Set up – Xpres Easy Dome User Manual

Page 5

5

Preparing Transfers for Doming

Transfers should be rounded at the corners, and the corner angle

no less than 90 degrees. The ‘corner radius’ should be at least

3mm.

Although right angled corners can be domed when care is taken,

it is recommended that all relevant corners need to be curved.

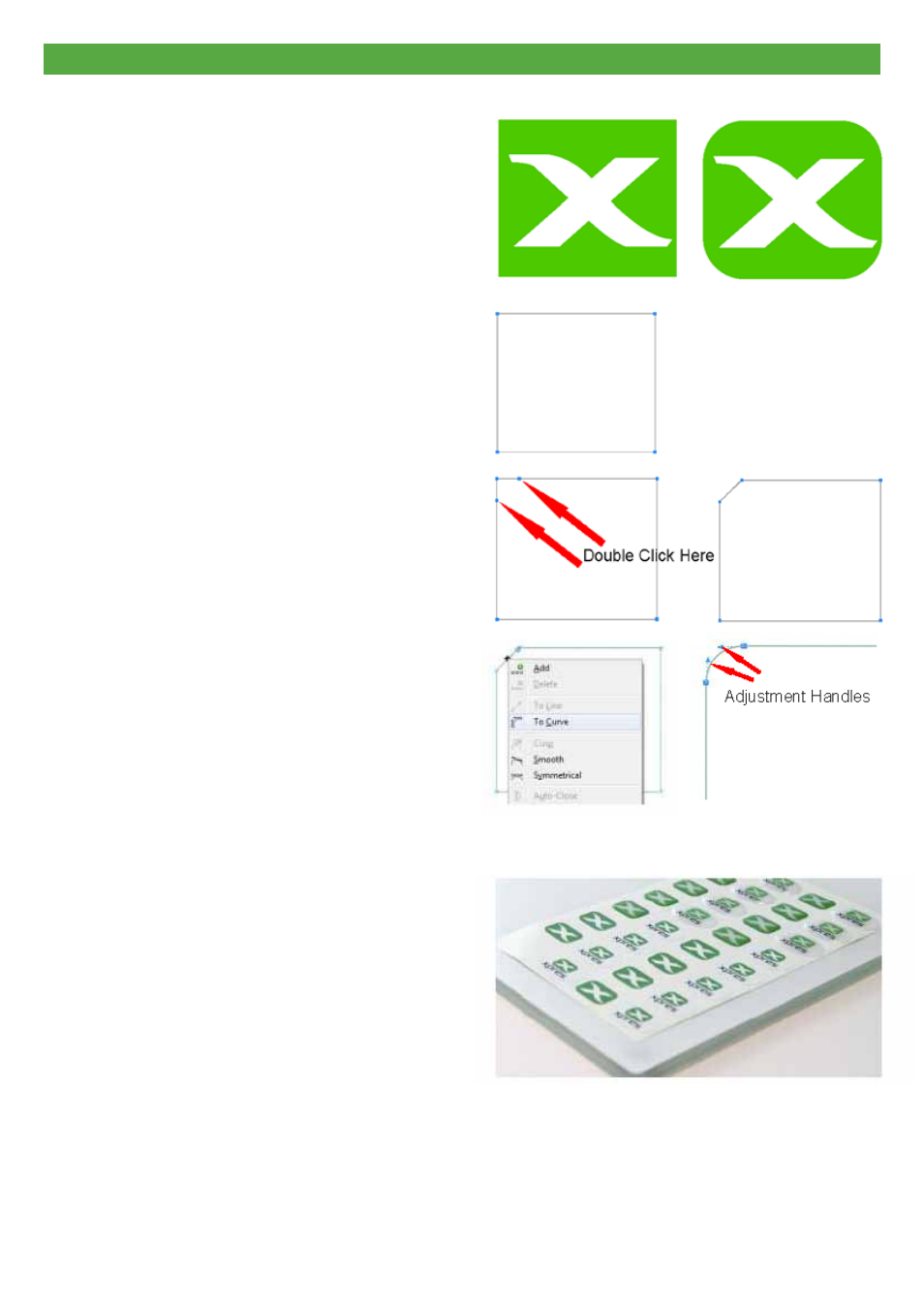

The example right shows a design where the corners have been

adjusted. If left as shown in the ‘before’ diagram the Xpres easy

Dome Resin could over-spill.

Curving Angles:

To curve the corners on a design ready to cut, select your shape

Tool within corelDRAW and click on your design or cutline. You

will see the nodes appear (Blue) - these nodes can be deleted,

moved, added etc as needed (you may need to convert the

object to curves if the nodes do not show). The example right

shows a square cutline with the nodes visible which we can edit.

Using the shape Tool, double click on the cut line either side of

the node at the point we are trying to remove, this will add two

new nodes (Diagram 1). We can then double click on the original

node which made the point of the original angle, this node will

now be deleted and you will see the example right (diagram 2).

now Right click on the line directly between the two nodes

you have created with the shape Tool, and select ‘to curve’ as

shown right.

With the shape Tool you can now Left click on the cutline

between the two nodes previously added, whilst holding the

Left click down drag the cursor outwards, you will see that this

creates your curve, which you can fine tune with the Adjustment

Handles.

continue this process around the design on internal and external

angles until the cutline has no sharp points - the cutline is now

ready for output.

Positioning Transfers:

once cut, weed away the excess film and place the transfers

on to a Doming Glass Tray as shown below. Make sure that

the transfers lay flat on the surface of the glass (no air bubbles

underneath), and also make sure that the surface is level, we

recommend using a spirit level - this is important to create even

resin thickness over a transfer and also to reduce over-spill.

Mounting spray is recommended to keep the transfers flat on

the surface of the glass.

Tip:

We recommend that transfers are produced with at least a

5mm gap between logos/transfers. This is to help prevent any

resin over-spills having a knock-on effect in to the next

logo/transfer, reducing waste.

note:

one 50g resin cartridge will be able to dome

approximately 50 25 x 25mm (1 inch)2 transfers.

Set up

Before

After

Diagram 1

Diagram 2