Origin Live Building a turntable almost from scratch User Manual

Page 17

17

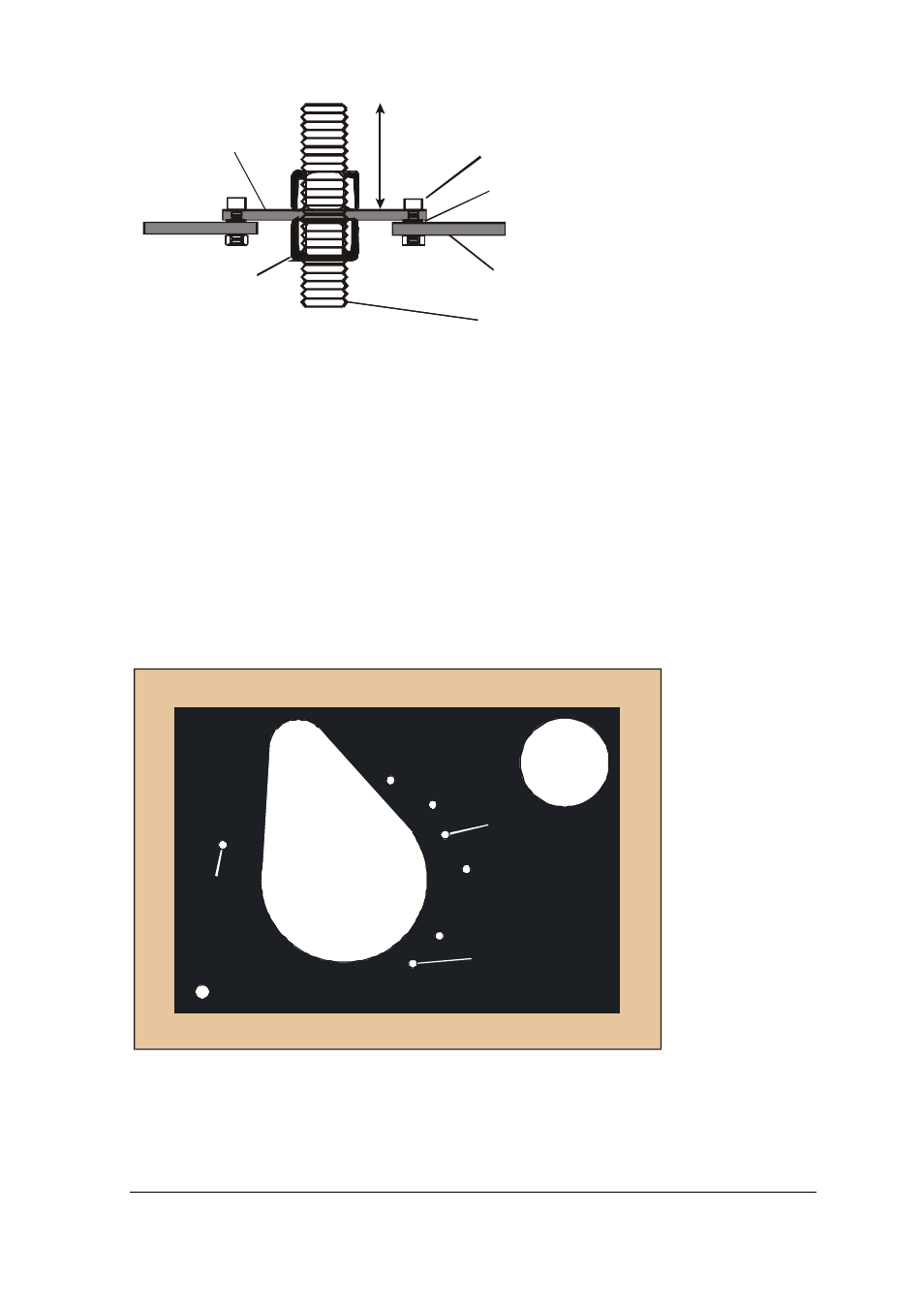

Diagram showing bearing house fastening arrangement

Bearing House

Allen bolt

Spacing washer

Bearing House

Sub-chassis plate

Bearing plate

Bearing house nuts

17 mm

Fit the motor

Fit the motor to the motor plate using the 3 small machine screws supplied. These screws should be “just” tight to keep

motor noise to a minimum. The motor fits on the underside of the motor plate – see “diagram of sub-chassis assembly”.

The motor plate is adjustable to enable optimum belt tension to be achieved – The belt tension is set by rotating the

whole motor assembly on it’s pivot point. The motor is held in position by the friction of the pivot assembly. If for any

reason this becomes slack you may need to tighten up the pivot bolt. Ideally the centre of the pulley should be

approximately 124mm from the centre of the bearing house. Generally the optimum position is such that marker bolt in

the “slot” is located at approx the mid point of the slot and this provides a useful reference point. Install Sub-chassis &

Fit springs

Fit the Sub-Chassis

Offer up the sub-chassis assembly into the plinth and fit the springs as shown in the “ diagram of support rods and

spring arrangement”. Each particular spring is of a different compliance and should be in the positions shown in the

“diagram showing spring positions

Diagram showing spring positions

MEDIUM

SPRING

POSITION

THICK

SPRING

POSITION

THIN

SPRING

POSITION

Dress the motor wires

Screw one of the cable clips onto the inner side wall of the left hand side of the plinth (see “top view of wiring layout and

connections”) such that it holds the input and motor wires (brown, blue, red & black) away from the sub-chassis and any

danger of restricting it’s movement. For full details on the motor and power supply set up read the relevant section

contained later in this manual.

Install the arm