Install-center door-w-ohcc, Figure 1 figure 2 figure 3 – Oldcastle BuildingEnvelope Thermal Clad Door and Frame User Manual

Page 21

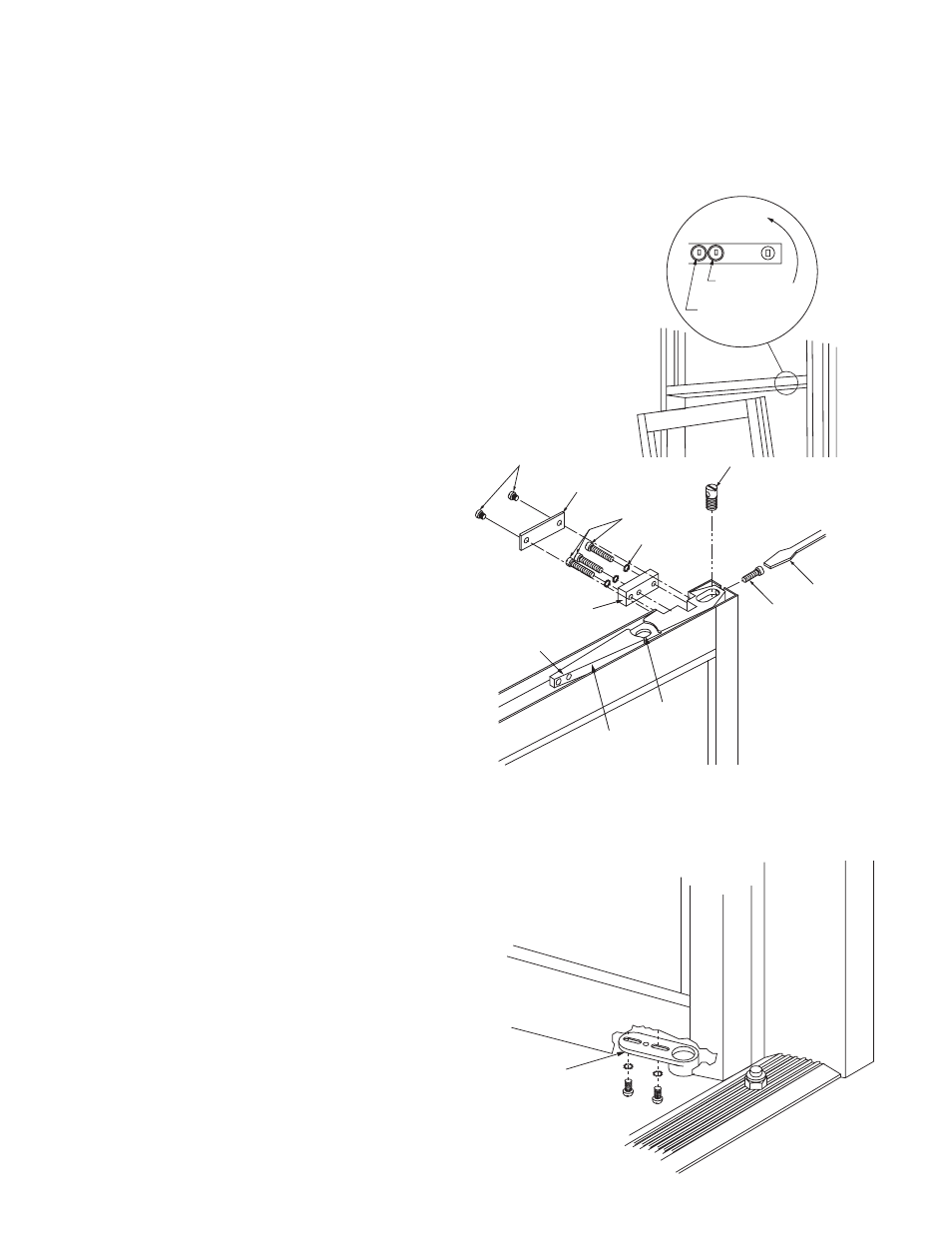

INSTALLATION OF CENTER HUNG DOOR WITH

STANDARD CONCEALED CLOSER

D O O R A N D F R A M E

1. With closer mounted in transom, (see Frame

instructions) make sure it is in hold-open position.

When closer has no hold-open feature, the follow-

ing “dogging” method applies:

A. Rotate closer spindle to 90º (either R.H. or

L.H.) with a wrench for door installation, or

rotate with door, when removing closer from

existing installation.

B. Insert suitable 5/32" diameter hard pin or nail

through 3/16" hole in base plate (located on

direct line between pivot and pivot jamb) (See

fig. 1)

C. The pin should go through base plate, lower

bushing plate at closer and hole in dogging

cam (some back and forth movement of door

or wrench may be necessary to locate this

hole. The pin should be inserted at least 1

1/2" into closer.

D. Holding the pin in place, release door or

wrench gently. Closer will be held at 90º.

2. Lift door onto floor pivot making sure of pin

engagement. Place door upright in the 90º open

position corresponding to the position of the indi-

cator mark on the closer shaft.

3. Push top arm of door against closer shaft.

4. Apply top clamping block per label at top of door,

with two socket head cap screws using 7/32" hex

key, but do not tighten (See fig. 2).

NOTE: If vertical adjustment of the door is required,

use a wrench to turn bottom pivot adjusting screw up

or down (See fig. 3).

CAUTION: Make sure top clamping block screws are

loose before making adjustment.

5. Return to top clamping block and TIGHTEN sock-

et head cap screws SECURELY and EVENLY per

the torque label on the top corner of door.

CAUTION: Be sure to remove pin before trying to

operate closer. To remove pin, open closer from

dogged position slightly to remove spring force

from pin. Remove pin and gently release closer.

6. Insert weathered end trim cap at top and secure

to door with screw.

7. To operate, push door out of hold open position.

(If model has no hold open, remove dogging pin

and gently release closer.)

8. Glaze door. (See page 15)

9. Check top arm centering screws for snug contact

with the sides of the top rail.

CAUTION: Over-tightening will bulge the top rail.

Check tightness of arm anchoring screws.

If the door does not center in the frame after

being operated a few times, loosen the top arm

anchor screws, readjust the centering screws (do

not bulge sides of top rail) and retighten the

anchor screws.

10. Adjust closer closing speeds and latching speeds.

(See Adjustment Instructions packed with Closer.)

Figure 1

Figure 2

Figure 3

Adjust door by turning adjusting

screw clockwise to lower door

or counterclockwise to raise

door. When proper setting is

achieved tighten top arm

attachment screws.

CLOSING

SPEED SLOW

LATCHING

SPEED

FAST

*PLATE SCREW

*DRESS PLATE

*LOCK WASHER

*ARM STUD

*ARM CLAMPING SCREW

(1/4-20 X 7/8" CAP SCREW)

ADJUST POSITION

WITH FLAT BLADE

SCREW DRIVER

*ARM ADJUSTING

SCREW

ARM HOLDING

SCREW

CLOSER ARM

FACTORY INSTALLED

CENTERING

SCREWS

*CLAMPING BLOCK

BOTTOM

PIVOT BLOCK

21

MAY 2012

D O O R & F R A M E

I N S T A L L A T I O N M A N U A L

Web Address: www.oldcastlebe.com

Phone: 1-866-OLDCASTLE (653-2278)