Bradford White BMT2V0400 User Manual

Page 17

Brute Deluxe (200, 300, 400)

Page 17

Model

(Size)

20°F

25°F

30°F

35°F

flow

gpm

H/L

feet

flow

gpm

H/L

feet

flow

gpm

H/L

feet

flow

gpm

H/L

feet

200

17

1.6

14

1.0

11

0.7

10

0.5

300

26

3.5

20

2.3

17

1.6

15

1.2

400

34

6.3

27

4.0

23

2.8

19

2.1

Metric Equivalent

Model

(Size)

11°C

14°C

17°C

19°C

flow

lpm

H/L

m

flow

lpm

H/L

m

flow

lpm

H/L

m

flow

lpm

H/L

m

200

64

0.5

51

0.3

43

0.2

37

0.2

300

97

1.1

77

0.7

64

0.5

55

0.4

400

129

1.9

103

1.2

86

0.9

74

0.6

Notes: gpm = gallons per minute, lpm = liters per minute,

H/L = head loss, ft = head loss in feet,

m = head loss in meters.

Maximum temperature rise is 35°F (19°C), as shown.

Head loss is for boiler’s heat exchanger only.

N/R = not recommended.

Table 8. Water Flow Requirements - MT2H.

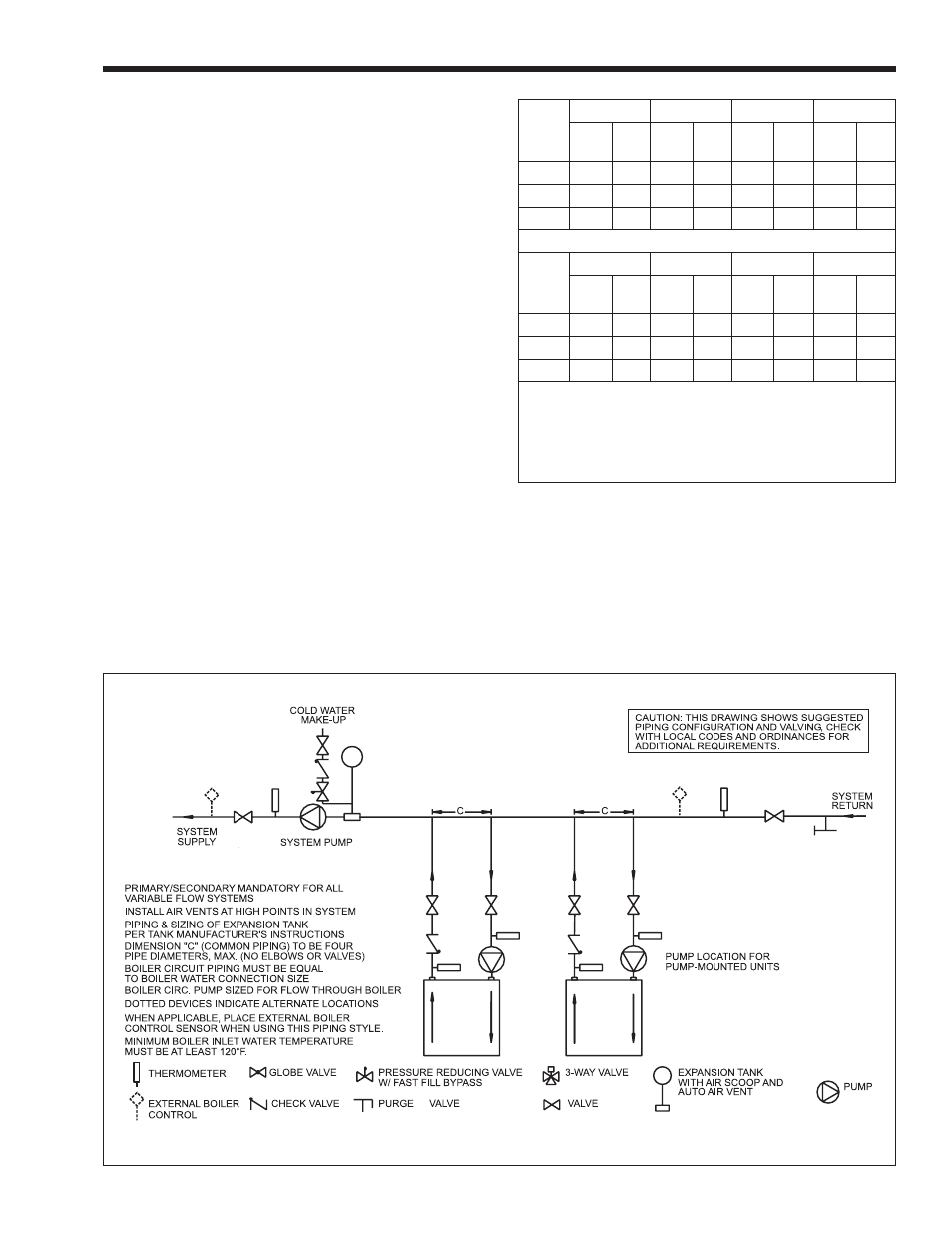

Figure 4. Hydronic Piping — Multiple Boilers, Primary Secondary System.

water flow requirements by 15%, and increase the

head loss requirements by 20%.

Power outage, interruption of gas supply, failure

of system components, activation of safety devices,

etc., may prevent a boiler from firing. Any time a

boiler is subjected to freezing conditions, and the

boiler is not able to fire, and/or the water is not

able to circulate, there is a risk of freezing in the

boiler or in the pipes in the system. When water

freezes, it expands. This can result in bursting of

pipes in the system, or damage to the boiler, which

could result in leaking or flooding conditions.

IMPORTANT NOTES: Different glycol products

may provide varying degrees of protection.

Glycol products must be maintained properly in a

heating system, or they may become ineffective.

Consult the glycol specifications, or the glycol

manufacturer, for information about specific

products, maintenance of solutions, and set up

according to your particular conditions. Never use