Origin Live Building a turntable almost from scratch User Manual

Page 16

16

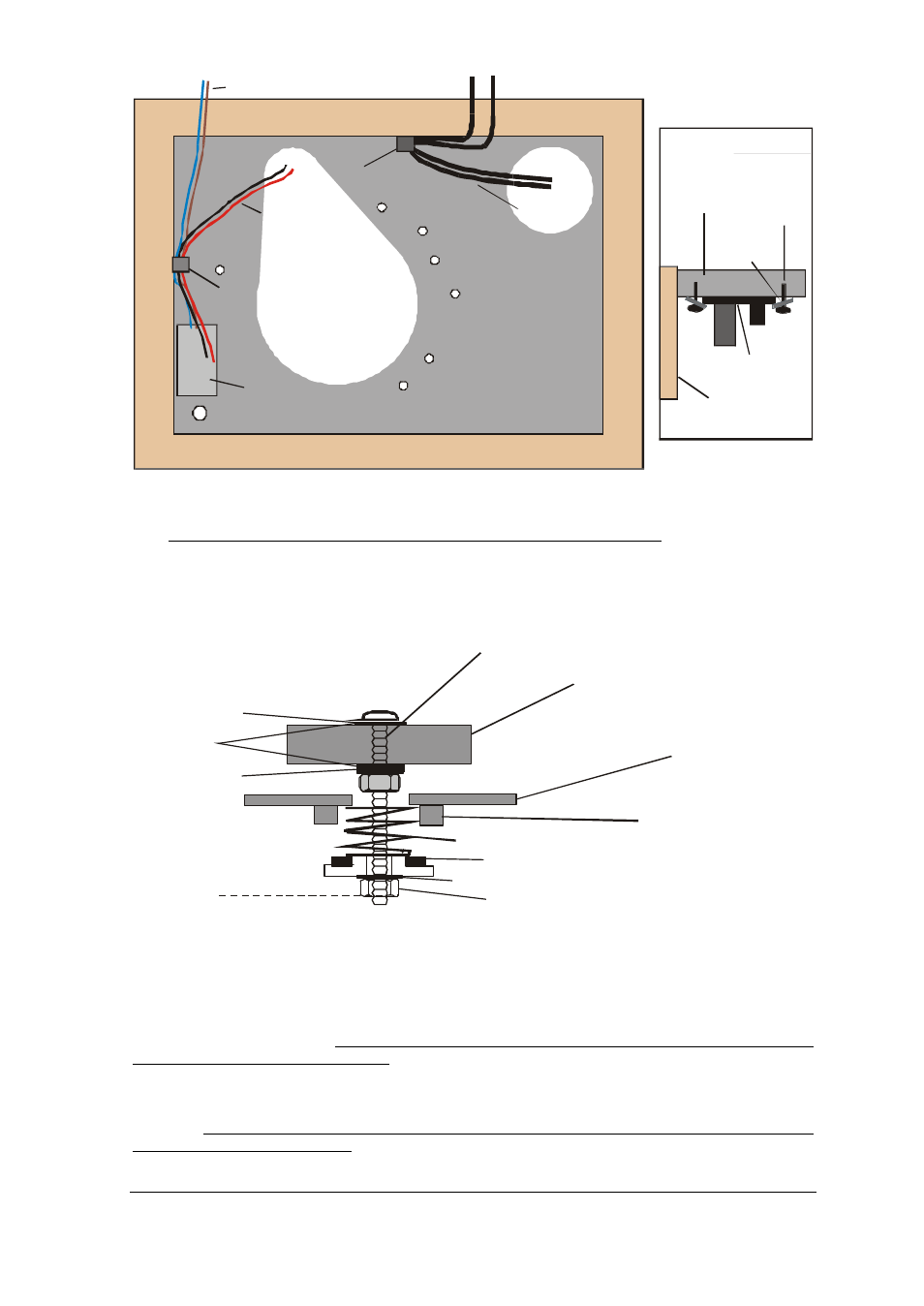

INPUT WIRES

MOTOR WIRES

CABLE CLIP

CABLE CLIP

DC REGULATOR

BOARD

ARM LEADS

DETAIL OF

DC REGULATOR

BOARD FIXING

STANDARD

TOPBOARD

SCREW

REGULATOR

BOARD

CLAMPING

WASHER

PLINTH SIDE WALL

Fit the 3 threaded support bolts

Fit the three M5 x 80mm threaded machine screw bolts (which support the springs) to the plinth top board as shown

below. Only “nip” the nuts tight by a maximum of 1/8 th of a turn after finger tightness has been achieved and they

start to clamp onto the wood. You will probably need to check these have not slackened off after about 2 months as they

tend to “bed into the wood initially.

Diagram of support bolts and spring arrangement

Serrated washer

Plain washer

Serrated washer

5mm Dia support Bolt

Plinth topboard

Sub-chassis

ring glued on supplied

Note - Small ring in thin

spring position

Spring

Rubber

Serrated washer

Nut to adjust

suspension height

Install the sub-chassis

Fit Bearing house

Fit the bearing house to the sub-chassis as shown below - only "nip" the nuts tight with a pair of pliers - more force than

this is detrimental to performance - the top of the bearing house should be between 3mm and 8mm from the top of the

bearing house nut – 3mm is probably ideal. Please note that ALL the bolts on the Sub-chassis assembly are carefully

torqued to a correct tension at factory – DO NOT TIGHTEN ANY ALLEN BOLT SETTINGS OR IT WILL

DEGRADE THE PERFORMANCE. ”. The sub-chassis is attached to the “spring plate” by one “pivot bolt” - the two

plates should be free to swivel and are loosely restrained by an “anti-rotate bolt” - this locating bolt on the side of the

sub-chassis should not be tightened at all. The pivot bolt is tightened at factory and should not be tightened or the

performance will degrade significantly.