Gas supply line, Gas supply connection requirements, 7 gas supply line – B&C Technologies IS Series Commercial Ironer User Manual

Page 18: 8 gas supply connection requirements

tion must be made by a qualified electrician using the wiring diagram provided with the machine.

For personal safety and for proper operation, the machine must be grounded in accordance with

state and local codes and in the USA in accordance with the National Electric Code, article 250-96.

The ground connection must be to a proven earth ground, not to conduit or water pipes.

Insure that the control transformer taps are connected in accordance with the incoming line volt-

age. Verify connections as shown on the schematic with each machine.

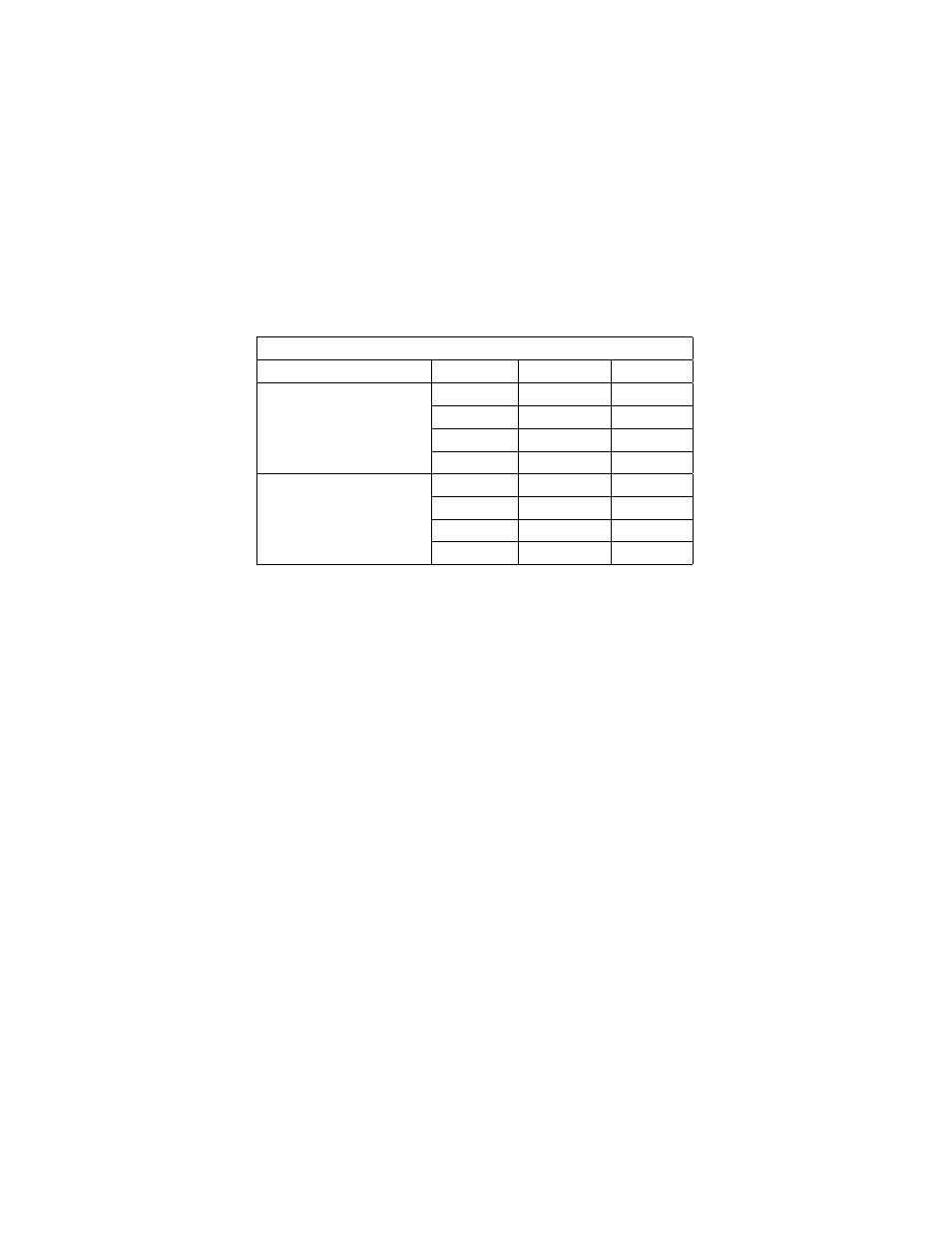

Table 3.4: IS Series Electrical Specifications

Gas/Steam Heat Models

Rating

Model

Amps

Breaker

208-230V, 50/60Hz

IS-14120

8A, 3ph

15

IS-18120

10A, 3ph

15

IS-24120

12A, 3ph

15

IS-32120

16A, 3ph

20

380-480V, 50/60Hz

IS-14120

4A, 3ph

15

IS-18120

5A, 3ph

15

IS-24120

6A, 3ph

15

IS-32120

8A, 3ph

15

3.3.7

Gas Supply Line

• 1” IPS pipe is recommended.

• 1” approved tubing is acceptable for lengths under 25 ft (6.1 m) if local codes and gas supplier

permit.

Must include 1/8” NPT minimum plugged tapping accessible for test gauge connection, immedi-

ately upstream of the gas connection to the ironer (see Figure 3.3 on page 16). Must include a

shutoff valve:

An individual manual shutoff valve must be installed within 6 feet (1.8m) of the equipment in

accordance with the National Fuel Gas Code, ANSI Z223.1. The location should be easy to reach

for opening and closing.

3.3.8

Gas Supply Connection Requirements

There are many methods by which the IS series Ironer can be connected to the gas supply. Follow-

ing are some guidelines for methods of connection.

15