Bradford White BJVS225 User Manual

Page 29

Page 29

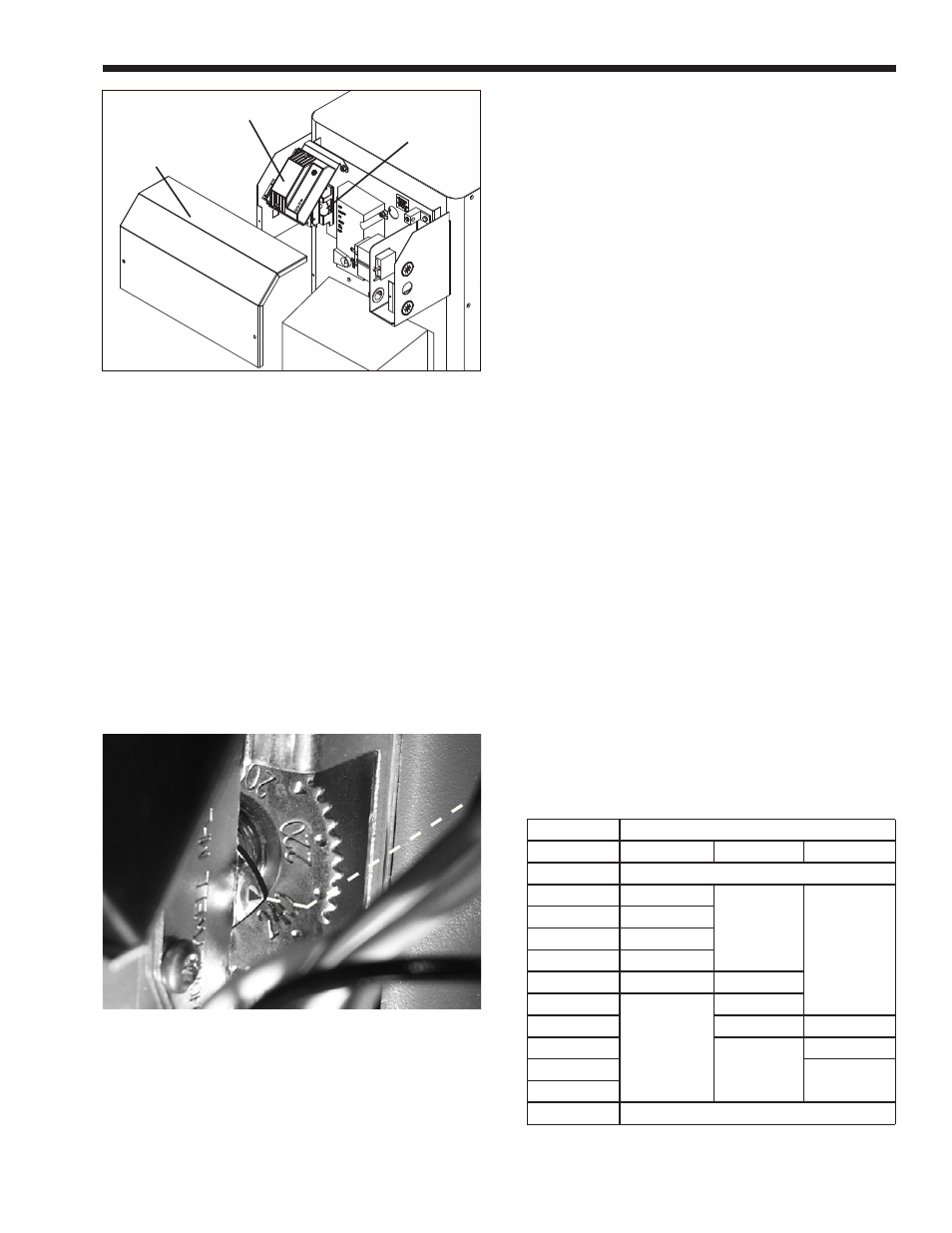

8.E Operating Temperature Controls

Note: The Temperature Controllers, the Dip switch

panel, and the LED panel can be found under the

Control Access Panel after removing the bolts.

Two temperature controls are now standard on all

JVS and JVH boilers.

1. The primary temperature controller maintains

all normal heating operations.

2. A secondary, mechanical high-limit aquastat

provides safe shutdown, should the primary

controller fail.

Important: If the secondary controller (See Figure

18A and Figure 18B) dial is set below 220F, it may

inhibit proper operation of the primary controller.

Prior to calling for technical support, please ensure

high limit control is set for at least 220F).

Figure 18B.

Secondary, mechanical high-limit

aquastat

Pump Operation. When a call for HEAT and/

or DHW is present the boiler pump will turn on. Post

purge can be selected via dip switch #5, Pump Post

Purge Inactive (Off) /Active 3 min. (On). In the On

position the pump will continue to run for 3 min after

the last call has been satisfied. When the dip switch is

Off there is no post purge of the pump, the pump turns

off immediately after the last call is removed. Bradford

White strongly recommends using a pump post purge.

During WWSD and a call for HEAT is present the

pump will remain off.

Pump Exercising The control exercises the

boiler pump every 3 days of inactivity. While the

control is exercising the pump all LEDs will turn off

and the power LED will flash for 10 seconds.

Staging (where applicable – factory setting):

Dip #1 is used to select the number of stages: 2-Stage

(Off) / Single Stage (On).

Note: Use of 2-Stage operation may reduce

efficiency.

For 2-stage operation, the first stage is cycled on

Proportional error and the second stage is cycled

based on PI according to a fixed algorithm. No user

adjustment is necessary.

Note: All stages are turned off when the water

outlet temperature reaches the Maximum setting that

is elected via dip switch #4, Boiler Maximum 210°F

(Off) / 190°F (On).

Auto Boiler Target Setpoint: Space Heating:

The boiler target temperature is automatically

determined from Space Heating and DHW

requirements. Space heating is based on outdoor reset.

When both a Heat Call and a DHW Call are present

at the same time, the control operates to provide the

higher boiler target temperature.

Heating Curve (Outdoor Temperature Reset)

The control uses a linear heating curve to calculate

a target setpoint. The following data are used

to calculate the target setpoint from the outdoor

temperature.

1. The heating curve or reset ratio (RR) is set by the

potentiometer with a range of 0.4 to 3.6.

2. The room temperature is fixed at 70 deg F.

Outdoor

Heating Curve=Reset Ratio (RR)=

Temp F

1.0

2.0

3.0

Boiler Target F

-30

170

210

210

-20

160

-10

150

0

140

10

130

190

20

130

170

30

150

190

40

130

160

50

130

60

70

WWSD OFF

Reset Ratio Calculation:

Boiler Target =

70 + RR *(70 - Actual Outdoor)

Table 9

1.

2.

Control Access

Panel

Figure 18A.