Nexen Rod Locks 966195 User Manual

Page 5

5

FORM NO. L-21222-E-1211

1. Apply a constant supply of air, with a minimum of 4.1

bar (60 psi) air pressure to open (release) the Rod

Lock. Manual release option; apply the appropriate

amount of torque to the manual override mechanism

to open (release) the Rod Lock.

2. Remove the supplied rod from the inside of the Rod

Lock and keep for future use.

INSTALLATION

3. Carefully slide the Rod Lock over the cylinder rod

or guide rod, past the seal(s) and through the entire

assembly. Note: Cylinder (“C”) mounts, skip to

instruction #5.

4. “S” (stand-alone) series: Remove the air pressure to

engage the Rod Lock on the guide rod when it is in the

desired position.

5. “C” (cylinder mount) series: Carefully slide the Rod

Lock onto the cylinder rod toward the cylinder end cap.

The Rod Lock is piloted and sealed to the gland O.D.,

so some force is required. Press the Rod Lock onto

the end cap face as close as possible.

6. Using a corner-to-corner sequence, install and tighten

the mounting screws or tie rod nuts to approximately

75% of the final tightening torque. (See Table 1)

7. Using a calibrated torque wrench, tighten the fasteners

or nuts to the final torque specification using the same

corner-to-corner sequence.

8. Remove the air pressure to engage the Rod Lock on

the cylinder rod.

NOTE: “Rod” and “Shaft” refer to the same feature and

are used interchangeably.

The “S” (stand-alone) series Rod Locks are designed to

mount on round guide rods and are typically mounted in

accordance with the design of the machine.

The “C” (cylinder) series Rod Locks are designed to

mount directly to NFPA or ISO flush-mount air cylinders.

The “C” -mounted Rod Locks come with (4) mounting

screws. These screws are used to attach the Rod Lock

to cylinders with tapped holes in the interface or with

socket head, sleeve nuts. The mounting screws are not

necessary on cylinders equipped with threaded tie rods

/ nuts. Cylinders should be prepared with enough rod

length and tie rod length (if appropriate) to accommodate

the rod lock length.

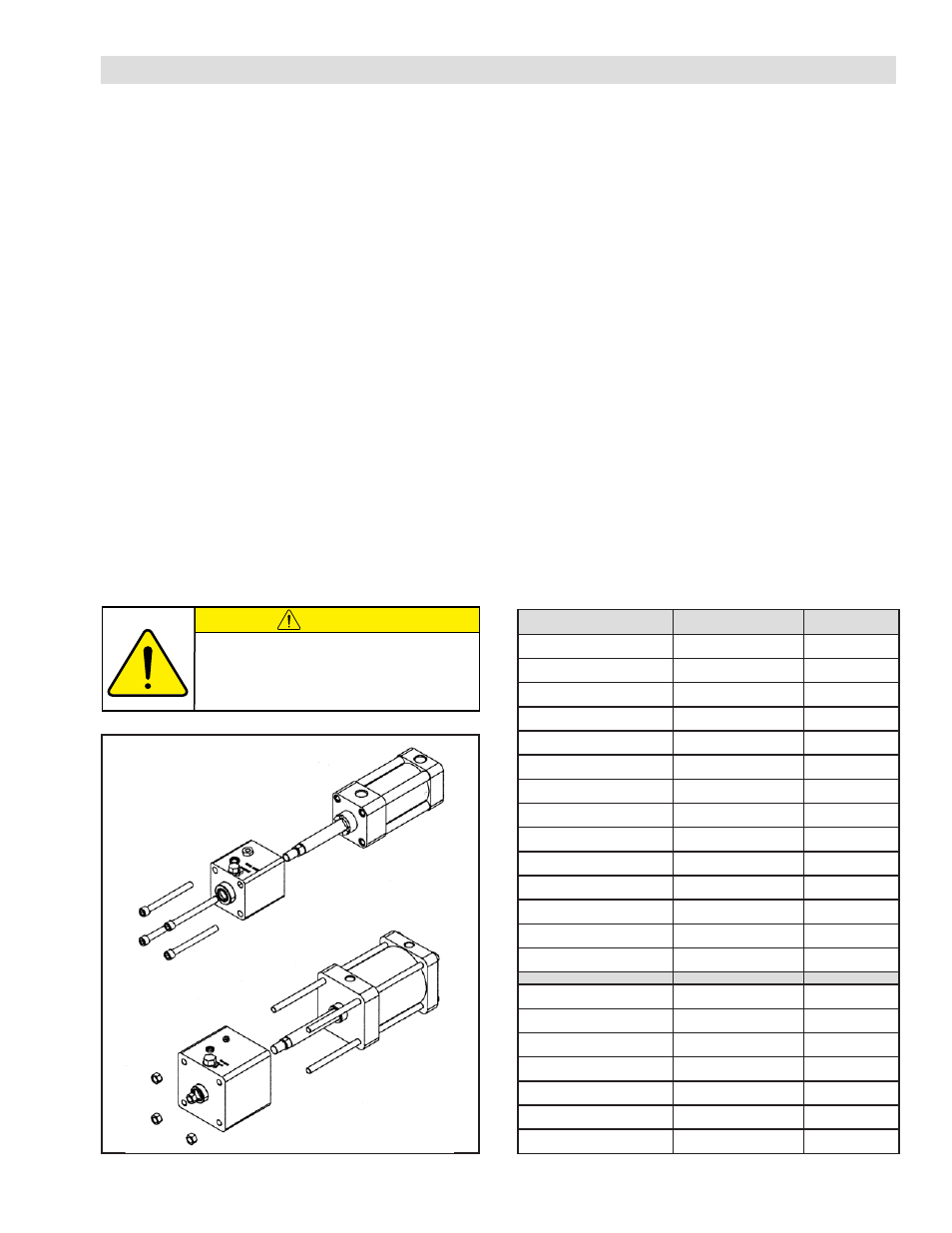

32MM to 6” Bores

8” Bores

Figure 1

Rod Lock

Inch-Pounds

Nm

RLSSB 150-063

32-36

3.6-4.1

RLSSB 200-063

72-82

8-9

RLSSB 200-100

72-82

8-9

RLSSB 250-063

72-82

8-9

RLSSB 325-100

216-228

24-25.3

RLSSB 400-100

216-228

24-25.3

RLSSB 400-138

216-228

24-25.3

RLSSB 500-100

360-372

41-42

RLSSB 500-138

360-372

41-42

RLSSB 600-138

420-432

48-49

RLSSB 600-175

420-432

48-49

RLSS 800-138

960-972

109-115

RLSS 800-175

960-972

109-115

RLSS 800-250

960-972

109-115

RLSSB 032-012

30-38

3.4-4.3

RLSSB 040-016

30-38

3.4-4.3

RLSSB 050-020

66-100

7.5-11.3

RLSSB 063-020

66-100

7.5-11.3

RLSSB 080-025

156-230

18-26

RLSSB 100-025

156-230

18-26

RLSSB 125-032

400

45

Table 1 Fastener or Tie Rod Torque

CAUTION

Do not engage the Rod Lock without a

properly sized rod in place or damage to

the internal components may result. Refer

to the Rod Material section.

- Rod Locks 966190 RLSSB 125-032-S-N 966074 RLSSB 100-025-S-N 966073 RLSSB 080-025-S-N 966072 RLSSB 063-020-S-N 966071 RLSSB 050-020-S-N 966070 RLSSB 040-016-S-N-MR 966028 RLSSB 040-016-S-N 966069 RLSSB 032-012-S-N 966068 RLSSB 125-032-S-A 966094 RLSSB 100-025-S-A 966093 RLSSB 080-025-S-A-MR 966025 RLSSB 080-025-S-A 966092 RLSSB 063-020-S-A 966091 RLSSB 050-020-S-A 966090 RLSSB 040-016-S-A 966089 RLSSB 032-012-S-A 966088 RLSSB 125-032-C-N-MR 966044 RLSSB 125-032-C-N 966034 RLSSB 080-025-C-N-MR 966042 RLSSB 080-025-C-N 966032 RLSSB 100-025-C-N-MR 966043 RLSSB 100-025-C-N 966033 RLSSB 063-020-C-N-MR 966041 RLSSB 063-020-C-N 966031 RLSSB 050-020-C-N-MR 966040 RLSSB 050-020-C-N 966030 RLSSB 040-016-C-N-MR 966039 RLSSB 040-016-C-N 966029 RLSSB 032-012-C-N-MR 966038 RLSSB 032-012-C-N 966036 RLSSB 125-032-C-A-MR 966024 RLSSB 125-032-C-A 966054 RLSSB 080-025-C-A-MR 966022 RLSSB 080-025-C-A 966052 RLSSB 100-025-C-A-MR 966023 RLSSB 100-025-C-A 966053 RLSSB 063-020-S-A-MR 966026 RLSSB 063-020-C-A-MR 966021 RLSSB 063-020-C-A 966051 RLSSB 050-020-C-A-MR 966020 RLSSB 050-020-C-A 966050 RLSSB 040-016-C-A-MR 966019 RLSSB 040-016-C-A 966049 RLSSB 032-012-C-A-MR 966046 RLSSB 032-012-C-A 966048 RLSSB 600-138-S-N 966176 RLSSB 500-138-S-N 966276 RLSSB 400-138-S-N 966262 RLSSB 325-100-S-N 966248 RLSSB 200-100-S-N 966234 RLSSB 500-100-S-N 966269 RLSSB 400-100-S-N 966255 RLSSB 400-100-S-N-MR 966149 RLSSB 250-063-S-N 966241 RLSSB 200-063-S-N 966227 RLSSB 600-175-S-A 966392 RLSSB 600-138-S-A 966284 RLSSB 500-138-S-A 966277 RLSSB 400-138-S-A 966263 RLSSB 325-100-S-A-MR 966137 RLSSB 325-100-S-A 966249 RLSSB 200-100-S-A 966235 RLSSB 500-100-S-A 966270 RLSSB 400-100-S-A 966256 RLSSB 400-100-S-A-MR 966148 RLSSB 250-063-S-A 966242 RLSSB 200-063-S-A 966228 RLSSB 150-063-S-A 966221 RLSSB 600-138-C-N-MR 966166 RLSSB 600-138-C-N 966362 RLSSB 500-138-C-N-MR 966165 RLSSB 500-138-C-N 966358 RLSSB 500-100-C-N 966356 RLSSB 400-138-C-N 966338 RLSSB 400-138-C-N-MR 966158 RLSSB 500-100-C-N-MR 966159 RLSSB 400-100-C-N-MR 966157 RLSSB 400-100-C-N 966336 RLSSB 325-100-C-N-MR 966139 RLSSB 325-100-C-N 966332 RLSSB 200-100-C-N-MR 966127 RLSSB 200-100-C-N 966308 RLSSB 150-063-S-N 966220 RLSSB 250-063-C-N-MR 966128 RLSSB 250-063-C-N 966326 RLSSB 200-063-C-N-MR 966126 RLSSB 200-063-C-N 966306 RLSSB 150-063-C-N-MR 966106 RLSSB 150-063-C-N 966303 RLSSB 600-175-C-A-MR 966385 RLSSB 600-138-C-A-MR 966162 RLSSB 600-138-C-A 966363 RLSSB 500-138-C-A-MR 966156 RLSSB 500-138-C-A 966359 RLSSB 400-138-C-A 966339 RLSSB 325-138-C-A-MR 966136 RLSSB 400-138-C-A-MR 966147 RLSSB 500-100-C-A-MR 966155 RLSSB 500-100-C-A 966357 RLSSB 400-100-C-A-MR 966144 RLSSB 400-100-C-A 966337 RLSSB 325-100-C-A-MR 966134 RLSSB 325-100-C-A 966333 RLSSB 250-100-C-A-MR 966124 RLSSB 200-100-C-A-MR 966117 RLSSB 200-100-C-A 966309 RLSSB 250-063-C-A-MR 966123 RLSSB 250-063-C-A 966327 RLSSB 200-063-C-A-MR 966116 RLSSB 200-063-C-A 966307 RLSSB 150-063-C-A-MR 966105 RLSSB 150-063-C-A 966304