Pressure-plate-glazing – Oldcastle BuildingEnvelope Reliance FRP User Manual

Page 6

5

R E L I A N C E C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

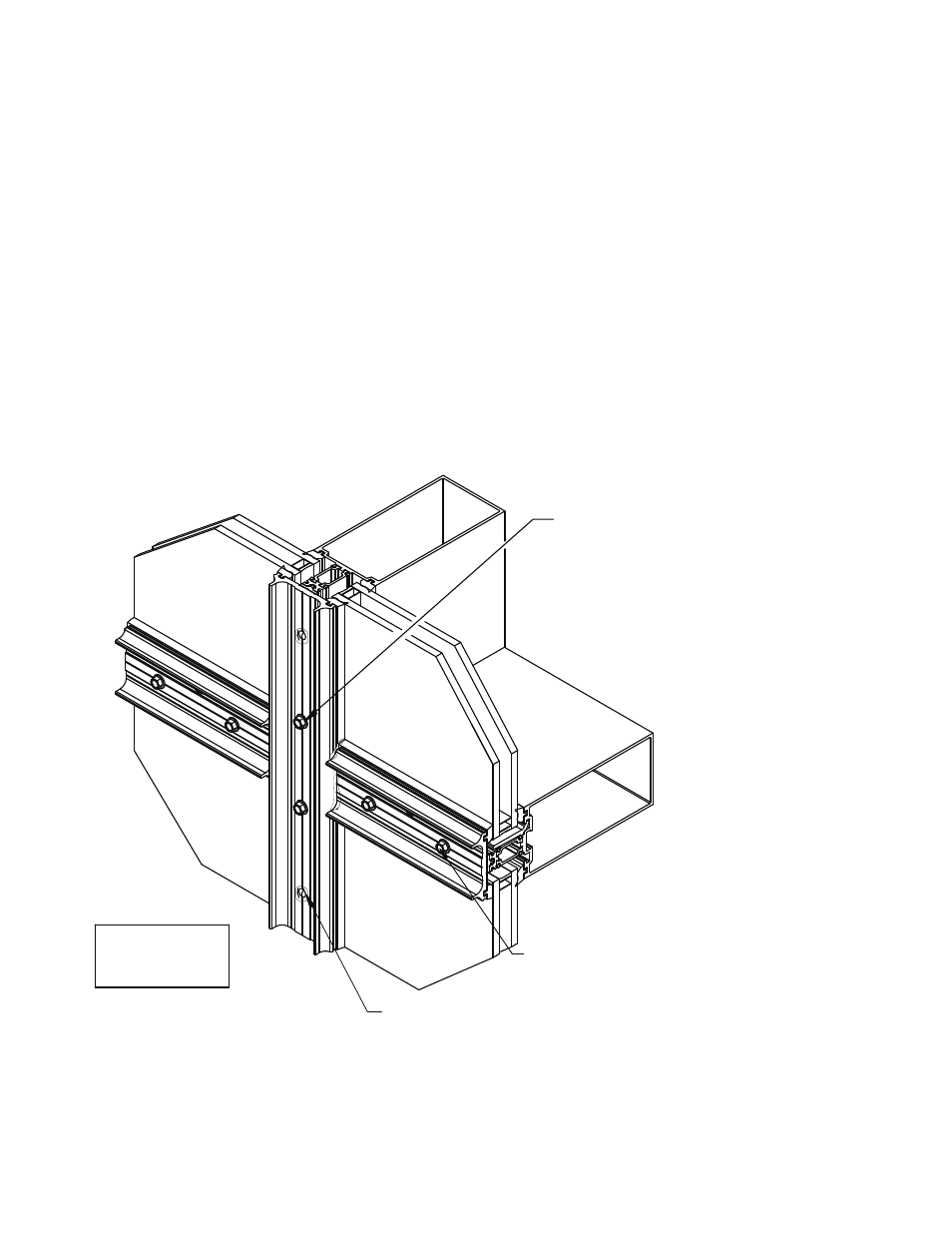

FS-325 Drillflex fastener

Locate at 9" o.c. typical

Torque to 80 in/lbs.

Fastener to be located at

maximum 3" above and below

the center line of each horizontal

Seal all unused

holes in pressure

plate

2.1 When installing AW-162 FRP pressure plate follow all standard installation steps as noted in appropriate

Reliance

™

system installation and glazing manual. Install fasteners located at 12" from each end first. then end

fasteners in pressure plates last, be sure to hold firm pressure on pressure plate while installing the FS-325

fasteners to prevent pressure plate from pulling away from face of system and disengage the thermal isolator.

Torque fasteners to 80 in/lbs. Fasteners will be located at a maximum of 9" on center. Fastener location may vary

based on project specifications, so consult shop drawings for additional information. Additional fasteners should

be added where needed to insure a fastener is located above and below each horizontal.

See FIGURE 3

2.2 All unused holes in vertical and horizontal pressure plates must be sealed.

See FIGURE 3

2.3 Seal horizontal pressure plate to verticals and install face caps. Reference system installation manuals for

more information. See FIGURE 4, page 6.

2.4 Horizontal face caps are to be cut D.L.O. minus 1/16". Drill 5/16" weep hole on bottom of cap at centerline.

See FIGURE 5, page 6.

FIGURE 3

Sealant and Fastener

Locations

FRP PRESSURE PLATE

GLAZING

Install fasteners beginning

with hole at 12" from each

end. Install end fastener last.

See instructions above.

Note: Vertical cover

omitted to show

fastener locations.

™