Blue, Reverse flush exchange – Symtech VFX 1 User Manual

Page 12

11

REVERSE FLUSH EXCHANGE (

BLUE

)

Connection Possibilities

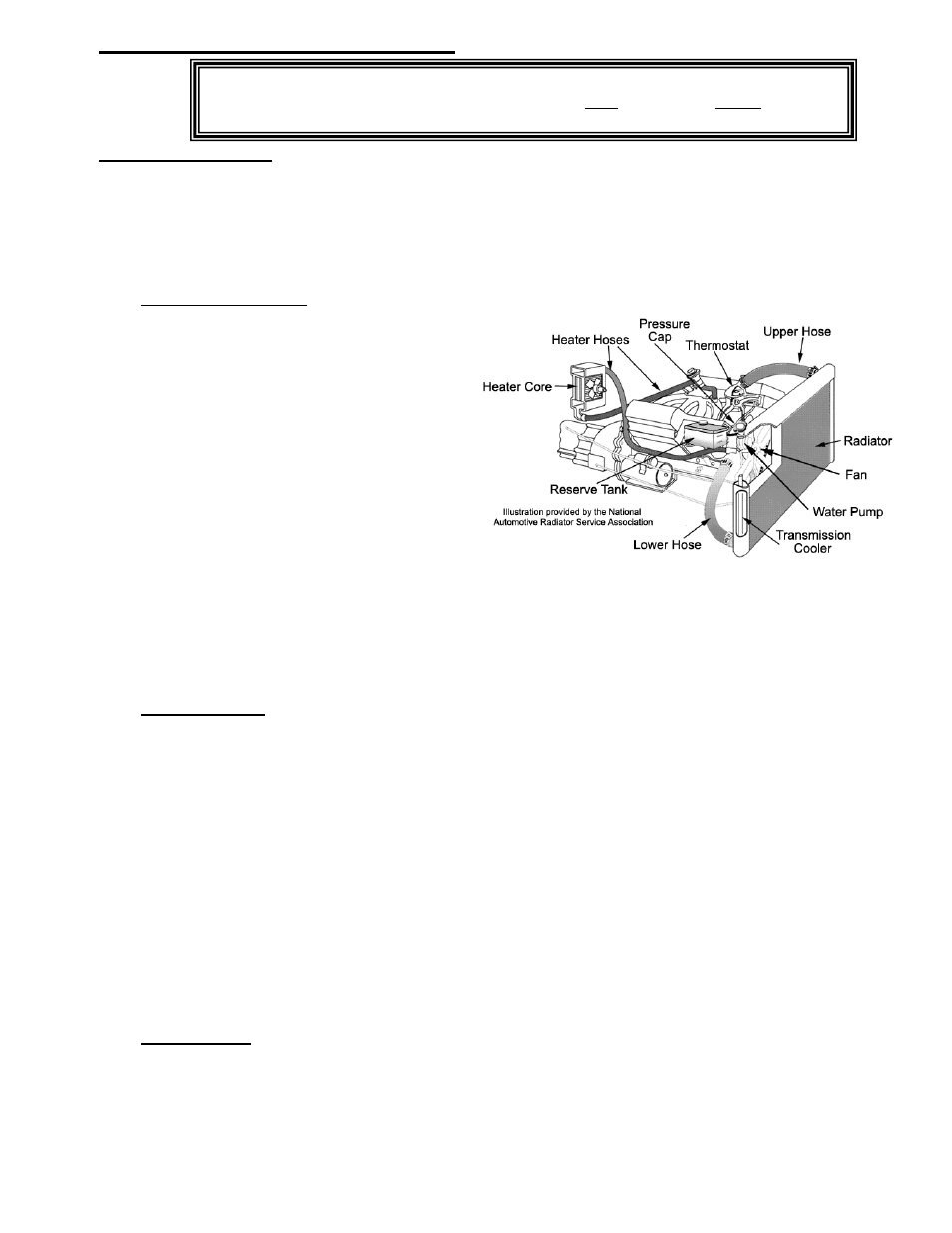

Reverse Flush exchanges entail opening the cooling system up at either end of the upper radiator hose connection via

step adapters and adapter hoses of the appropriate size, connect the VFX 1 new and used coolant lines to the installed

adapters and flush the used coolant out via new coolant being introduced. There are three possible connection scenarios

to achieve the proper flow direction to successfully perform the exchange and each scenario must be tried in the

following order:

1.

TRADITIONAL FLOW - Most vehicles have

traditional coolant flow – coolant flows downward

through the radiator, pulled by the water pump

through the lower radiator hose, pushed through the

engine block water jacket, upward through the heads

and intake, out the thermostat (if engine is to normal

operating temperature) and back to the radiator to

repeat the process via upper radiator hose. Please

refer to diagram.

To Reverse Flush this type system, the upper radiator

hose is disconnected, and new coolant is introduced

via adapters and adapter hoses against the “backside”

of the thermostat. The pressure of the new coolant

forces open the thermostat and flows backwards from

normal flow “pushing” the used coolant and debris

through the cooling system and out the upper radiator

hose into the used fluid tank of the VFX 1.

NOTE: After connecting unit for Traditional Flow, if new coolant pump DOES NOT pulsate and used coolant IS NOT

flowing from radiator to unit, RECHECK all connections, control panel valves, and flow control valves for

correctness and RETRY. IF problem persists, the vehicle’s cooling system is a REVERSE FLOW SYSTEM

or THE THERMOSTAT WILL NOT OPEN FROM THE BACK SIDE.

2.

REVERSE FLOW – Reverse Flow cooling systems circulate in the opposite direction of traditional systems,

because the thermostat is located in the bottom of the engine block. This means coolant flows up through the

radiator, through the upper radiator hose connection, into the top of the engine block, downward through the

engine block, through the thermostat (if the engine is at operating temperature), and back to the lower radiator via

lower radiator hose for re-circulation.

To Reverse Flush these vehicles follow the same procedures as a Traditional Flow flush, LOWER LEVEL,

ADAPTER SET-UP, However reverse the connection of the coolant flow control valves. Connect the

RED/NEW coolant flow control valve to the upper radiator hose adapter and the BLACK/USED coolant

flow control valve connected to the engine block outlet adapter.

PRESSURE TEST, DISCONNECTING, and TOPPING OFF procedures remain the same once the fluid

exchange is complete.

IF Reverse Flow connection is attempted and new coolant pump STILL DOES NOT pulsate and used

coolant IS NOT flowing from engine block to unit, RECHECK all connections, control panel valves, and

flow control valves for correctness and RETRY. IF problem persists, refer to third connection procedure

below.

3.

THERMOSTAT – The third connection option is utilized only when TRADITIONAL and REVERSE methods

do not work. The third option does not allow for a reverse flush, but does allow a coolant fluid exchange. Follow

the same procedures as a Traditional Flow flush, LOWER LEVEL, ADAPTER SET-UP, however reverse the

connection of the coolant flow control valves as described in Reverse Flow (#2), with the RED/NEW coolant

NOTE: Before Starting, Control Panel Descriptions and Functions must be read and

understood. If vehicle is hot, Pressure Relief procedures must be performed before attempting

a Reverse Flush exchange!! The vehicle remains OFF during the entire Reverse Flush