Warning – Bradford White TGHE-199I-N User Manual

Page 64

64

SECTION IX: MAINTENANCE

WARNING

Always turn off the electrical power supply, the manual gas valve, and the manual water control

valve whenever servicing this appliance.

KEEP THE WATER HEATER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

The EverHot

water heater should be checked annually by a qualified technician. Regular maintenance

will keep the water heater operating efficiently and help to assure reliable operation and a long service

life.

1. Remove and clean the inlet water filter screen. If a Y-type strainer or cartridge filter is used on

the cold water inlet to the water heater, inspect or clean as needed to assure full water flow to the

water heater.

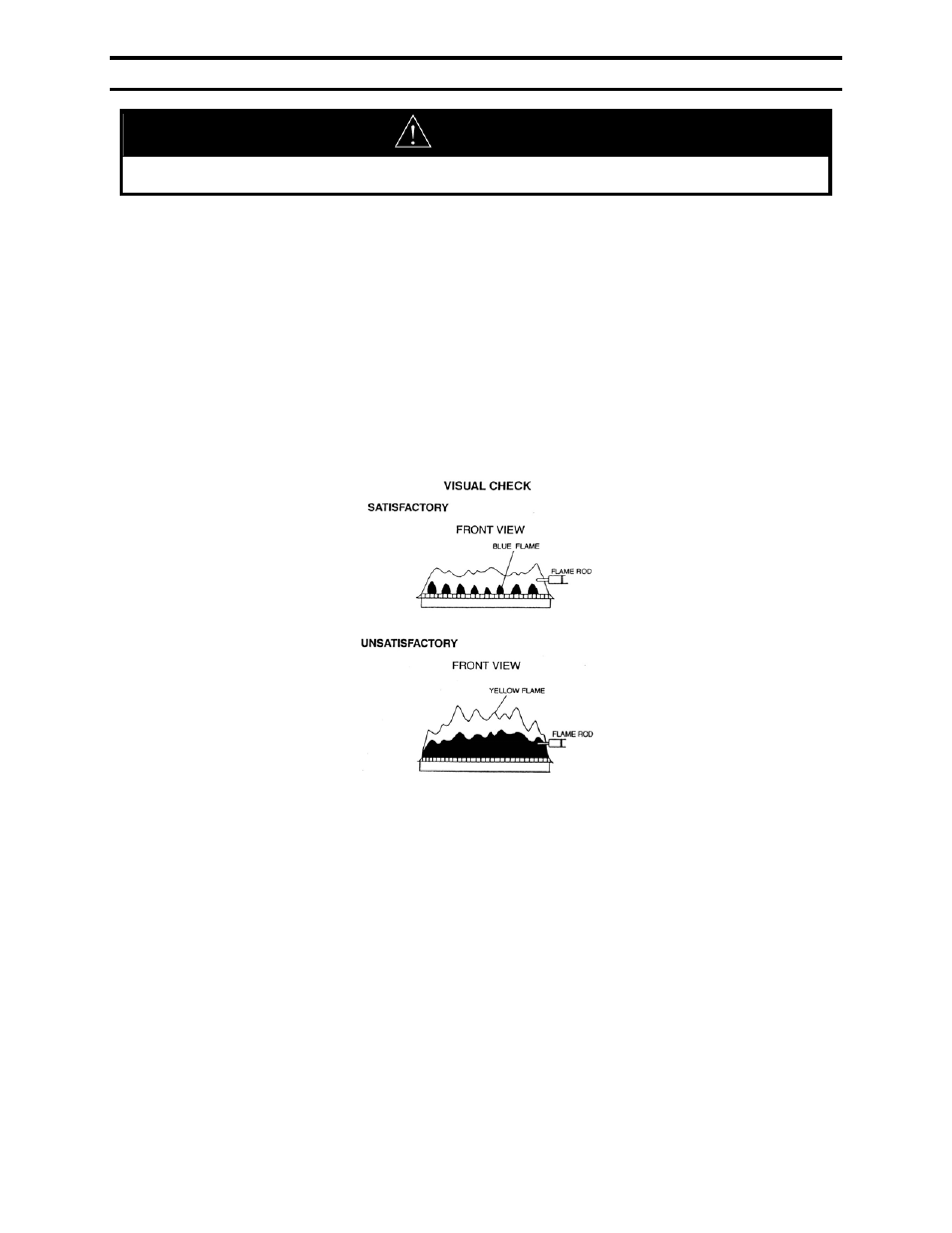

2. Visually inspect the burner flames. The flame must burn with a clear blue, stable flame (possibly

with orange tips). Refer to Figure 42 for satisfactory flame appearance. If the burner flame

appearance is not satisfactory or debris is visible on the burners, remove and clean with a

vacuum cleaner.

Figure 42.

Burner Flame Appearance.

3. Inspect entire venting system and vent terminal. Make sure all the venting connections are tight

and the gaskets are in good condition. Check the vent terminal openings for blockage and clean,

if necessary. Keep shrubs and vegetation clear of the vent terminal.

4. All electric motors are permanently lubricated and do not need oiling. Remove the combustion air

blower and clean wheel and housing with soft brush or vacuum.

5. If the “LC” code has been flashing on the display, the heat exchanger will need flushing to remove

lime and scale deposits. Refer to the “Flushing Procedure for Lime Scale Removal…” in Section

IX, “Maintenance.”

6. Check operation of the pressure relief valve. To check the relief valve, lift the lever at the end of

the valve several times. The valve should seat properly and operate freely. If water does not

flow, remove and inspect for obstructions or corrosion. Replace with a new valve of the

recommended size as necessary. A thorough inspection of the valve should be performed at

least every three years by removing the pressure relief valve from the outlet piping. Do not

attempt to repair the valve, as this could result in improper operation and explosion of the heat

exchanger and piping. In areas with poor water conditions, it may be necessary to inspect the

pressure relief valve more often than the recommended maintenance schedule.