3b. venting – Bradford White BJVS225 User Manual

Page 10

Bradford White Corp

Page 10

be wired into the boiler control circuit to prevent the

boiler from firing unless the blower is operating.

The boiler must be completely isolated and

protected from any source of corrosive chemical

fumes such as those emitted by trichloroethylene,

perchloroethylene, chlorine, etc.

3B. Venting

Vent Categories: Brute Mini JVS is a natural draft

appliance for Category I venting only. JVH is a

fan-assisted product that can be vented vertically in a

properly-designed Category I system, or can be vented

horizontally as a Category III appliance, per this

installation manual.

WARNING

This boiler must be vented in accordance with

Part 7, Venting of Equipment, of the latest edition

of the National Fuel Gas code, ANSI Z223.1 and

all applicable local building codes. In Canada,

follow CAN/CGA B149 Installation codes.

Improper venting of this appliance can result in

excessive levels of carbon monoxide which can

result in severe personal injury or death!

AVERTISSEMENT

Cette chaudière doit être ventilé, conformément

aux dispositions de la partie 7, de la ventilation de

l'équipement, de la dernière édition du National

gaz carburant code, ANSI Z223.1 et tous les

codes du bâtiment locaux. Au Canada, CAN/

CGA B149 codes d'installation. Une mauvaise

ventilation de cet appareil peut entraîner des

niveaux excessifs de monoxyde de carbone qui

peut entraîner de graves blessures ou la mort!

The boiler vent collar must be fastened directly to

an unobstructed vent pipe with rustproof sheet metal

screws no longer than 1/2” (13mm) and located to

prevent interference with the inducer damper.

Do not weld the vent pipe to the boiler collar. The

weight of the stack must not rest on the boiler. The

boiler top must be easily removable for normal boiler

service and inspection.

IMPORTANT

Only JVH (induced draft) models may be side-wall

vented per Section 3D without the addition of a

properly sized and installed power venter.

JVS must be connected only using Category Type

I methods and materials per Section 3C. JVH may

be connected per Category I or III (See Section 3D)

methods and materials. See fuel gas code for more

information regarding your venting application.

IMPORTANT

Seulement JVH (induits projet) modèles peut être

paroi ventilé par chapitre 3D sans l'addition de la

bonne taille et de puissance installée venter. JVS

doivent être connectés uniquement en utilisant

Type de catégorie I méthodes et matériaux par

Section 3C. JVH peut être connecté par catégorie

I ou III (voir section 3D) Les méthodes et les

matériaux. Voir gaz combustible code pour plus

d'informations concernant votre application

d'aération.

Avoid terminating boiler vents near air conditioning

or air supply fans. The fans can pick up exhaust

flue products from the boiler and return them to the

building, creating a possible health hazard.

Avoid oversized vent pipe or extremely long runs

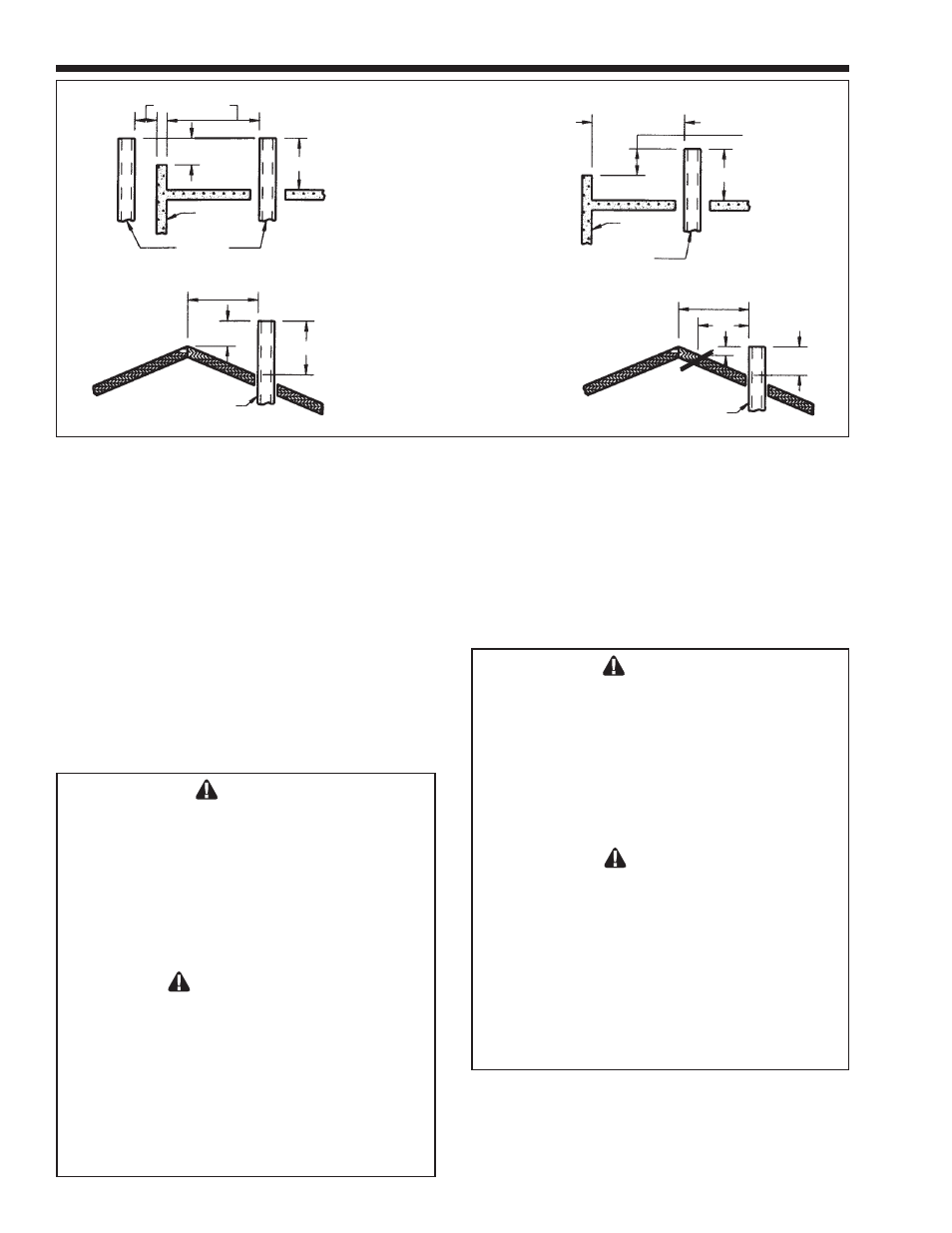

WALL OR

PARAPET

CHIMNEY

CHIMNEY

RIDGE

WALL OR

PARAPET

CHIMNEY

CHIMNEY

RIDGE

10 (3.0) OR

LESS

Figure 5. Vertical Vent Termination.

2 (0.6) MIN.

3 (0.9)

MIN.

10 (3.0)

OR LESS

2 (0.6)

MIN.

3 (0.9)

MIN.

3 (0.9)

MIN.

3 (0.9)

MIN.

2 (0.6)

MIN.

10 (3.0)

MORE THAN 10

(3.0)

MORE THAN 10

(3.0)

NOTE: NO HEIGHT

ABOVE PARAPET

REQUIRED WHEN

FROM WALLS OR

PARAPET IS MORE

THAN 10 FT. (3.0m)

TERMINATION

10 FT. (3.0m)

OR LESS FROM RIDGE,

WALL OR PARAPET

Dimensions in feet (m).