Symtech VFX 1 User Manual

Page 18

17

Empty Used Coolant

1)

Verify all control panel valves are in neutral position, and flow control

valves at hose ends are OFF.

2)

Connect to clean shop air supply (70-120psi).

3)

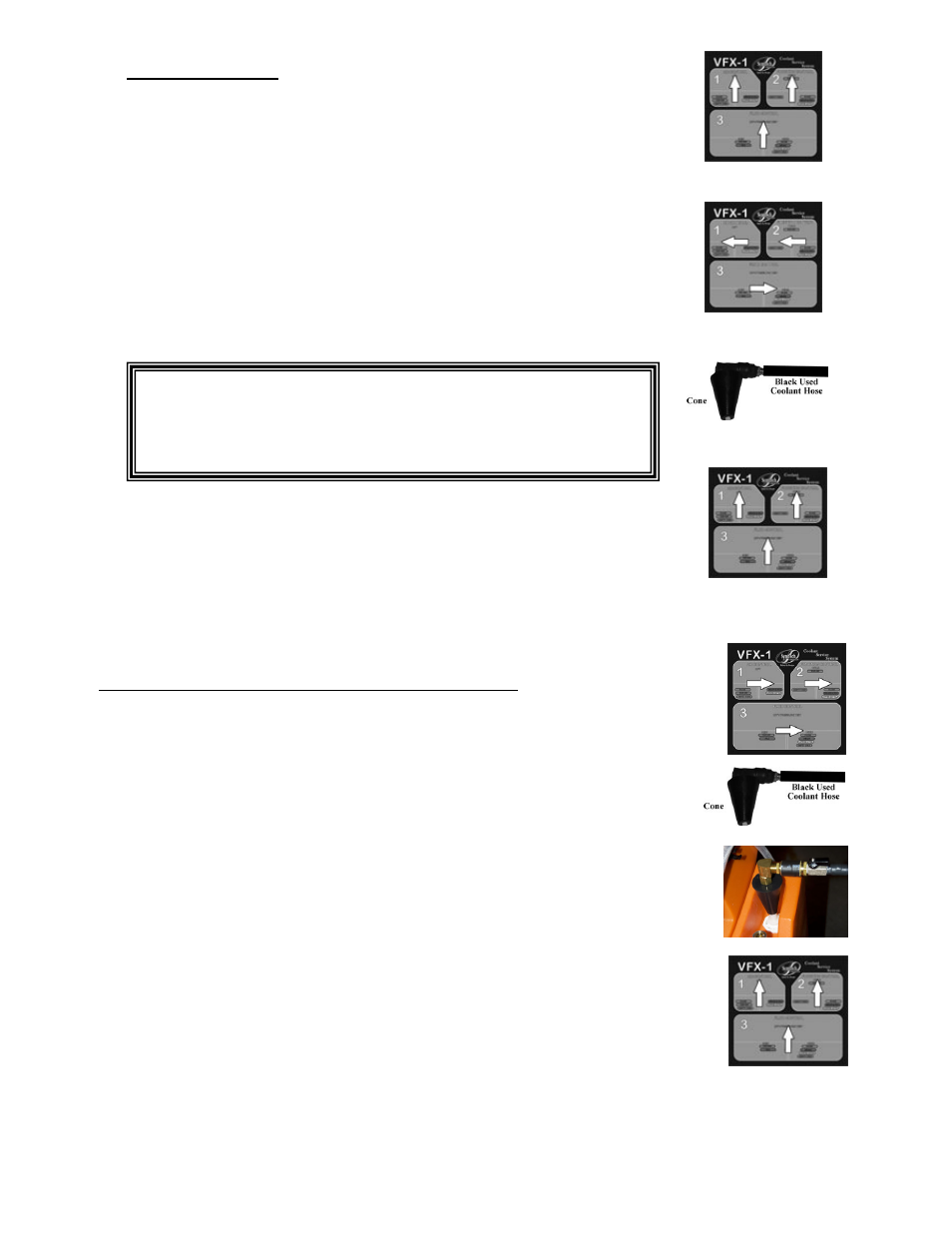

Turn AIR CONTROL valve (#1) and FUNCTION CONTROL valve (#2) to

the left EMPTY USED (

PURPLE

) and FLUID CONTROL valve (#3) to the

right, EMPTY USED (

PURPLE

).

4)

Connect cone assembly to BLACK/USED coolant flow control valve at hose

end. (Fig 3)

5)

Secure cone assembly into used coolant storage vessel. SLOWLY open

BLACK/USED coolant flow control valve.

6)

Close BLACK/USED coolant flow control valve at hose end when all used

coolant drains from unit.

7)

Return all control panel valves to neutral position. (Fig 4)

Empty Tool Storage compartment Waste Fluid Reservoir

1)

Connect clean shop air supply (70-120psi).

2)

Turn

AIR CONTROL

valve (#1), FUNCTION CONTROL valve (#2), and

FLUID CONTROL

Valve (#3) to the right LOWER LEVEL (

YELLOW

)

.

Vacuum will begin to build on the compound gauge. (Fig 1)

3)

Connect extraction cone to BLACK/USED coolant flow control valve.

(Fig 2)

4)

Insert extraction cone over tool storage compartment waste fluid

reservoir tube and remove all used coolant from reservoir. (Fig 3)

5)

Open BLACK/USED coolant flow control valve at hose end.

6)

When used coolant flow ceases, close used coolant flow control valve at hose

end.

7)

Return all control panel valves to correct neutral position, (Fig 4) and

flow control valves at hose ends to off.

Note: The unit uses regulated air pressure (up to 30psi) to empty

the used coolant from the unit. Once the used fluid has been

expelled, the air pressure will cause the BLACK/USED

coolant hose to “jump” or “jerk. Properly secure the hose to

prevent spills.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 1

Figure 2

Figure 3

Figure 4