Vetter leak sealers – Vetter Leak sealers User Manual

Page 16

2

1

3

4

5

3

2

1

3

4

5

Vetter Leak Sealers

Page 16/39

9

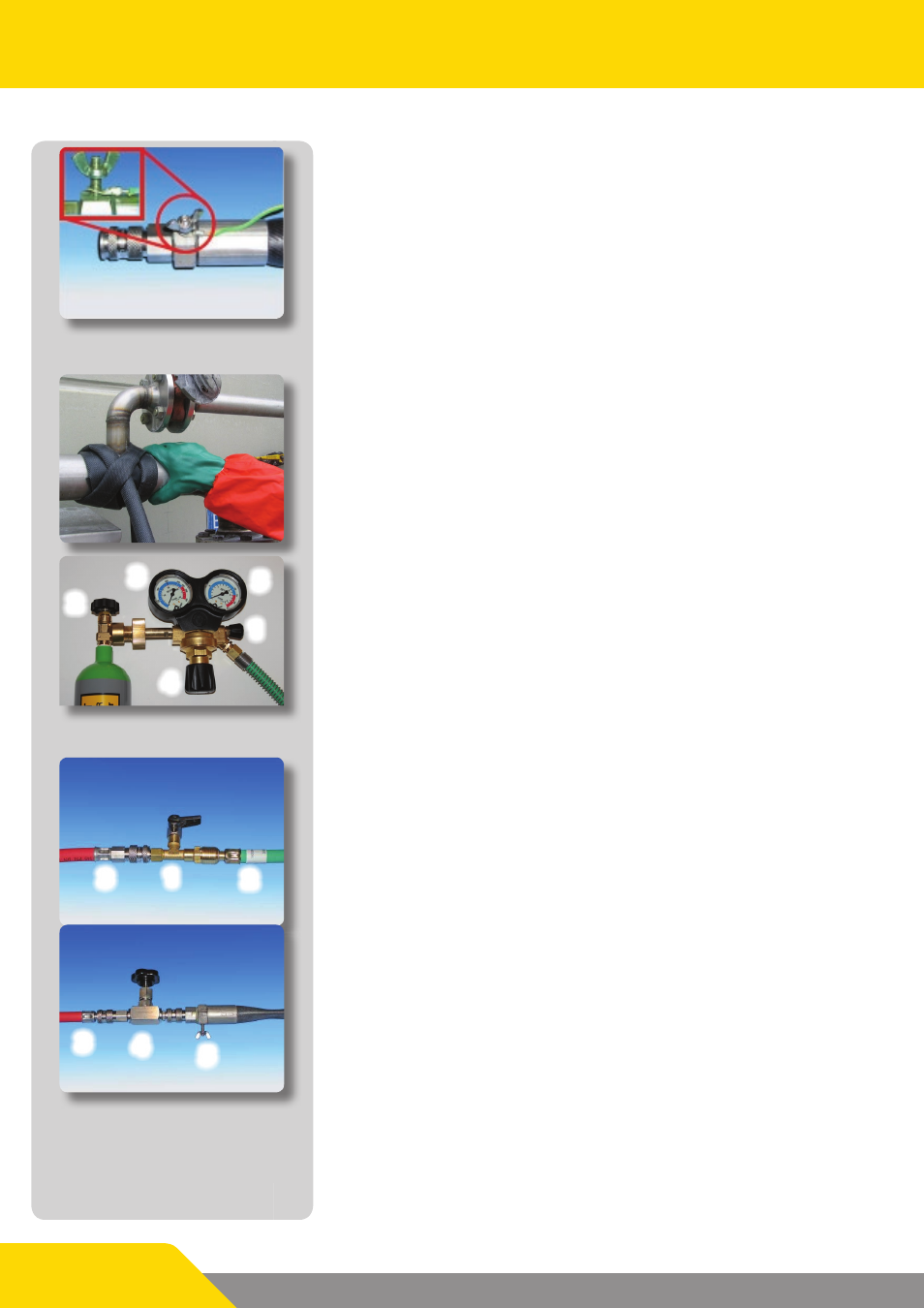

Before use, check to see whether the high pressure leak sealing

system is resistant against hazardous materials.

9

Wear specified protective clothing necessary for operation

6.4

Operation instructions

9

Select the sealing hose most suitable for the leak, respectively

lay a sealing plate (EODM, NBR, glass fibre reinforced plastic)

underneath.

9

Entwine the pipe to be sealed so that the first point of the

sealing hose completely covers the leak position.

9

Feed through, as shown below, one layer under the sealing

hose.

After this connect the inflation device as follows:

9

Connect the pressure regulator to the compressed air bottle.

9

Close the outlet valve (1) by turning clockwise.

9

Open the valve on the bottle (2).

9

The pre-pressure manometer indicates the pressure in the

bottle (3).

9

Adjust the backpressure on the regulator (4) to a maximum

of 10 bar.

9

The reduced pressure is indicated on the backpressure mano-

meter (5).

9

Connect the ventilation valve (1) to the connection hose (2) of

the pressure regulator.

9

Connect the ventilation valve (1) to the red inflation hose (3).

9

Close the ventilation valve!

9

Connect the red inflation hose (3) to the closed inflation valve

(4) and couple to the sealing hose (5).

9

In order to inflate the sealing hose, open the outlet valve on

the pressure regulator by turning counter-clockwise.

9

Now carefully open the inflation valve and inflate the sealing

hose until the damaged point is just sealed.

9

Close the inflation valve.

9

In order to remove the inflation device, close the outlet valve

on the pressure regulator and open the ventilation valve. The

inflation hose, which is now not under pressure, can be un-

coupled from the inflation valve without any difficulty.

9

The connected high pressure leak sealing system is to be con-

tinually monitored.

9

The damaged pipeline can now be switched off without dif-

ficulty and can be repaired after emptying.