Origin Live Building a turntable almost from scratch User Manual

Page 12

12

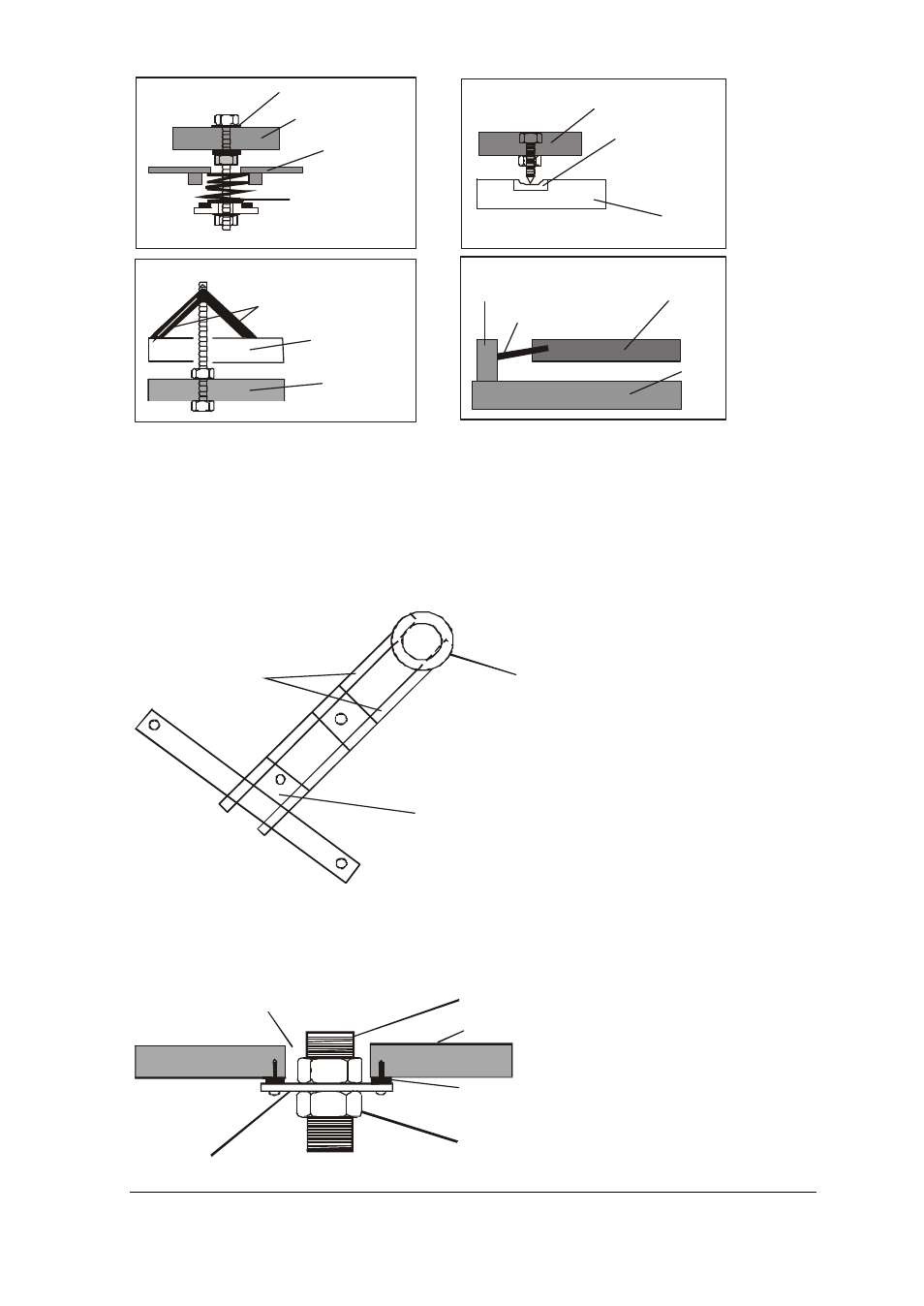

Example D

Cantilever struts

Post

Carbon fibre rod

Sub-chassis

Plinth

Example C

Rubber bands 1-10 off

Sub-chassis

Plinth

Example A

Rod

Plinth top plate

Sub-chassis

Spring

Example B

Sub-chassis

Cupped insert

(optional)

Plinth

The sub-chassis design is highly critical for performance. Conceptually the ideal solution is a rigid frame of low resonance

supported at a point half way between the arm base and platter spindle (this point is ultimately the centre of force

between the cartridge and bearing). Both the bearing house and arm base should be rigidly decoupled from the sub-

chassis. To achieve this we suggest an open frame of steel angle bar bolted together with Allen bolts - See below (welding

or gluing does not appear to work well). A sheet of aluminium plate cut with a jig-saw is simpler and can be stiffened by

bolting on steel angle bar. Whatever your final design, it is recommended that you decouple the arm and bearing house

by means of plates bolted separately to the main sub-chassis assembly. A bearing plate is supplied with the kit for this

purpose.

25 mm Angle bar

Arm board plate

Bearing house plate

If you are using the spring kit please see “Diagram of support bolts and spring arrangement” in the section describing the

Ultra kit assembly. This shows how the springs are fitted and seat into a sub-chassis.

Main Bearing attachment

The main bearing is attached as shown in diagram below or in a similar manner.

Bearing House

Plinth

De-coupling brass washer

Nut

Bearing plate

Hole 1.5” Dia or larger