5e flow requirements, 5f chilled water systems, 5g oxygen permeable systems – Bradford White BJVS225 User Manual

Page 18: 5h anti-freeze

Bradford White Corp

Page 18

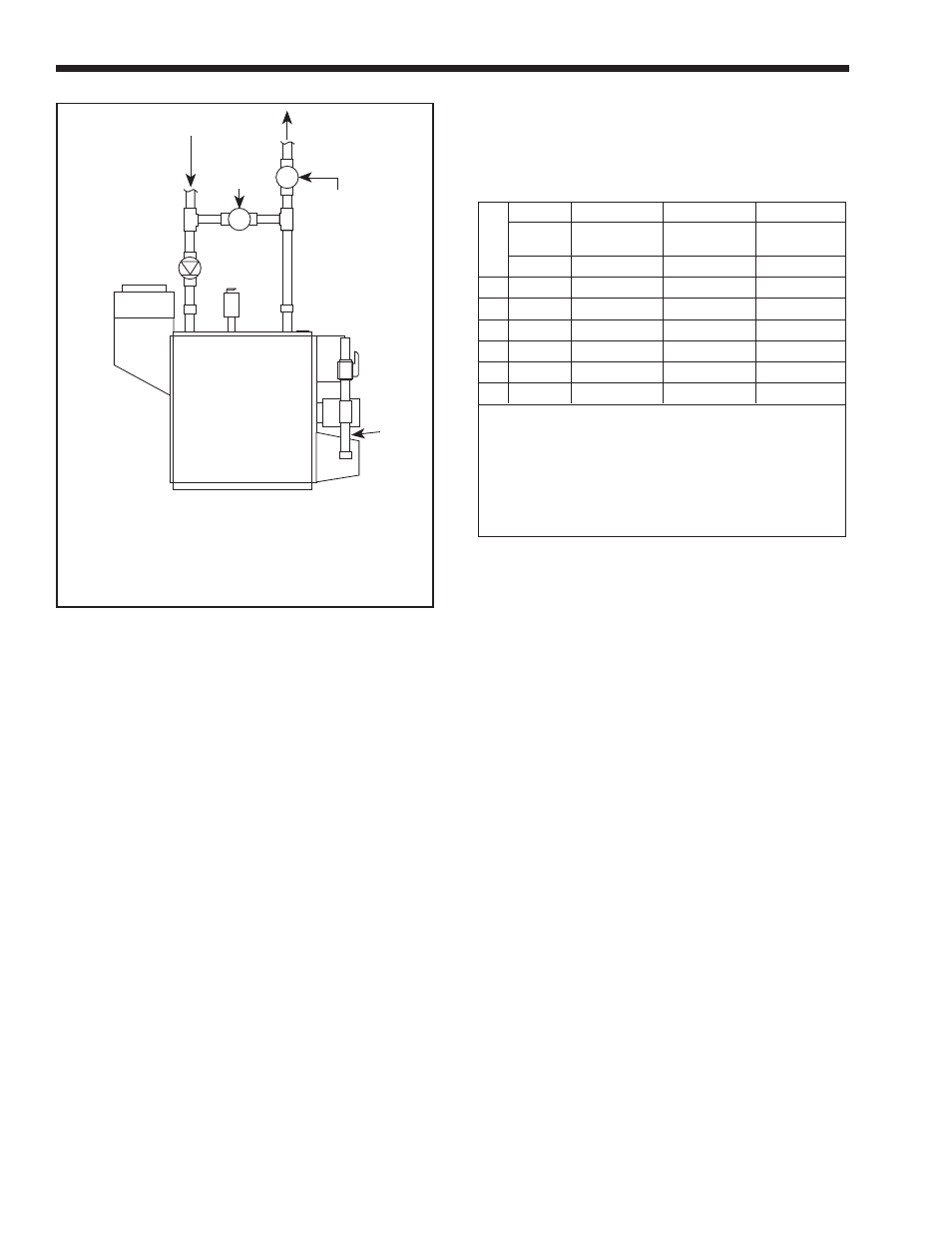

Figure 11. By-pass Piping.

Balancing Valve

or optional thermo-

static union, Bradford

White P/N 2400-030.

(Primary/Secondary

only)

To

System

From

System

In

(Return)

Out

(Supply)

Drip

Leg

Left Side View

A full size by-pass must be installed.

Balancing

Valve

5E Flow Requirements

All high recovery, low volume water boilers must have

adequate flow for efficient operation. Pump selection

is critical to this goal, and pumps should be selected

to provide for system design water temperature rise.

Table 7 details temperature rise and water flow (GPM)

for the Brute Mini boilers.

Damage from improper flow is not warranteed.

Failure to insure proper water flow through the

heat exchanger of the boiler will void the Bradford

White warranty. Flow can be verified by measuring

the difference in water temperatures between the

boiler inlet and outlet. For example: For a JV-100

installation, the inlet water temperature is 160°F

(71°C), and the outlet temperature is 180°F (82°C) at

Normal Input Rate from the rating plate. That means

there is a 20° (11°C) temperature rise through the

boiler. According to

Table 7, that would indicate a flow rate of 8 GPM

(0.5L/S). Temperature rise must be measured with the

longest (highest head) zone calling for heat alone.

Other factors to be considered before selecting a

pump are pipe size, the number of fittings throughout

the system, smoothness of the interior surface of the

pipe, the quantity of water flowing through the pipe,

whether a glycol solution is being used, and the total

length of piping in the system. Table 8 provides

example pump selection criteria using Type L copper

piping, one zone valve and up to eight elbows for

single zone systems. Consult the factory or a qualified

system designer if you have more fittings or different

size or type of pipe.

*A circulator and/or primary/secondary piping are required. Consult

factory.

1. Chart is based on 30°F (17°C) maximum temperature rise.

2. Calculations are based on Type L copper tubing with one zone

valve and eight elbows.

3. Typical circulating pumps:

1

/

25

HP=Taco 007, B&G LR-20 or

SLC-25, Grundfos UP15-42F, or equivalent.

1

/

12

HP=B&G LR-

12, Grundfos UP26-42F, or equivalent.

1

/

6

HP=B&G series HV,

Grundfos UP43-75, or equivalent.

Table 8. Maximum Suggested Circuit Length in Feet.

1/2" Pipe

3/4" Pipe

1" Pipe

1-1/4" Pipe

Size Pump

Pump

Pump

Pump

H.P.

H.P.

H.P.

H.P.

1/25 1/12 1/25 1/12 1/6 1/25 1/12 1/6 1/25 1/12 1/6

50 50 99 390 680

* * * * * * *

75

*

35 160 300 460 640

* * * * *

100

* *

77 150 260 330 620

* * * *

125

* *

27 80 140 170 360 600

* * *

160

* * *

25

72 57 160 330 190 480

*

225

* * * * * * *

110

*

69 330

5F Chilled Water Systems

If the boiler is installed in conjunction with

refrigeration systems, it shall be installed so that the

chilled medium is piped in parallel with the heating

boiler with appropriate valves to prevent the chilled

medium from entering the heating boiler.

When boiler piping is connected to heating

coils, which are in close proximity to refrigerated air

circulation, there must be flow control valves or other

automatic methods to prevent gravity circulation of the

boiler water during the cooling cycle.

5G Oxygen Permeable Systems

The JV boiler must not be direct connected to a

heating system utilizing oxygen permeable tubing.

Provide a water-to-water heat exchanger between

systems to prevent corrosion of ferrous metals such

as the boiler’s piping wet walls, etc. Air elimination

devices are not sufficient protection, and corrosion

damage is not covered under the limited warranty.

5H Anti-Freeze

Non-toxic HVAC anti-freeze may be added to the

hydronic system provided the concentration does

not exceed 50%, and the anti-freeze contains an anti

foamant and rust inhibitor. Follow the anti-freeze

manufacturer’s recommendations for yearly or

biannual replacement of system anti-freeze. Never use

automotive anti-freeze in a boiler system.