KMC Controls VEP-45 Series User Manual

Installation guide, Way, npt, control ball valves, Mounting

VEB-43/VEP-45 Series 2-Way (1/2 to 3") NPT Control Ball Valves

1

Installation Guide

Mounting

NOTE: To assemble a quick-mount “V” actuator on

a valv

eb site.

Installation Guide

2-Way, NPT, Control Ball Valves (

1

⁄

2

to 3")

VEB-43/VEP-45 Series

Mounting 1

Wiring 1

Operation 2

Maintenance 2

Important Notices 2

More Information 2

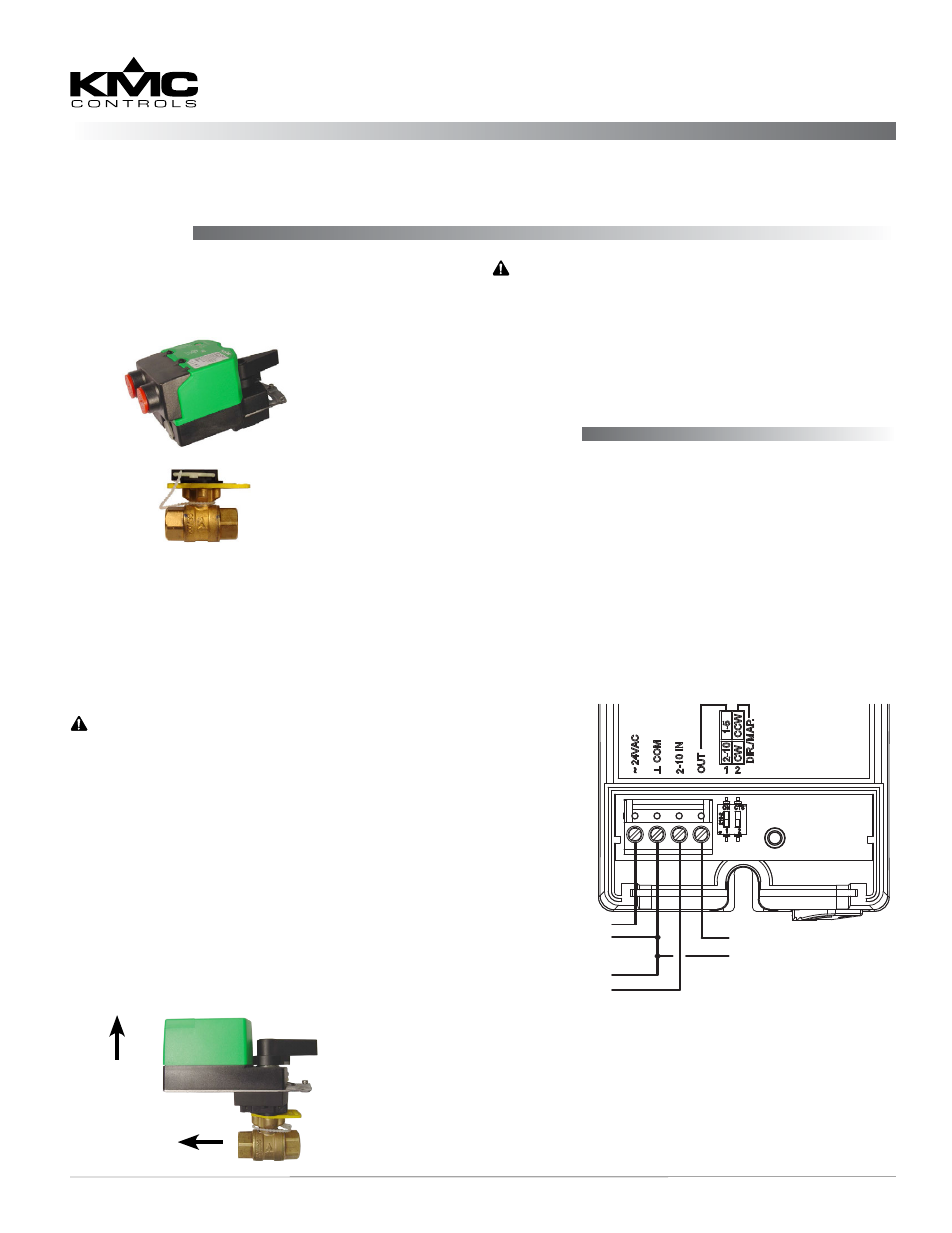

UP

SYSTEM FLOW

ACTION:

Full CW = Valve Closed

Full CCW = Valve Open

CAUTION

Using mineral oil lubricants or other incompatible

substances in system fluids may damage EPDM

rubber seals in valves. Before using any lubricant or

additive in a water or ethylene glycol base, consult

the substance manufacturer for compatibility with

EPDM (Ethylene Propylene Diene Monomer).

Wiring

NOTE: The installed actuator model is indicated

by the last two digits of the VEB valve

model number (e.g., VEB-43xxxxCK

has an MEP-4002V actuator) and the

last three digits of the older VEP valve

model number (e.g., VEP-45xxx745 has an

MEP-4002 actuator). For wiring and other

information about tri-state and other

actuators no longer sold mounted on

these valves, see the respective actuator’s

installation guide on the KMC web site.

VFB-43 Series

Valve Body

MEP-4x5xV

Actuator

1. Clean the lines upstream from the valve. Remove

any debris larger than 0.06" (0.015 mm).

2. Align the valve’s flow indicator with the system

flow.

3. Mount the valve so the actuator is positioned over

valve.

CAUTION

To prevent condensation from dripping onto the

actuator housing, mount the valve with the actuator

in the upright position or, at most, at a 45° angle.

4. Seal valves with approved pipe sealant.

5. Using two wrenches, secure the valve to the pipe.

Torque should not exceed 75 ft-lb. (102 N

•

m).

6. Eliminate air from the system to keep the valves

full of fluid during operation.

NOTE: If the system experiences large amounts of

debris, steps should be taken to keep the

system clean.

CK/745 Wiring (MEP-4002)

NOTE: Before January 2014, MEP-40x2/48x2

models had 0–10 VDC inputs. They now

have 2–10 VDC inputs. When replacing an

older 0–10 VDC actuator with a 2–10 VDC

actuator, configure the connected controller

or thermostat output to match.

Power

Supply

~

–

–

+

Control Signal

2–10 VDC

–

+ Feedback Output

1–5 or 2–10 VDC