Technical data, Lubrication instructions – Metalfab 4P Series Vibrator User Manual

Page 3

3

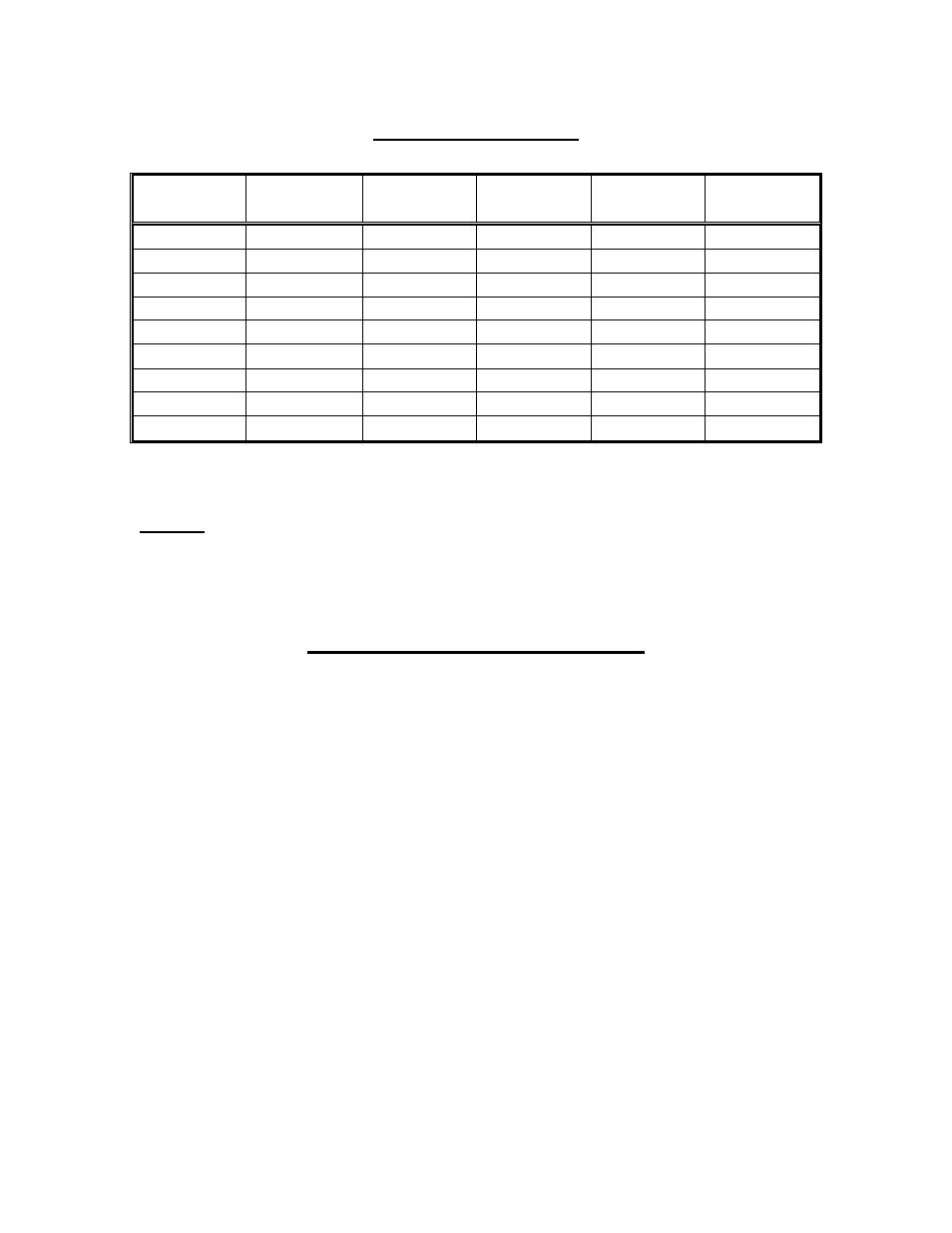

Technical Data

MODEL

AMPERES

230/460

H.P.

MAX.

FORCE

**DB

WEIGHT

4P-0.35 K

1.2/.6

_

300

60

31

4P-0.7 K

1.6/.8

_

700

63

36

4P-1 K

1.6/.8

_

1000

63

41

4P-1.4 K

3/1.5

1

1400

70

63

4P-2 K

4/2

1 _

2000

72

98

4P-3 K

6/3

2 _

3000

74

155

4P-5 K

6/3

3

5000

75

195

4P-10 K

7/3.5

5

10000

76

495

4P-15 K

11/5.5

7 _

15000

76

660

1800 VIBRATIONS PER MINUTE

NOTE:

MOST VIBRATORS AVAILABLE IN BOTH 50 & 60 CYCLES.

230/460 OR 575 VOLT

**DECIBEL AT 3’ (1 METER) ON A SCALE

ALL VIBRATORS ARE CSA APPROVED.

Lubrication Instructions

The ball bearings in the 4P-0.35K, 4P-0.75K and 4P-1K are pre-

lubricated for life. All other models have two roller bearings with

grease fittings. The life of the roller bearings reach far beyond the ball

bearings, however, the roller has a larger contact area than the ball

and needs more lubricant. Therefore, they have to be re-lubricated at

certain intervals. For 1725 RPM vibrators, every 1,000 to 2,000 hours

or every month for continuous duty. The amount of lubricant should

be 2.5 to 3 grams (two pumps with standard manual grease gun.) Do

not over grease. If too much grease is applied it will leak out. By

removing the end cover you will find out if the unit has been

excessively over greased. Clean out excess grease. The same amount

is on inside of bearings on stator side. If too heavy, unit should be

taken apart and cleaned. For vibrators without grease nipple, the

outside eccentric and bearing cover have to be removed. If the

bearing has a grease seal, remove and discard it. Remove as much as

possible of the old grease and repack bearing.