Mounting on a rail – Nexen TCC-7 835168 User Manual

Page 7

7

FORM NO. L-21600-E-0411

NOTE: The Rail Brake Shoe gap is set at the factory

to accommodate standard rails. Shoe gap is not

adjustable.

NOTE: Nexen rail brakes do not have an internal bearing

system and must be mounted in conjunction with at

least two bearing carriages (see figures 2 and 3). To

ensure proper alignment, the bearing carriages should

be mounted to a reference shoulder on the mounting

plate (see figures 2 and 3). Nexen rail brakes, however,

should not be aligned to the reference shoulder, but

must be allowed to self-center on the rail. Accurate

alignment is crucial to ensure proper brake function

and prevent facing drag. For successful alignment,

follow the installation steps below:

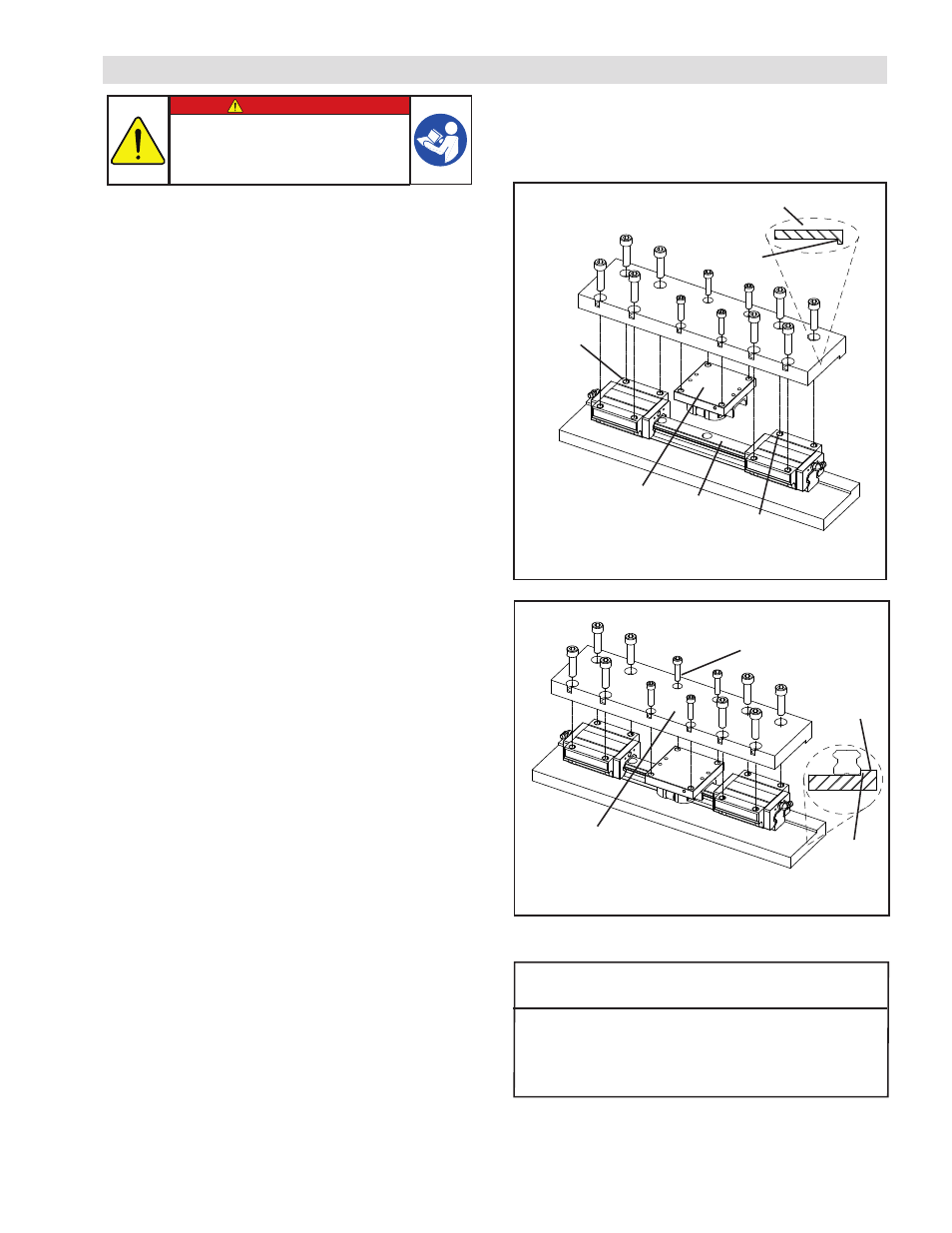

1. Nexen recommends a setup similar to the one shown

in Figures 2 and 3. Apply air pressure to the rail brake

to disengage it.

2. Slide the rail brake onto the rail. Position the rail brake

between two bearing carriages as shown.

3. Loosely assemble the mounting plate to the rail brake

and bearing carriages.

NOTE: RBR25; for THK SHS and INA KUVE models,

install the shim (shipped loose with these models)

between the mounting plate and the brake to match

bearing height.

4. Align the bearing carriages to the reference shoulder

and completely tighten the bearing carriage mounting

screws.

5. Finger-tighten the rail brake mounting screws. Do not

over-tighten the screws at this point; the brake must

be allowed to shift slightly in the following step.

6. Engage the rail brake to lock it onto the rail. Disengage

and reengage it three successive times to ensure that

it centers on the rail.

7. With the rail brake engaged, completely tighten the

rail brake mounting screws.

8. Disengage the rail brake and slide the assembly

back and forth to check alignment. If the rail brake

consistently drags along the rail, repeat steps 3-7

to realign the brake. If the rail brake drags only in

certain locations along the rail, check and adjust rail

straightness in those areas. If realignment and rail

straightening do not fix problems with facing drag,

the disengagement pressure of the rail brake can be

increased to 5.0 bar [72 psi] to ensure a minimum of

.05 mm [.002”] facing-to-rail clearance per side.

Table 1

Model

Socket Head Cap Screw

1

Size

RBR20

M6 x 1.0

RBR25

M6 x 1.0

RBR30

M6 x 1.0

RBR35

M10 x 1.5

1 Important: Do not use flat-head screws for this installation.

Figure 2

*Customer Supplied

Bearing*

(2x min.)

Bearing*

Rail Brake

Rail*

Datum Plane

Table (end view)

Figure 3

Bolts*

Mounting

Plate*

*Customer Supplied

Mounting

Shoulder

Datum

Plane

MOUNTING ON A RAIL

DANGER

Rail brake alignment is critical for proper

function. Carefully follow steps 1-8 to ensure

a successful rail brake installation. Improper

installation can damage your system and

cause serious injury or death.

NOTE: Rail Brake must be disengaged with a minimum

of 60 psi before mounting on a rail. Apply air pressure to

disengage the Rail Brake (Refer to AIR CONNECTIONS

for details).