Xpres Subli-Print Epson 1290: Bulk Feed (XP5019 - Version 4) installation instructions User Manual

Page 5

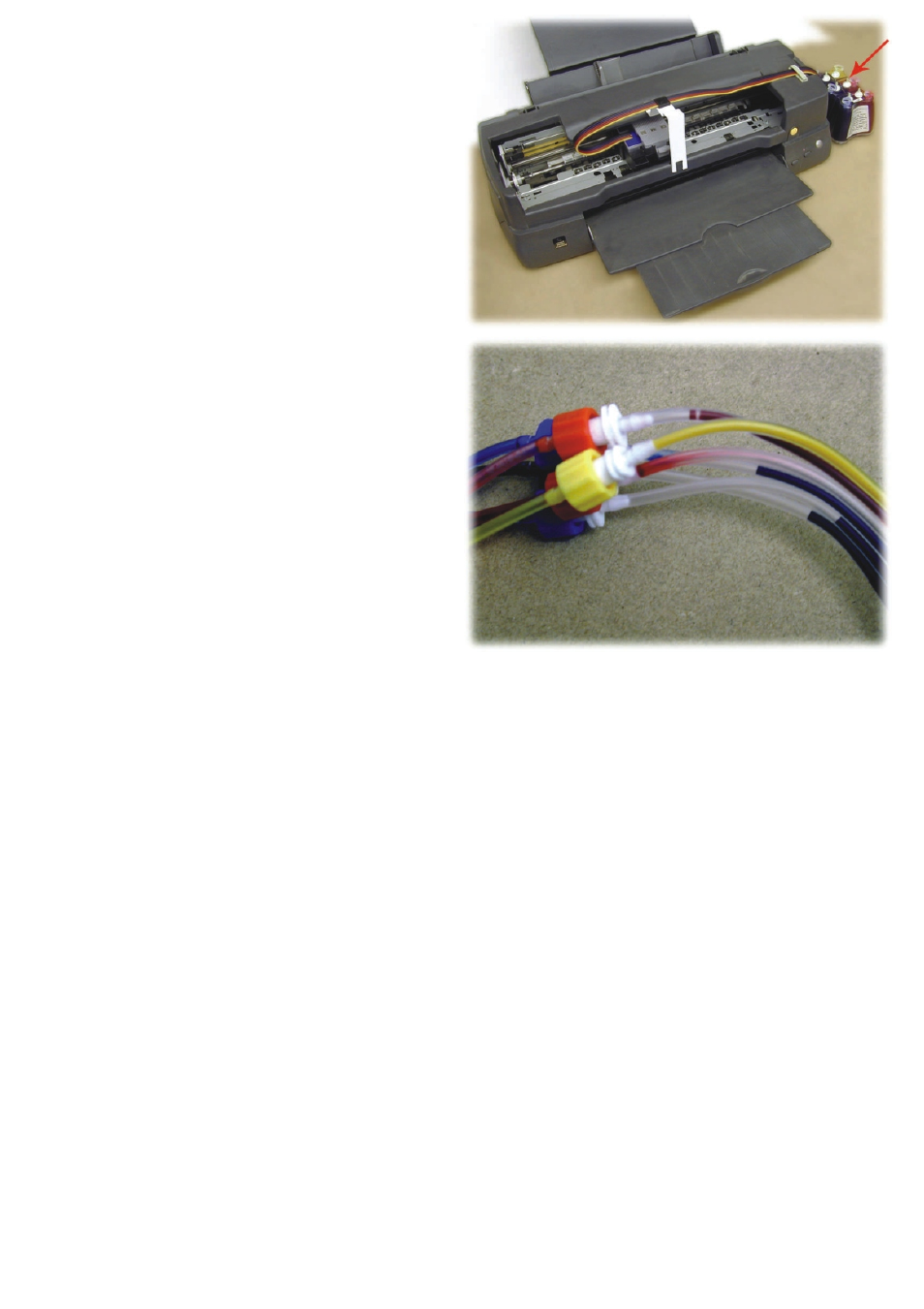

Fit the excess tube into the small tube

clamp so it does not interfere with the

printheads movements and fit the air

filters into the small hole on the bottles

(

arrowed

)

Plug the printer back into the mains

supply and the printhead will move back

and forth then perform it’s initial ink

charge.

During this ink charge you should see the

ink flowing through the tubes near the

connectors.

The air you may see in the tubes is not

significant and will not affect the operation of

the system in any way.

After the ink charge print out a nozzle check to see if all the colours are printing correctly. If they are, you

are set to go. If not perform a head clean and test the nozzle check again. You s hould see an improvement

on the next nozzle check. If still not perfect you can perform one or two more head cleans (

do not overdo

this exercise

) until you get a good nozzle check.

Occasionally a printer will stubbornly refuse to print a perfect nozzle check after a couple of head cleans.

There can be a number of reasons for this including the fitting of a dye sublimation system for the first

time or a printer being left for a long time without running any prints.

One way of curing this is to force the printer into a ‘power clean’. To do this you will need to send a good

size image to the printer (use an 8” x 10” [20cm x 25cm]) and when about a quarter of the image has

printed, press (and hold down) the ink button on your printer (the one at the side of the power button).

After you have held this button down for 5 or more seconds the printer will pause printing, perform a head

clean and then carry on printing where it left off (it is not necessary to waste transfer paper on this exer-

cise).

You may have to hold this button down again 1-2 more times during the print – you should be able to see

if the banding is disappearing. If you have had to press the button for the 3

rd

time the printer will now per-

form a ‘power clean’. Print a nozzle check immediately after this. If this nozzle check is good, you are set

to go. If there are still problems with it leave the printer to settle for at least half an hour before printing

out another nozzle check.

If there has still been no improvement you can carry out this ‘power clean’ exercise one more time includ-

ing the half an hour settling time afterwards.

Page 5