Diagram a diagram b – Tjernlund COP2 Constant Operating Pressure Exhaust Control 8504208 User Manual

Page 4

3

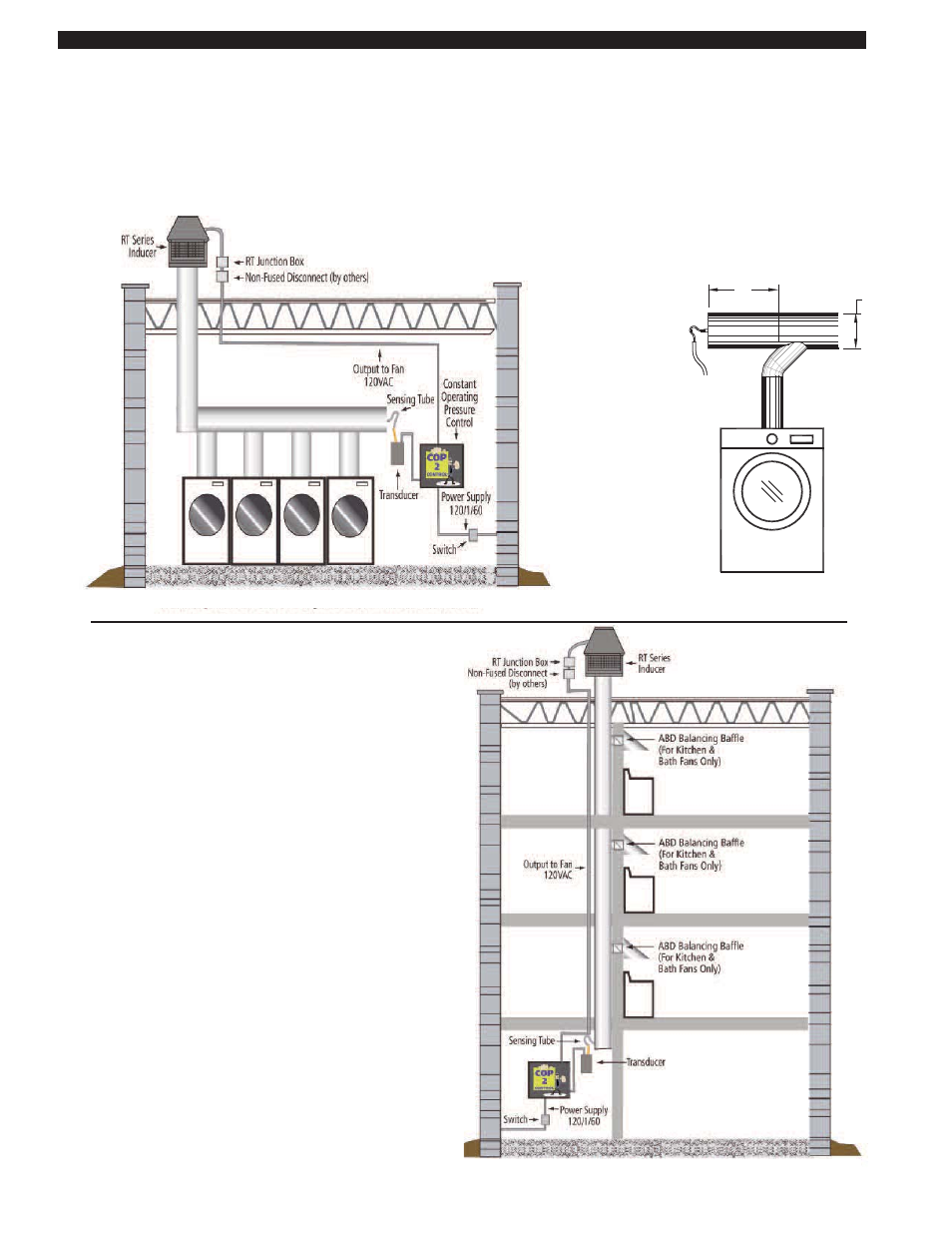

PRESSURE SENSING TUBE LOCATION

MULTIPLE DRYERS JOINED IN A COMMON HORIZONTAL DUCT

The sensing tube should be installed in the vent cap of a tee or at the rear of a common exhaust manifold, in back of the vent con-

nector that is farthest from the RT-Series Fan. The tee is necessary so that only static pressure is measured, (See Diagram A). If

the pressure sensing tube is installed in the side of a duct it will also measure velocity pressure, giving an incorrect signal back to

the COP2 Control. If mounting on the side of the duct is unavoidable, the sensing tube should be flush to the interior wall of the

duct. Avoid sampling near or in elbows. Duct connections should be sealed to prevent leakage or entrainment. Installer must pro-

vide access for lint clean out.

MULTIPLE DRYERS, KITCHEN OR BATH FANS EXHAUSTED

INTO A COMMON VERTICAL CHASE

The sensing tube should be installed to sample the chase pres-

sure at a point below the lowest duct connection but above any

point in the clean out that may accumulate moisture or lint. If

sampling pressure in the side of a chase, the sensing tube end

should be flush to the interior wall of the chase, (See Diagram B).

Duct connections should be sealed to prevent leakage or entrain-

ment of air. Installer must provide access for lint clean out.

BEHIND THE DRYER FURTHEST FROM INDUCER

BE LOCATED TWICE THE MANIFOLD DIAMETER

IF POSSIBLE, THE SENSING TUBE SHOULD

D

2D

DRYER FURTHEST

FIGURE 8054008 4/14/11

FROM THE INDUCER

MINIMUM

XCOP1

SENSING

TUBING TO

DIAGRAM A

DIAGRAM B

Chase Exhaust for Kitchens & Baths or Dryers

Multiple Clothes Dryers Common Vented

DRYER FURTHEST

FROM ROOFTOP FAN