Bradford White M-2-TW-75T6BN User Manual

Page 14

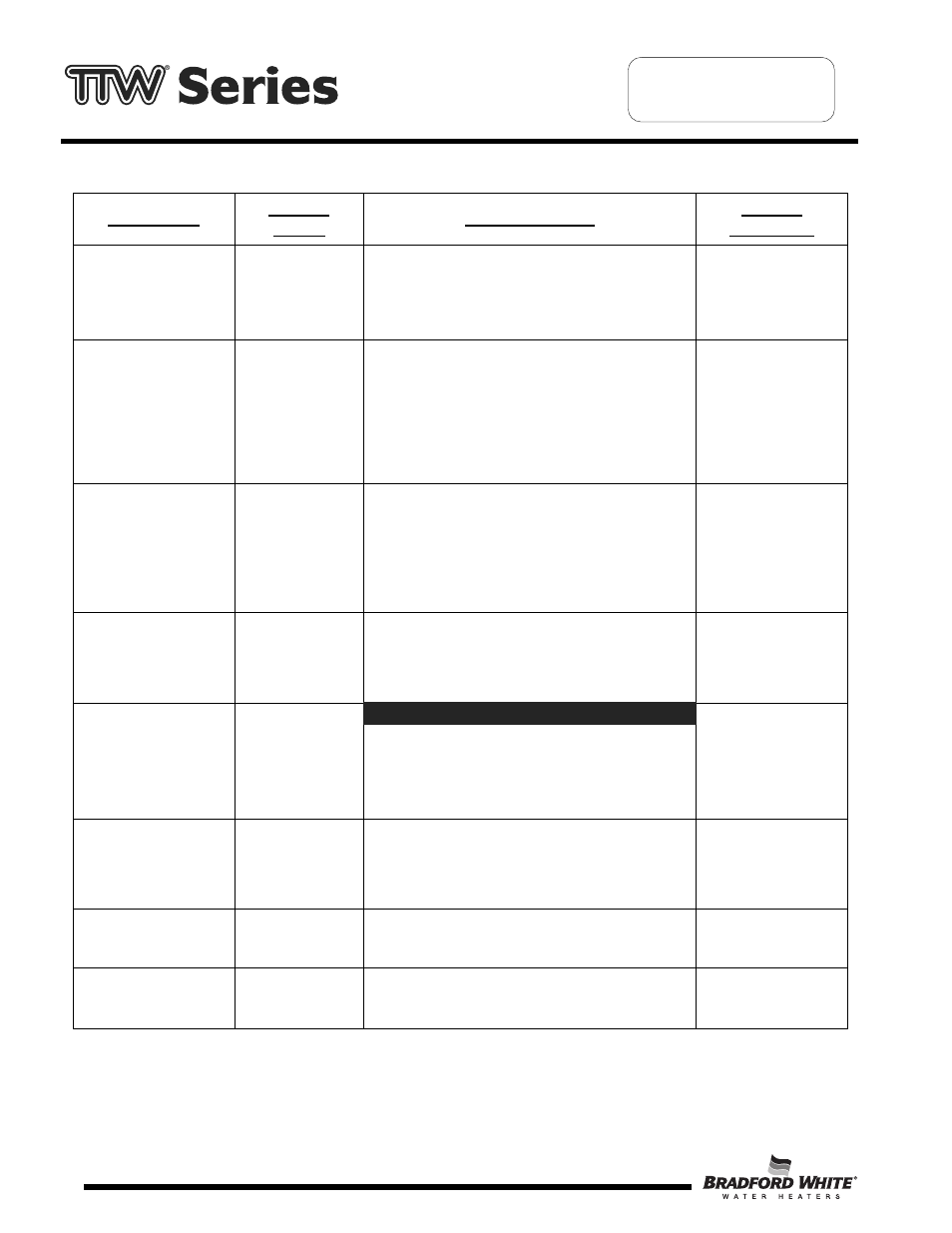

Six-four flash, three

second pause

Undesired-false

pilot flame

sensed.

System auto

resets.

Seven flash, three

second pause

Eight-one flash, three

second paus

Eight-three flash, three

second pause

Thermal well

sensor damaged

or unplugged

LED Status

Control

Status

Service

Procedure

Probable Cause

Pilot valve stuck in open position.

Replace gas control,

page 26

Page 28

Page 28

1. Damage to thermal well wire.

2. Thermal well sensor resistance out of range.

Page 24

Troubleshooting

Six-three flash, three

second pause

Pilot flame

extinguished.

System auto

resets.

1. Unstable pilot.

2. Pilot tube blocked or restricted.

3. Oxidation build up on pilot electrode.

4. Wire damage to pilot assembly or bad

connection at gas valve.

5. Insufficient combustion air.

6. Gas pressure is out of specification.

1. Page 15

2-4. Page 17

5. Refer to installation manual

Page 14

Six-two flash, three

second pause

Pressure switch

or blower temp

switch opened

during burner

operation.

System auto

resets.

1. Check vent or vent tables.

2 & 3 Page 18

4. Refer to venting section of

installation manual

5. Page 20

6 & 7 Page 22

1. Vent blockage or improper vent configuration.

2. Pressure switch tubing kinked or blocked.

3. Faulty pressure switch.

4. Vent termination being affected by wind

5. Blower not spinning up to speed.

6. Blower temp or exhaust temp too high

7. Faulty blower temperature switch.

Six-one flash, three

second pause

Failed to light

pilot.

System auto

resets.

1. Unstable pilot.

2. Pilot tube blocked or restricted.

3. Oxidation build up on pilot electrode.

4. Wire damage to pilot assembly or bad

connection at gas valve.

1. Page 15

2-4. Page 17

Eight-four flash, three

second pause

Gas valve fault

detected.

1. Control needs to be reset.

2. Control is wet or physically damaged.

1. Interrupt power supply

2. Replace gas control,

page 26

Flammable

Vapor Sensor

fault detected.

Flammable

Vapor Sensor

out of

specification.

• Indicates gasoline vapors were detected at potentially

explosive levels.

• Very Flammable Vapor Sensor (FVS) resistance is not below

25 KΩ.

• Check wiring to FVS and insure it is not shorted.

• Replace control if everything above checks out OK.

• Verify no gasoline vapors are still present.

• Reset the control by cycling power to the appliance or by

cycling the ON/OFF switch.

• Replace the Flammable Vapor Sensor element if a gasoline

spill event occurred.

WARNING: EXPLOSION HAZARD

Page 14

14