLSSB 063-020-S-A-MR 966026 RLSSB 063-020-C-A-MR 966021 RLSSB 063-020-C-A 966051 RLSSB 050-020-C-A-MR 966020 RLSSB 050-020-C-A 966050 RLSSB 040-016-C-A-MR 966019 RLSSB 040-016-C-A 966049 RLSSB 032-012-C-A-MR 966046 RLSSB 032-012-C-A 966048 RLSSB 600-138-S-N 966176 RLSSB 500-138-S-N 966276 RLSSB 400-138-S-N 966262 RLSSB 325-100-S-N 966248 RLSSB 200-100-S-N 966234 RLSSB 500-100-S-N 966269 RLSSB 400-100-S-N 966255 RLSSB 400-100-S-N-MR 966149 RLSSB 250-063-S-N 966241 RLSSB 200-063-S-N 966227 RLSSB 600-175-S-A 966392 RLSSB 600-138-S-A 966284 RLSSB 500-138-S-A 966277 RLSSB 400-138-S-A 966263 RLSSB 325-100-S-A-MR 966137 RLSSB 325-100-S-A 966249 RLSSB 200-100-S-A 966235 RLSSB 500-100-S-A 966270 RLSSB 400-100-S-A 966256 RLSSB 400-100-S-A-MR 966148 RLSSB 250-063-S-A 966242 RLSSB 200-063-S-A 966228 RLSSB 150-063-S-A 966221 RLSSB 600-138-C-N-MR 966166 RLSSB 600-138-C-N 966362 RLSSB 500-138-C-N-MR 966165 RLSSB 500-138-C-N 966358 RLSSB 500-100-C-N 966356 RLSSB 400-138-C-N 966338 RLSSB 400-138-C-N-MR 966158 RLSSB 500-100-C-N-MR 966159 RLSSB 400-100-C-N-MR 966157 RLSSB 400-100-C-N 966336 RLSSB 325-100-C-N-MR 966139 RLSSB 325-100-C-N 966332 RLSSB 200-100-C-N-MR 966127 RLSSB 200-100-C-N 966308 RLSSB 150-063-S-N 966220 RLSSB 250-063-C-N-MR 966128 RLSSB 250-063-C-N 966326 RLSSB 200-063-C-N-MR 966126 RLSSB 200-063-C-N 966306 RLSSB 150-063-C-N-MR 966106 RLSSB 150-063-C-N 966303 RLSSB 600-175-C-A-MR 966385 RLSSB 600-138-C-A-MR 966162 RLSSB 600-138-C-A 966363 RLSSB 500-138-C-A-MR 966156 RLSSB 500-138-C-A 966359 RLSSB 400-138-C-A 966339 RLSSB 325-138-C-A-MR 966136 RLSSB 400-138-C-A-MR 966147 RLSSB 500-100-C-A-MR 966155 RLSSB 500-100-C-A 966357 RLSSB 400-100-C-A-MR 966144 RLSSB 400-100-C-A 966337 RLSSB 325-100-C-A-MR 966134 RLSSB 325-100-C-A 966333 RLSSB 250-100-C-A-MR 966124 RLSSB 200-100-C-A-MR 966117 RLSSB 200-100-C-A 966309 RLSSB 250-063-C-A-MR 966123 RLSSB 250-063-C-A 966327 RLSSB 200-063-C-A-MR 966116 RLSSB 200-063-C-A 966307 RLSSB 150-063-C-A-MR 966105 RLSSB 150-063-C-A 966304