4 description of the product – Vetter Mini Lifting bags 8 bar (116 psi) User Manual

Page 7

Page 6/19

2.4 Description of the product

Vetter Mini-Lifting Bags are made by hand from high quality raw

materials so that after completion, a seamless bag is produced.

The semi-finished product is vulcanized under the influence of

pressure and temperature and by doing this the individual layers

bond to form an elastomer body. After production has been fina-

lized, each Mini-Lifting Bag is subjected to a plant acceptance test

within the scope of quality assurance.

Material of the Mini-Lifting Bags: CR/Aramide, hot vulcanized

Temperature resistance of Mini-Lifting Bags:

Cold resistance

-40 °C

Cold flexible

-20 °C

Heat resistance long-term

+90 °C

Heat resistance short-term

+115 °C

The aramide layer on the Mini-Lifting Bag

can be damaged by damage made to the

bag surface, e.g. cuts, cracks, punctures or

by the effects of ozone.

Therefore with a visual check after every operation, special atten-

tion is to be made to the following types of damage:

9

Damage by separation

9

Damage by cuts

9

Damage by punctures

9

Damage by heat and chemicals

Danger of bursting! If, when carrying out the

check, this type of damage is determined

then the bag is to be immediately taken

out of service. Repair is not possible.

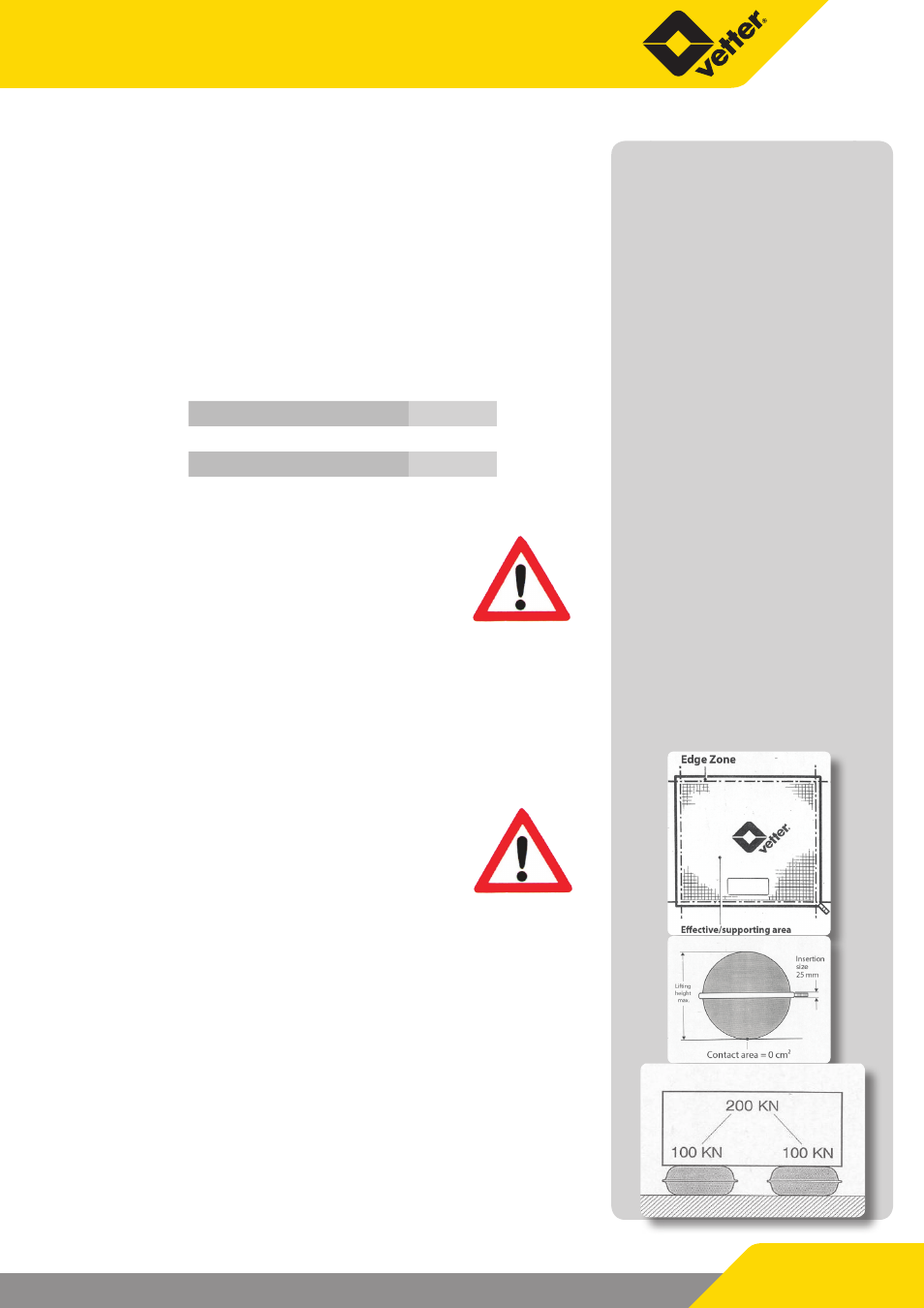

In order to use the maximum lifting power, the total effective area,

i.e. the total area minus the edge area, must be completely under

the load to be lifted and that the bag must be taken to the maxi-

mum permitted operating pressure.

The bag develops a spherical shape (with rectangular or square

base) as the lift height increases. This is the reason why the con-

tact area with the load decreases until at a max. bag curvature this

will be almost zero. The largest lift height of the Mini-Lifting Bag

will only be reached in the unloaded state.

In case the lifting power produced by the Mini-Lifting Bag is not

sufficient, depending on the lift height, then a number of Mini-

Lifting Bags can be placed next to each other.