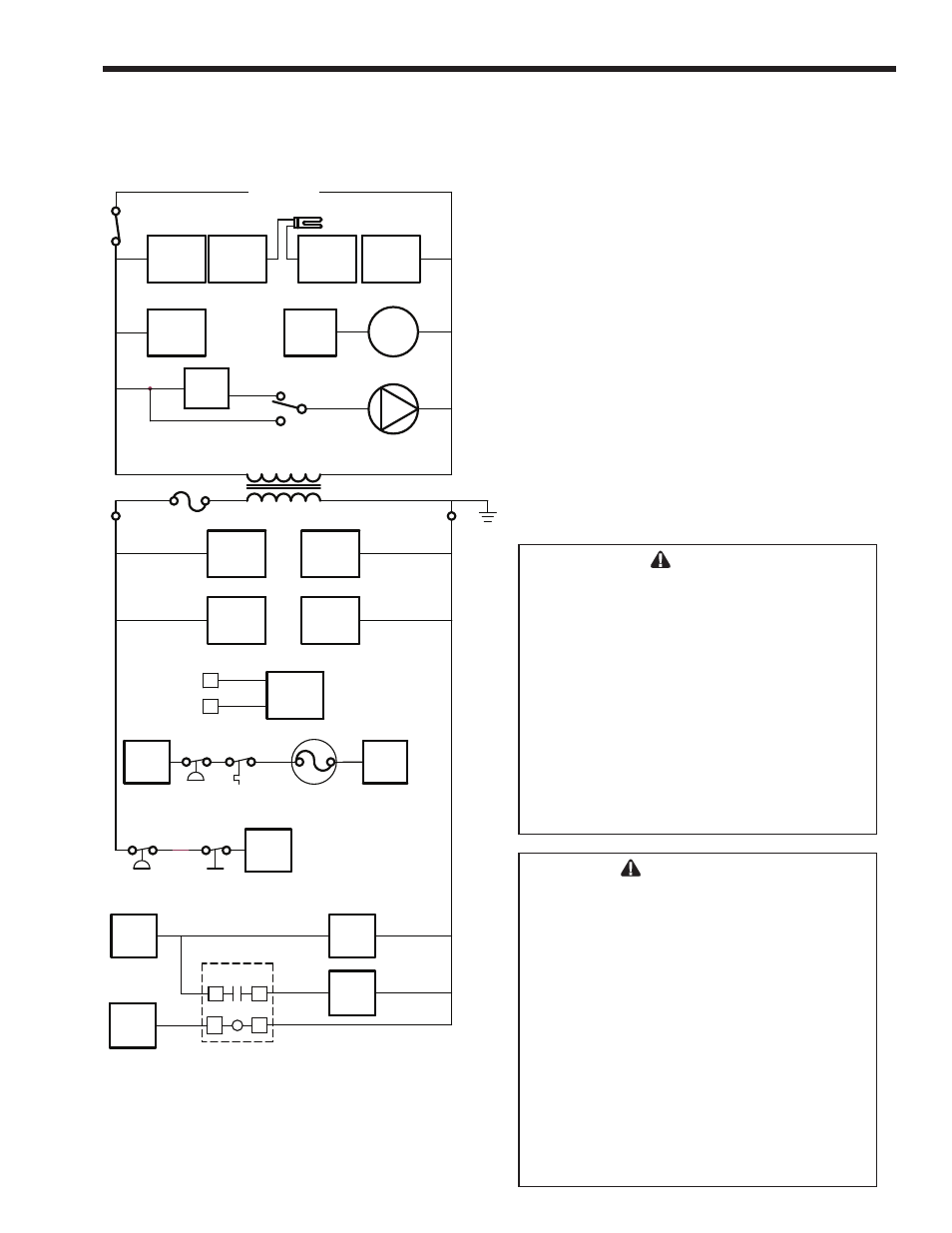

1 main power, 2 field wiring, Page 25 – Bradford White BMT2V0400 User Manual

Page 25

Brute Deluxe (200, 300, 400)

Page 25

STAGE 2

STAGE 1

CTL

BD

GAS

VALVE

GAS

VALVE

IGN CTL

VAL

FLOW

SW

PRSW

BURNER

IGN CTL

PSW

IGN CTL

TH

CNTRL

BD

FIELD

INTERLOCK

T

T

CNTRL

BD

2

4

CNTRL

BD

24V-

CNTRL

BD

PUMP

STATUS

SW

FUSIBLE LINK

MODEL 200

ONLY

MANUAL

RESET

HIGH LIMIT

VENT STK

PR SW

+24

IGN CTL

24V

BLOWER

IGN CTL

F2

IGN CTL

F1

MAIN PWR SW

120 VAC

HSI IGNITOR

IGN CTL

L2

IGN CTL

IGN/FS

IGN CTL

IGN/120

IGN CTL

L1

120 VAC

120 VAC

CLASS 2 50 VA

TRANSFORMER

PUMP

(IF EQUIPPED)

24 VAC

+24

1

W

CNTRL

BD

24V+

IGN CTL

GND

BK

R

BK

BLACK

BK

BROWN

BR

RED

R

ORANGE

O

YELLOW

Y

GREEN

G

BLUE

BL

VIOLET

V

GRAY

GY

SLATE

S

WHITE

W

WIRE

COLOR

DESIGNATION

-

+

+

-

1

INDUCER FAN

FIELD

WIRING

ON OFF

1 2 3 4

3.6

2.0

0.4

SWITCHED 120 VAC TO PUMP

120 VAC L

DHW CALL

COM CALL

HEAT CALL

OUT

COM

SYS

BOILER

SENSOR

4 3

2 1

POWER

HEAT CALL

DHW CALL

WWSD

CURVE

H2357600-

GY/V

BK

GY/BK

GY/BK

V/W

BR/BK

BR/BLK

G

W

BK

BK

BL/R

IGN/FS

E0253400

VAL

IGN

240

L1

PSW

GND

F1

F2

24

VAC

TH

FC -

IGN

120

L2

Y

BL/R

FIELD

INTERLOCK

BL/R

F1

BL/R

FUSE

BK

R/W

Y

G

TRANSFORMER

115 VAC INPUT

24 VAC OUTPUT

24V

115V

L1

BK

W

W

W

POWER

BK

BK

BK

BK

L2

W

PUMP

PUMP LOAD MUST NOT

EXCEED 5 AMPS.

G

G

BK

W

BK

BK

W

PUMP

STATUS

SWITCH

CONNECTOR

SHOWN FROM

REAR OF BOARD

BK

R

SENSOR

Y

Y

Y

R/BK

R

Y

R

Y

BL

R/BK

BR/BK

BR/R

Y

RELAY

FOR

2-STAGE

VENT STACK

PRESSURE

SWITCH

BL/W

BL/R

HIGH

TEMPERATURE

LIMIT

MANUAL RESET

MANUAL RESET

TEMPERATURE LIMIT

SWITCH

FOR SIZE 200 ONLY

ST.1

6V

ST.2

6V

Y/BLK

Y/BLK

BR/R

BR/BLK

STAGE 2

GAS VALVE

STAGE 1

GAS VALVE

PRESSURE

SWITCH

AIR

BOX/BURNER

FLOW

SWITCH

BLOWER

BL

R/BK

R/BK

BK

+

6

5

3

4

2

1

R

TB1

FIELD

FIELD

+24

-24

-24

+24

BL

R

BK

NO

C

NC

IGNITOR

V/W

V/W

R

NO

P

C

8

7

4

RELAY

6

3

Figure 16. Logic Diagram, ON/OFF Boiler or Water Heater.

SECTION 5.

Electrical Connections

Single pole switches, including those of safety

controls and protective devices must not be wired in a

grounded line.

NOTE: All internal electrical components have been

pre-wired. No attempt should be made to connect

electrical wires to any other location except the

wiring box.

5.1 Main Power

Connect a 15 amp. fused, 120-volt supply to

the main power switch. Both hot and neutral wires

are provided for connections inside the boiler jacket.

Ground wire can be connected to the grounding screw

in the box.

Wiring diagrams are shown in

Figures 15 - 16

.

5.2 Field Wiring

Field Installed Pump: See

Figure 15

, Wiring

Diagram. Do not exceed 5 amps or control damage

could occur.

WARNING

The appliance must be electrically grounded

in accordance with the requirements of the

authority having jurisdiction or, in the absence

of such requirements, with the latest edition

of the National Electrical Code, ANSI/NFPA

70, in the U.S. and with latest edition of CSA

C22.1 Canadian Electrical Code, Part 1, in

Canada. Do not rely on the gas or water

piping to ground the metal parts of the boiler.

Plastic pipe or dielectric unions may isolate the

boiler electrically. Service and maintenance

personnel, who work on or around the boiler,

may be standing on wet floors and could be

electrocuted by an ungrounded boiler.

AVERTISSEMENT

L’appareil doit être relié à la terre

conformément aux exigences de la

réglementation locale ou, en l’absence d’une

telle réglementation, à la plus récente édition

du National Electrical Code (Code national de

l’électricité) ANSI/NFPA 70 aux États-Unis, et

à la plus récente édition du Code Canadien

de l’électricité 1

ère

partie (Canadian Electrical

Code Part 1) CSA C22.1, au Canada. N’utilisez

pas les tuyauteries d’eau ou de gaz pour

mettre à la terre les pièces métalliques de la

chaudière; des tuyauteries en plastique ou des

raccords union diélectriques peuvent isoler

électriquement la chaudière. Les employés

qui sont appelés à travailler sur la chaudière

ou autour peuvent être électrocutés par une

chaudière qui n’est pas mise à la terre.