Danger, Caution – Nexen TCC-7 835168 User Manual

Page 6

FORM NO. L-21600-E-0411

6

DANGER

Support the load before disengaging

the Rail Brake. Failure to support

the load may result in serious injury

or death.

NOTE: Rail brakes are factory set to fully disengage

at 4.1 bar [60 psi]. However, a supplied air pressure

of 5.0 bar [72 psi] will ensure a minimum of .05 mm

[.002”] facing clearance on each side of the rail. The

additional clearance at 5.0 bar [72 psi] will help reduce

facing drag caused by rail irregularities.

The Rail Brake is equipped with one air inlet port used to

disengage the brake (Refer to Figure 1 for location).

NOTE: Clean air is important for proper Rail Brake

functioning. Debris inside the Rail Brake may inhibit

performance and/or decrease product life.

1. Route clean air to the Rail Brake using soft lines.

Supply adequate air pressure to ensure complete

disengagement.

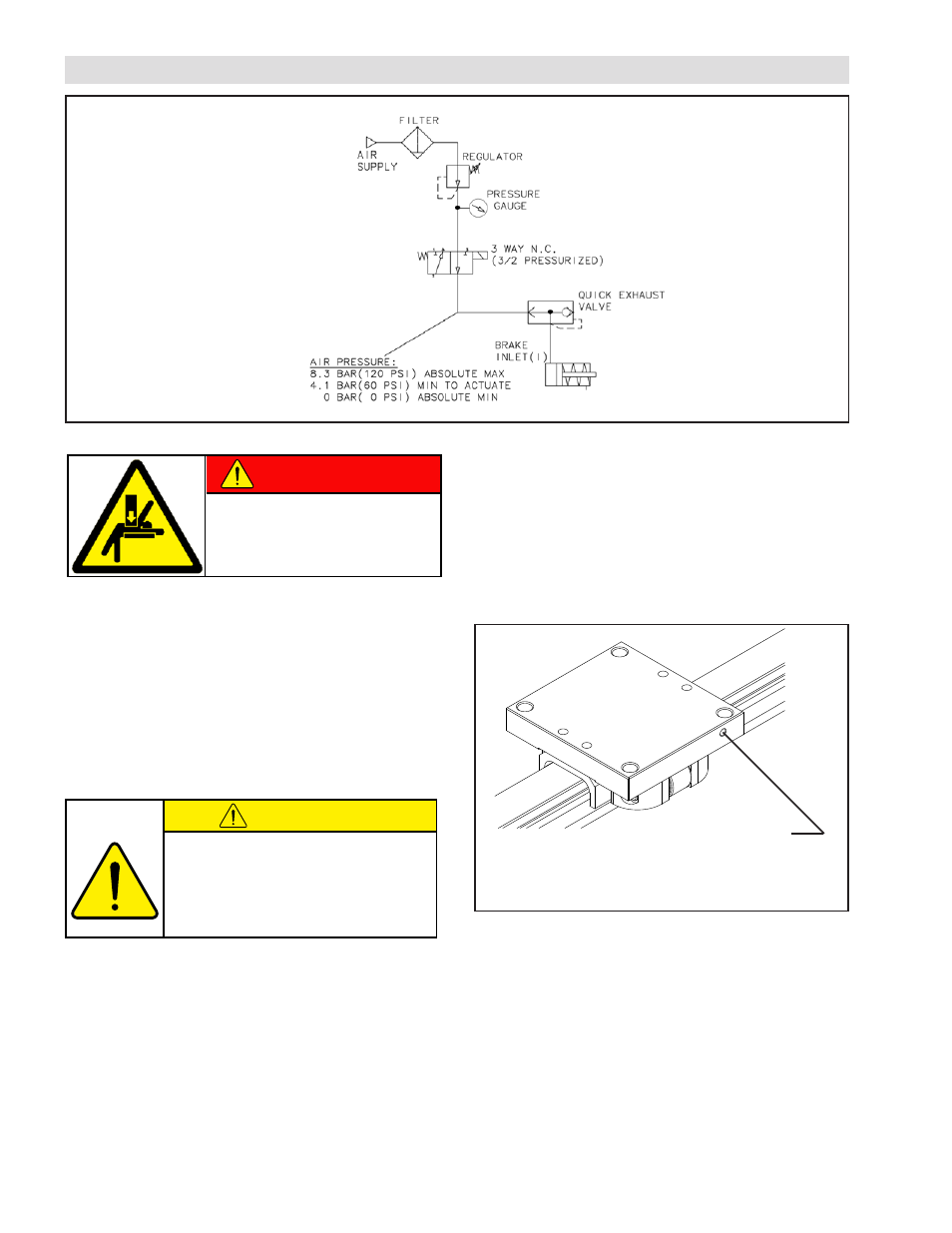

Figure 1

Disengagement

Air-inlet Port (M5 x .8)

(use customer-

supplied air fitting)

NOTE: For faster engagement and disengagement,

install the valve close to the Rail Brake. Increasing air

pressures will also speed the disengagement time, but

do not exceed 6.9 bar [100 psi] air pressure.

RELEASE PRESSURE / RAIL CLEARANCE

Air Circuit Diagram

AIR CONNECTIONS

CAUTION

Do not use rigid pipe or tubing when

connecting directly to the Brake.

Prevent unshielded air hoses from

rubbing on metal surfaces or edges,

as this will cause rapid deterioration of

the hose.