Pressure-plate-fabrication – Oldcastle BuildingEnvelope Reliance FRP User Manual

Page 5

4

R E L I A N C E C U R T A I N W A L L I N S T A L L A T I O N M A N U A L

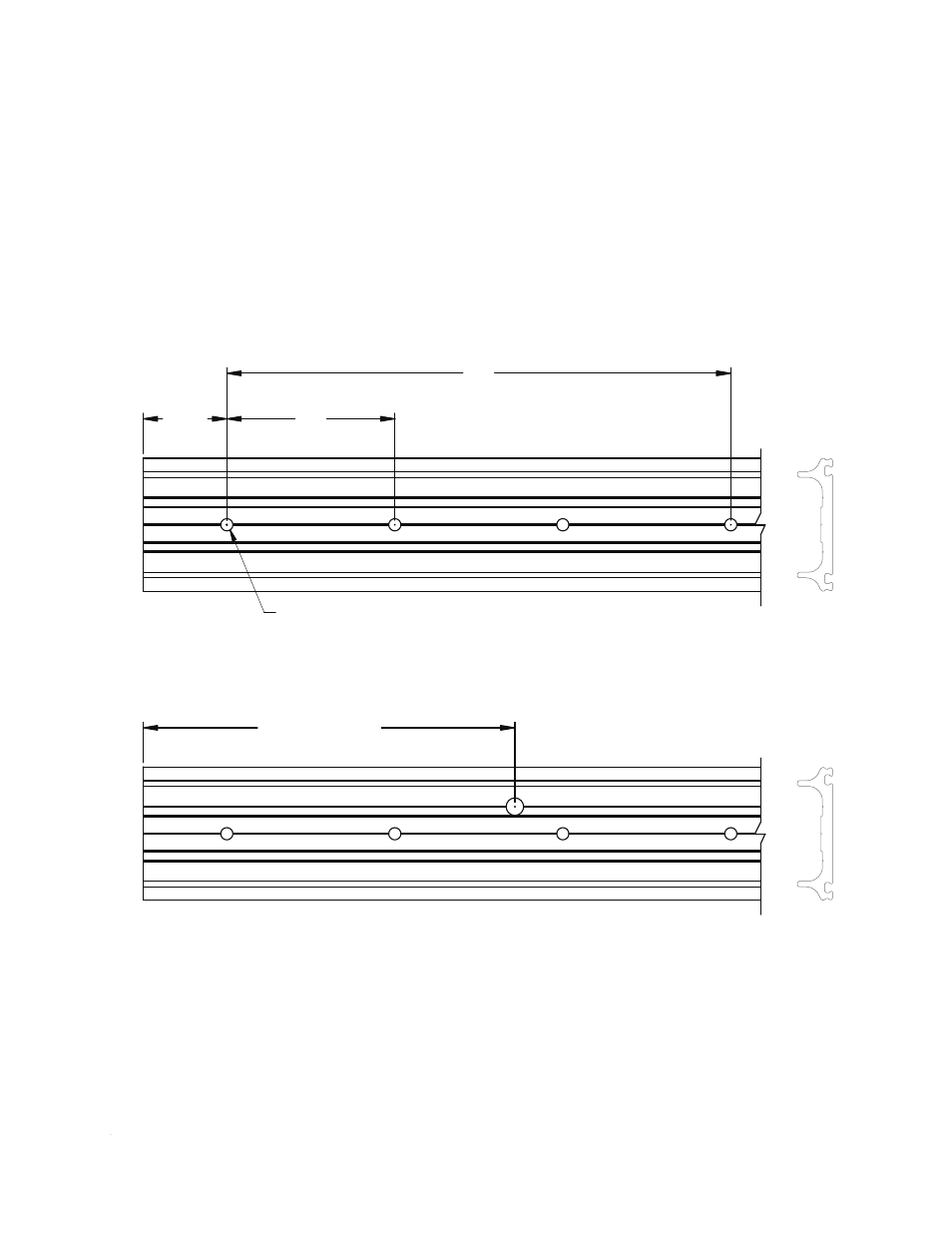

1.1 Pressure plate is pre-fabricated with 7/32" holes at 3" on center. Fasteners will be installed at 9" on center and

should be located at maximum 1-1/2" from ends. Additional fasteners may be required based on project

specifications. If additional holes are required use a 15/64" (.234) drill. (See notes below for drill bit recommendations)

See FIGURE 1 Cut length of pressure plate will be mullion height for verticals and D.L.O. minus 1/4" for horizontals.

1.2 Weep holes are to be located at 1/4 points of horizontal pressure plates unless shop drawings designate

different locations. Weep holes are 5/16" diameter (See notes below for drill bit recommendations.).

See FIGURE 2

FIGURE 1

Attachment Holes

Fabrication Notes:

1) Standard drill bits may be used to drill fiberglass, but life of bit will be reduced. It is recommended that a masonry

drill bit be used.

2) The pressure plate may be cut using a carbide blade but due to the high content of fiberglass in the pressure plate,

blade life will be significantly shortened. It is recommended that a diamond tipped blade be used.

FIGURE 2

Weep Holes

11/2"

3"

9"

1/4 Points typical

FRP PRESSURE PLATE

PRESSURE PLATE FABRICATION

7/32" Ø holes

™