Vetter Pipe sealing bags and bypass bags FS User Manual

Page 9

Page 9/18

9

Secure the sealing bag with a securing line in order to avoid

the bag slipping back when deflated.

9

The support structure should be made so that the sealing bag

can be supported over a large area.

9

Leave the shaft and/or pipeline.

9

Make certain that no staff remain in the area of danger.

9

Inflate the sealing bag to the permitted maximum operating

pressure from a safe position

There is a danger of the bag catapulting outwards. The pressure

or water column must be completely reduced within the pipeline

before the support structure is removed. Otherwise the sealing

bag could catapult outwards. After completion of the work, pres-

sure reduction is to be carried out via the inflation hose (ventila-

tion nipple) or the controller (pressure reduction via the knurled

screw of the safety valve). Generally this must be made outside

the pipeline or shaft.

9

If the water has completely flowed out of the shaft/pipeline

then release the compressed air out of the bag.

9

Now remove the support structure and take the bag out of

the shaft/pipeline.

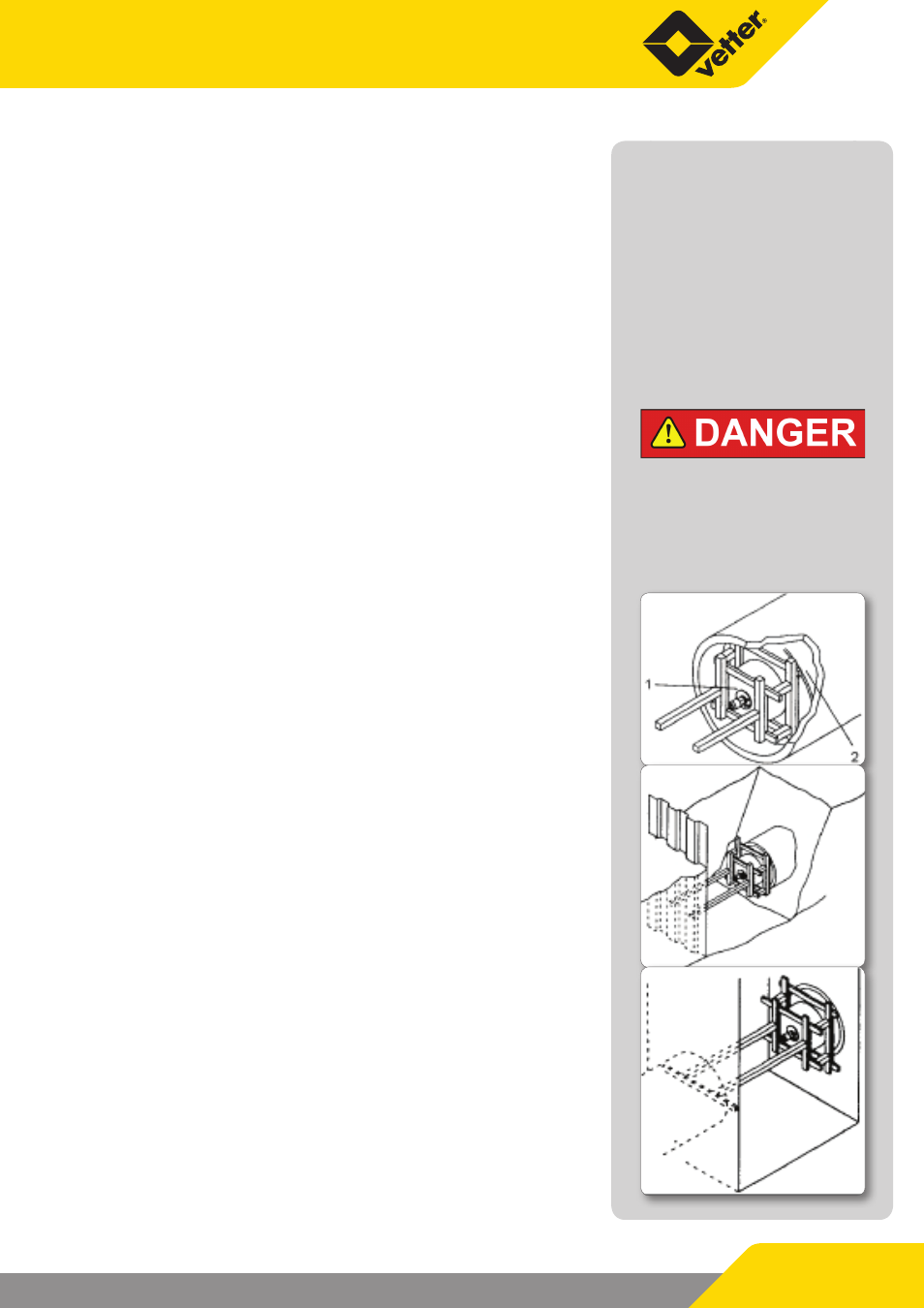

4.2

Support structure

The type of support structure depends on the structural factors in

the pipe, the pipe itself and the counter-pressure to be expected.

The following support possibilities are only drawing diagrams and

are given as examples.

General details of support

(presented as a diagram)

1 Bag centre

2 Inflatable bag sleeve

Support suggestion for a ditch

(presented as a diagram)

Support suggestion for a street inlet shaft

(presented as a diagram)