Vetter Pipe sealing bags and bypass bags FS User Manual

Page 11

Page 11/18

4.4

Emptying the pipeline

9

It is to be ensured that nobody remains in the shaft or pipe

before emptying the pipeline.

9

Empty the secured sealing bag via the controller so the dam-

med liquid is able to slowly flow pass the sealing bag and sup-

port structure.

9

The support structure or the securing device must only be re-

moved when the pipeline is completely empty.

9

Check the applied bag and its accessories for completeness,

perfect condition and function.

The support structure of a pipeline under pressure must never be

removed. Pipe sealing- and/or bypass bags could suddenly cata-

pult outwards.

4.5

Construction of a temporary bypass

Persons can be endangered by sudden inrushes of water, therefo-

re an additional pipe sealing bag (2) must be installed in order to

ensure the safety of the construction area. The safety regulations

and information issued by the corresponding authorities are to

be observed!

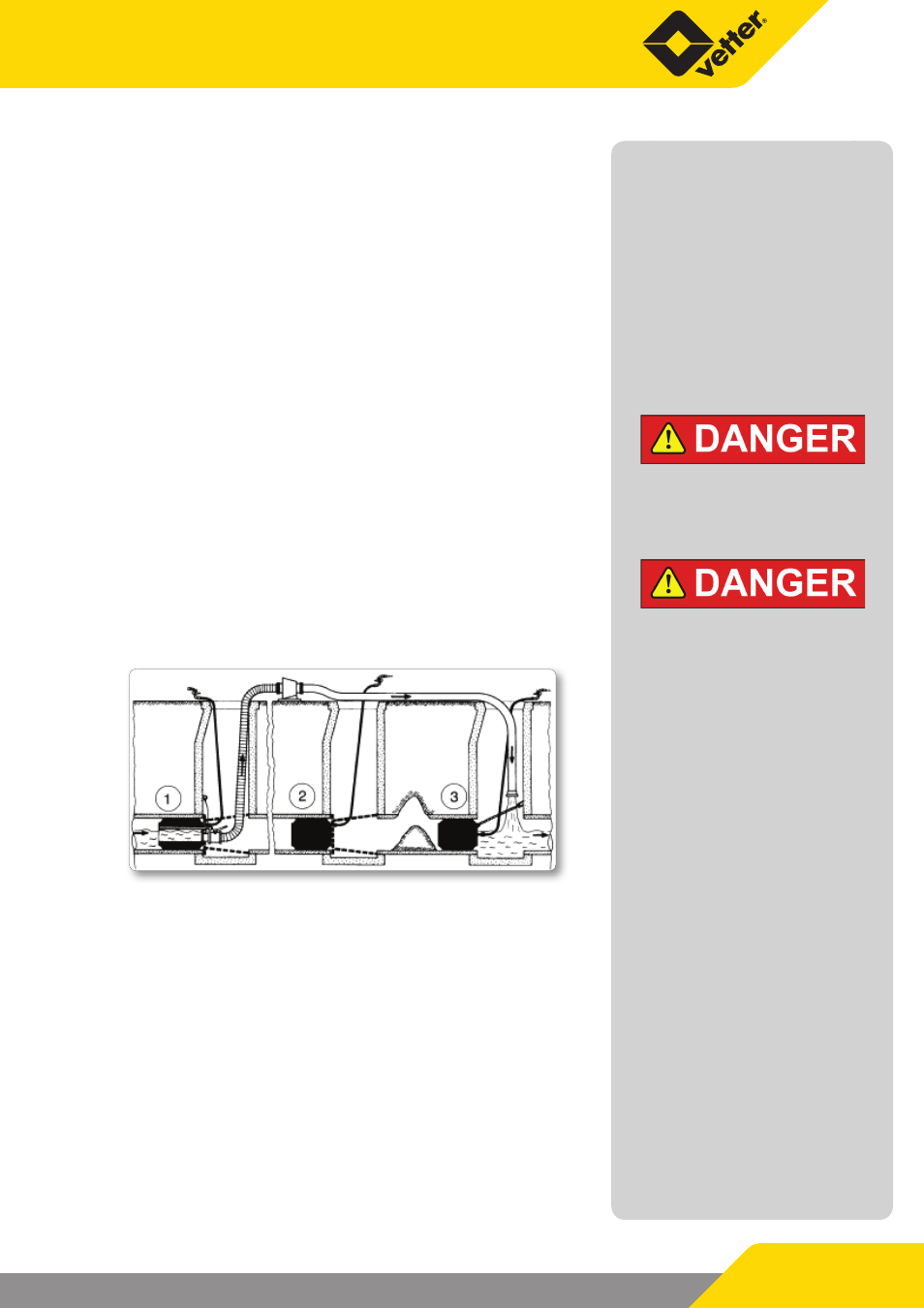

Construction of a temporary bypass

(schematic diagram)

9

Due to presentation reasons, the support structure and secu-

ring lines are schematically presented and simplified.

9

Fit the corresponding bypass adapter in order to bypass the

sealing bag. Insert the bypass bag (1) at the top of the const-

ruction site into the pipe.

9

Support the bag according to shape.

9

Ensure the bag additionally with a securing line.

9

Connect the Storz coupling (A resp. B) to the suction pump

installed above ground via the suction hose.

9

Make certain that the level of dammed liquid does not exceed

5m water column.

9

Connect a hose to the pump on the pressure side and position

it into the pipe system at the back of the construction site.

9

Insert an additional pipe sealing bag (3) in order to avoid a

backflow into the construction area.