Troubleshooting – Symtech VFX 1 User Manual

Page 19

18

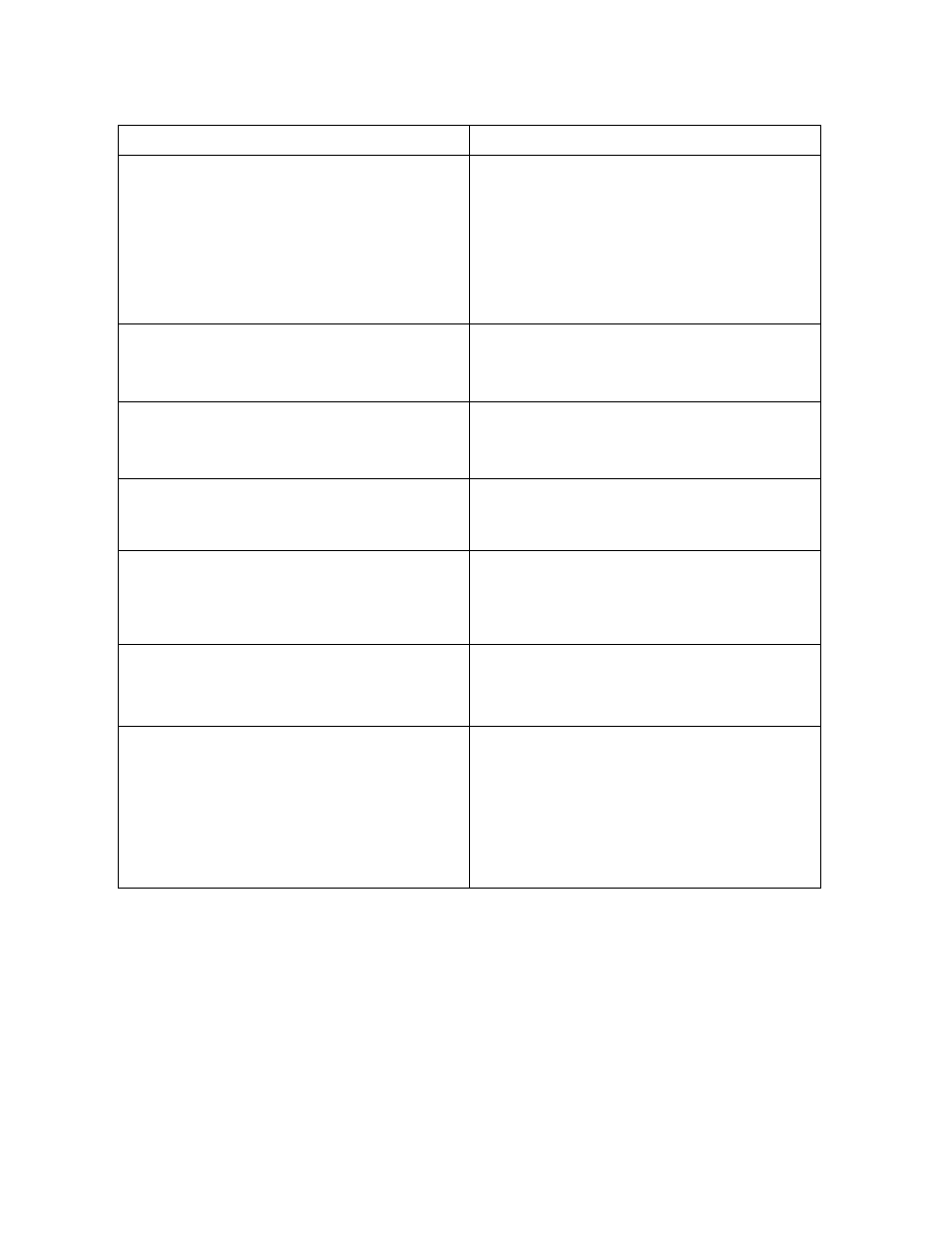

Troubleshooting

PROBLEM

SOLUTION

Vacuum speed or level is reduced

- Inadequate air supply. Must maintain 70psi

minimum throughout service.

- Air powered vacuum venturi has become clogged

with debris from dirty air supply.

Please contact Symtech for service procedures.

- Leak in the unit. Please contact Symtech

Corporation for service procedures.

Removal of coolant stops prematurely (before all

removable coolant is removed)

- Cone has become dislodged or unseated from

radiator or Remote Reservoir tank neck. Check that

cone is properly seated and vacuum level of at least

20inHg can be obtained

Vacuum level of at least 20inHg is obtained but no

coolant is removed

- Cone may be “bottomed out” on shallow radiator or

Remote Reservoir tank neck preventing coolant

flow. Cone may need to be trimmed back to

prevent “bottoming out”

Used coolant tank sight gauge is too dirty to view

level

- Sight gauge can be restored to new by emptying

used coolant tank and replacing sight gauge with new

17.5” X 3/8 O.D. length of new vinyl tube. Available

at Symtech.

Used coolant is leaking from bottom of unit

- Used coolant tank has been over-filled and used

coolant is escaping through relief valve of tank.

- Possible leak inside unit – contact Symtech

Corporation for service procedures

New coolant did not or can not adequately refill

vehicle

- New coolant tank level or supply is empty or

coupler disconnected. Check level and replenish if

necessary. Check coupler for proper connection to

new coolant tank.

Coolant exchange in FLUSH mode does not occur.

- Recheck all connections, control panel valve

positions, and flow control valve positions and

retry. See pages 11 and 12

- Reverse RED/NEW and BLACK/USED hose

connections and retry. See pages 11 and 12

- Start vehicle allowing it to reach normal operating

temperature and retry. See pages 11 and 12

For more information and Frequently Asked Questions, and to watch demo videos, please

go to…. www.symtechcorp.net