Manual override, Proportional and tri-state, Two-position spring return – KMC Controls VEZ-4x Series User Manual

Page 3: Caution

VEZ-4x Series, 2-Way/3-Way, NPT Zone Control Valves (1/2 to 1")

3

Installation Guide

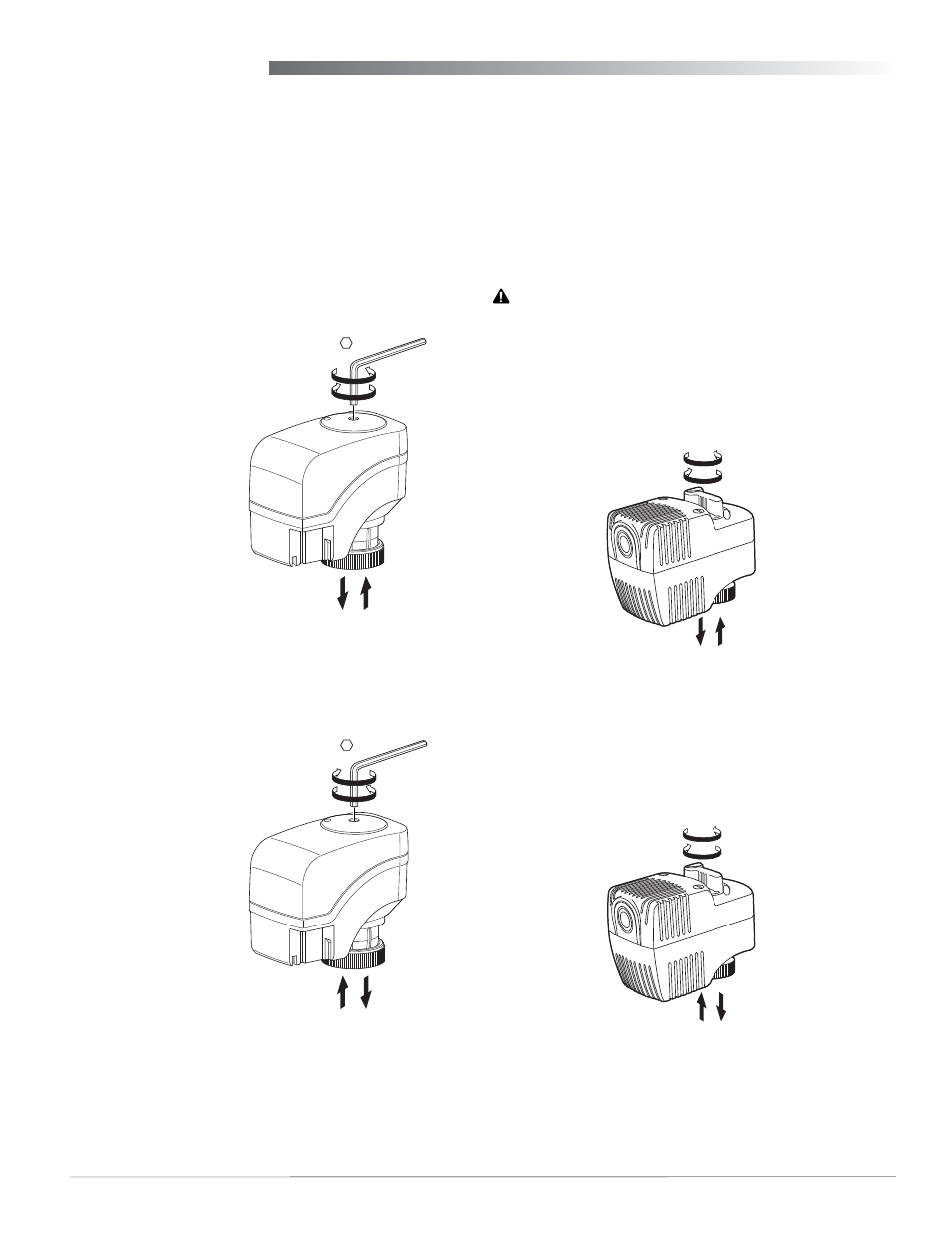

(A) Allow handle to turn counterclockwise

to extend spindle and close valve (AB-B).

(B) Turn handle clockwise to retract spindle

and open valve (AB-A).

B

A

B

A

B

A

(A) Allow handle to turn counterclockwise

to retract spindle and open valve (AB-A).

(B) Turn handle clockwise to extend spindle

and close valve (AB-B).

B

A

B

A

Fail-Safe (Spring Return)

Actuator “M” MEP-3503 (NO or Fail AB-A)

Actuator “P” MEP-3504 (NO or Fail AB-A)

Fail-Safe (Spring Return)

Actuator “N” MEP-3501 (NC or Fail AB-B)

Actuator “Q” MEP-3502 (NC or Fail AB-B)

B

A

B

A

3 mm

B

A

B

A

3 mm

(A) Turn the hex wrench

clockwise and the

spindle extends (2-way valve closes).

(B) Turn the hex wrench

counterclockwise and the

spindle retracts (2-way valve opens).

Proportional Actuator “B”

MEP-3511

(NC or Fail-in-Place)

Proportional Actuator “A”

MEP-3516

(NO or Fail-in-Place)

(B) Turn the hex wrench

clockwise and the

spindle extends (2-way valve closes).

(A) Turn the hex wrench

counterclockwise and the

spindle retracts (2-way valve opens).

Tri-State Actuator “F”

MEP-3510

Manual Override

For manual positioning, turn off power to the actua-

tor, rotate the manual override handle clockwise

180°, and squeeze the handle to latch it around the

protruding stop. (The actuator will automatically

unlatch when power is applied.)

The “0” and “1” positions on the housing are for

reference only and are not for stroke measurement.

CAUTION

To avoid damaging the actuator, do not manually

assist the spring return as it returns to its home

position.

Two-Position Spring Return

Proportional and Tri-State

For manual positioning, turn off power to the actua-

tor and use a 3 mm hex wrench to rotate the actuator.

The actuator will maintain its position until power is

restored and a control signal is applied.

Cycling the power off and then back on recalibrates

the actuator.

The “0” and “1” positions on the housing are for

reference only and are not for stroke measurement.