Doming – Xpres Easy Dome User Manual

Page 6

Main Points When Doming

•

ensure that the working area is well ventilated, clean & free of dust.

•

ensure that the working area is level.

•

ensure temperatures are kept consistent at all times during the Doming process. Xpres easy Dome Resin operates best

between 17°c - 25°c, and Humidity of 40%.

6

Doming

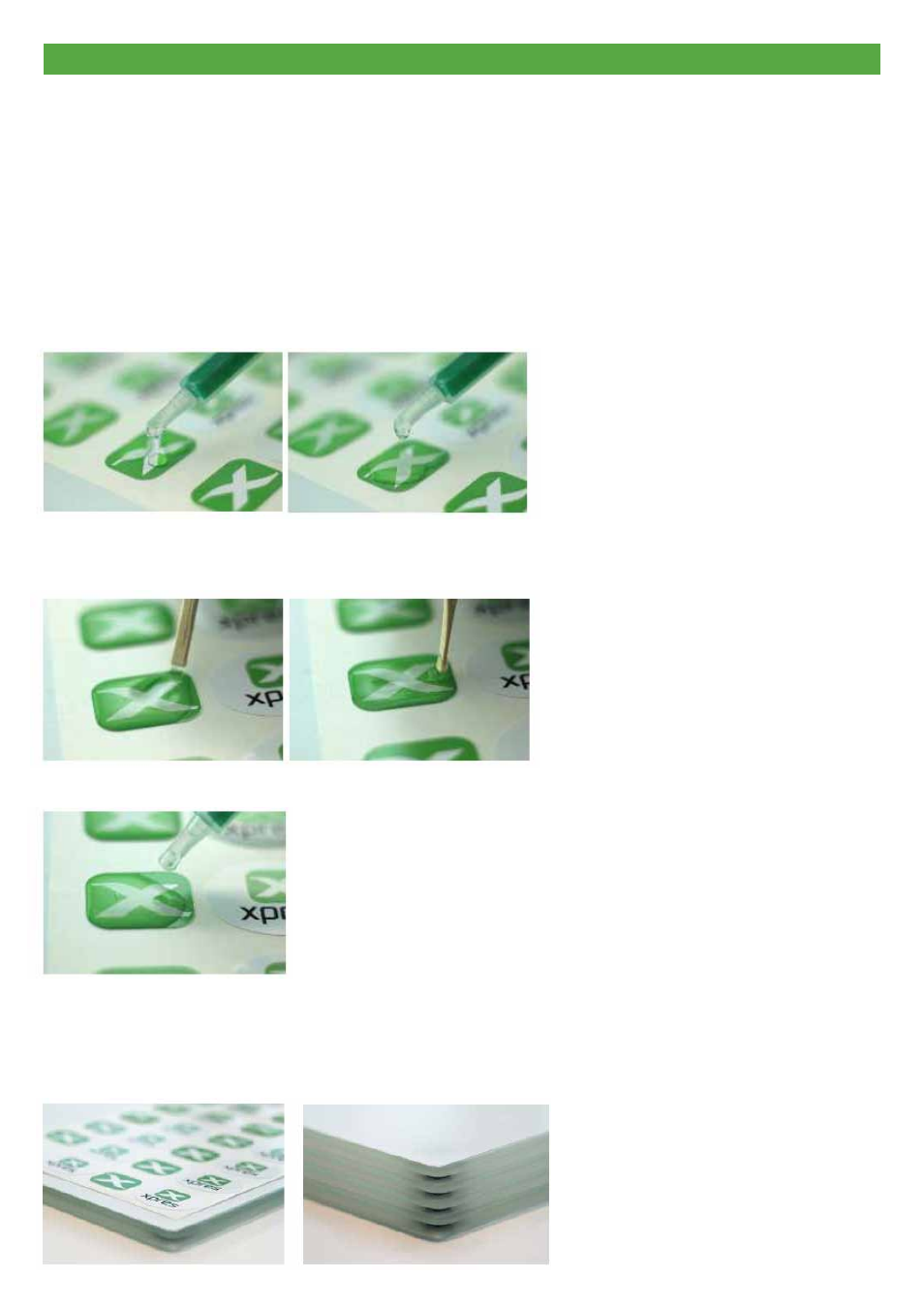

Applying Resin

Before applying resin, it is important to hold the cartridge at a 45° upright angle and dispose of the first 1 - 2 grams of resin.

This is to allow any air bubbles within the cartridge to be released.

Apply resin to the transfer by pulling the Applicator Gun trigger at a constant, slow, comfortable rate. Good practise is to

apply slightly less resin than is anticipated. The resin will flow to the edges of the transfer by itself.

occasionally the resin needs encouragement to fill the transfer. If the resin has not covered the transfer fully within 5-6

minutes you can use your Repair stick (break in to two parts) to drag small amounts of resin into the corners and other places

the resin has not reached. This will apply more to detailed designs where the resin needs prompting in to certain areas.

After 5 - 10 minutes the transfer should be fully covered. If it is not, consider applying additional Resin.

once the resin has spread across the transfers fully, the domed transfer can be left to cure. The finished domed transfer

should be left approximately 12 - 16 hours to cure fully. Depending on the room temperature curing times can vary from 12

hours upwards. once cured the domed transfer is ready to be handled.

The Doming Glass Trays can be stacked. Always place a glass layer above your domed transfers to help prevent any dust

settling in the resin as the dome cures.