Pipe sealing- and bypass bags, Material and resistance charts, 1 material chart – Vetter Pipe sealing bags and bypass bags FS User Manual

Page 16: 2 temperature resistance

Page 16/18

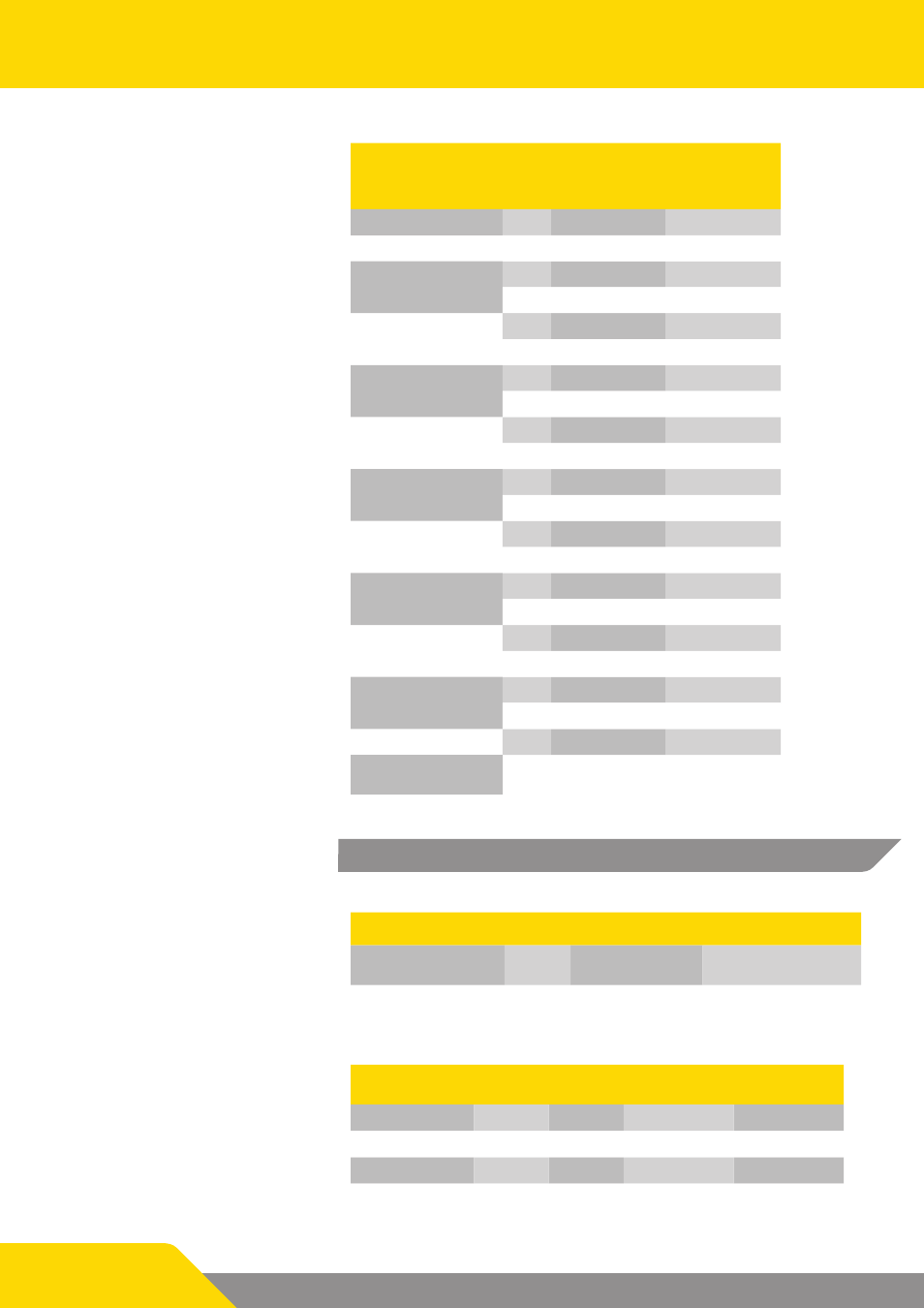

Pipe Sealing- and Bypass Bags

Art. No.

1483001600

1483001000

Art. No. with integra-

ted inflation hose

1483001300

1483000500

Description

BK 50/120 FS

BK 80/140 FS

Bypass size

4“

4“

Pipe diameter

cm

50 - 120

80 - 140

inch

20 - 47

32 - 55

Diameter

cm

45

78,5

inch

17,72

30,91

Operating pressure

bar

1,5

1,5

psi

21,75

21,75

Test pressure

bar

1,95

1,95

psi

28,3

28,3

Test counter-pressure

m WS

5

5

psi

7,25

7,25

Cylinder length

cm

92

181

inch

36,22

71,26

Total length

cm

94

193

inch

37

75,98

Nominal capacity

l

568

1230

cu.ft.

20,06

43,44

Air requirement

l

1420

3075

cu.ft.

50,1

108,6

Weight

kg

52,2

69,0

Weight with integrated

inflation hose, 10 m

kg

55,0

74,6

All rights reserved for technical changes within the scope of product improve-

ment.

8.

Material and resistance charts

8.1

Material chart

Products

Material Support material

Manufacturing process

Pipe sealing bags 1.5 bar

for fire services

CR

Nylon cord/Aramide Hot vulcanised

Bypass bags 1.5 bar for

fire services

CR

Nylon cord/Aramide Hot vulcanised

8.2

Temperature resistance

Products

Cold

resistance

Cold

flexibility

Heat resistance

long term

Heat resistance

short term

Hot vulcanised

- 40° C

- 20° C

+ 90° C

+ 115° C

Cold vulcanised

- 40° C

- 20° C

+ 70° C

+ 85° C

Rubber hoses

- 40° C

- 30° C

+ 90° C

Controllers

- 20° C

+ 50° C