Floor requirements, Gas requirements, Exhaust duct requirements – B&C Technologies IS Series Commercial Ironer User Manual

Page 14: 2 floor requirements, 3 gas requirements, 4 exhaust duct requirements

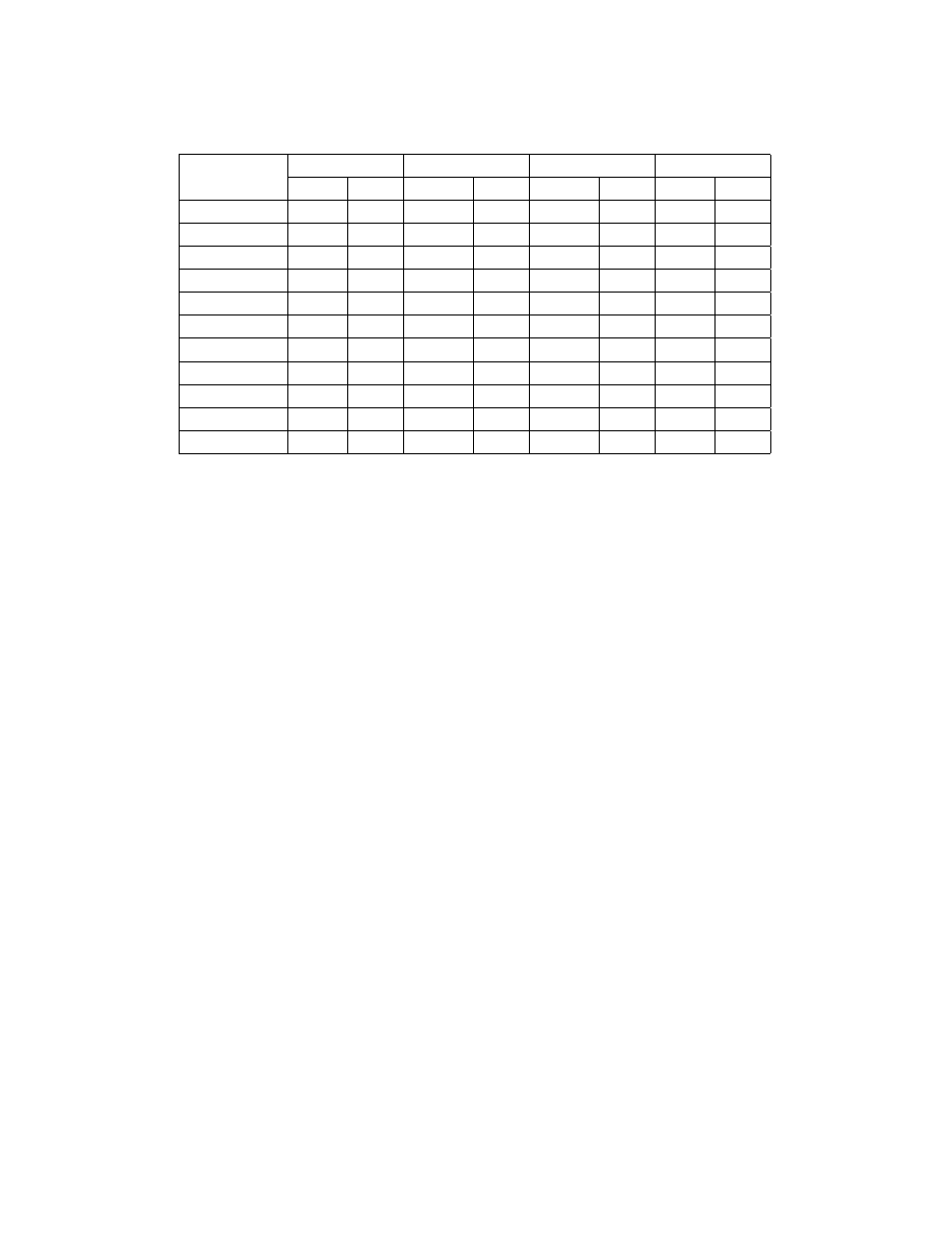

Table 3.1: IS Series Utility Reference

Dimension

IS-14120

IS-18120

IS-24120

IS-32120

inch

mm

inch

mm

inch

mm

inch

mm

A

66

1676

71.57

1818

71.57

1818

79.5

2019

B

159

4039

159.84

4060

159.87

4061

159

4039

C

32.5

826

33.9

861

45.51

1156

62.5

1588

D

18.25

464

25.88

657

24.6

625

18.25

464

E

24.38

619

25

635

25

635

26.5

673

F

18

457

19.29

490

19.29

490

18

457

G

25

635

27.17

690

27.17

690

21.5

546

H

48

1219

49.75

1264

47.1

1196

48

1219

I

16

406

16

406

16

406

16

406

J

9.75

248

9.75

248

9.75

248

8.5

216

K

37.25

946

45.5

1156

41.93

1065

46.5

1181

ducing this clearance is not recommended. You must allow space around the machine for mainte-

nance.

3.3.2

Floor Requirements

The installation site must have flooring capable of supporting the weight of the machine with-

out flexing. Consult the general specifications in the previous section for specific details on the

machine’s weight and other technical specifications. No special foundation, grouting, or anchor-

ing is required by the manufacturer, but some shimming may be required so that the machine is

completely level. Always follow local codes when performing a machinery installation. It is the

responsibility of the installer to be familiar with the requirements of local codes.

3.3.3

Gas Requirements

The ironer requires a significant gas service capable of providing the volume and pressure needed

to achieve the BTU rating of the particular machine. Typical gas pressure ranges from 12 inches

water column to 2 PSI with ratings up to 825,000 BTU. Refer to the previous section for gas con-

nection sizing, gas pressure requirements and BTU ratings.

3.3.4

Exhaust Duct Requirements

A short run of exhaust vent ducting is required and must be procured locally. Adequate ventilation

is required and must meet all local codes. Refer to the previous section for airflows and other

11